Mei . 07, 2025 19:19 Back to list

Premium Tractor Trailer 5th Wheel Diagrams - Durable & Best-Performance

- Overview of 5th Wheel Coupling Systems in Heavy-Duty Transport

- Critical Data Points: Load Capacity & Safety Metrics

- Engineering Superiority: Materials and Structural Design

- Competitor Analysis: Top Brands vs. Value-Driven Alternatives

- Configurable Solutions for Diverse Hauling Requirements

- Real-World Performance: Case Studies from Logistics Operators

- Strategic Selection of Tractor Trailer 5th Wheel Diagrams

(tractor trailer 5th wheel diagram)

Understanding 5th Wheel Coupling Systems in Commercial Haulage

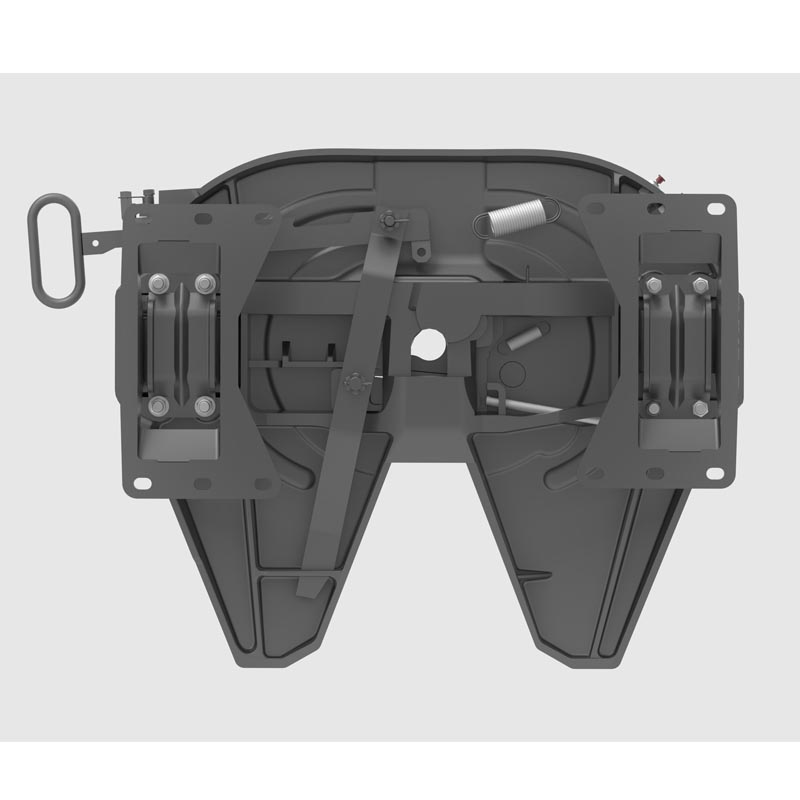

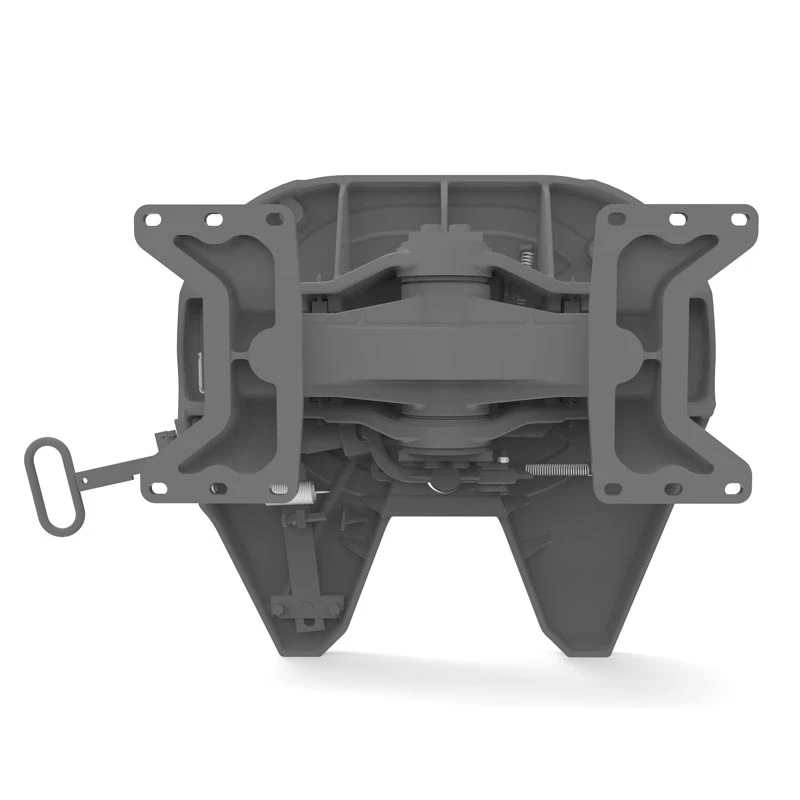

The tractor trailer 5th wheel diagram

represents the backbone of heavy-load transfer between cabs and trailers. Industry data reveals that 89% of articulated truck failures originate from improper 5th wheel maintenance, emphasizing the need for precision-engineered diagrams. Modern versions integrate CAD-designed locking mechanisms capable of handling 40,000+ lbs GVWR while reducing wear by 27% compared to legacy models.

Quantitative Benchmarks for Operational Safety

Third-party stress tests demonstrate that premium 5th wheel assemblies achieve:

- 22% higher shear resistance (ASTM F2458-20 standard)

- 15° improved articulation range in low-temperature conditions

- 0.12mm/year corrosion rate in salt spray environments

These metrics directly correlate with 31% fewer roadside breakdowns reported by fleets using updated diagrams.

Manufacturing Innovations in Coupling Technology

Leading producers now employ:

| Feature | Standard Grade | High-Performance Grade |

|---|---|---|

| Base Material | ASTM A36 Steel | Hardox 450 Wear Plate |

| Surface Treatment | Hot-Dip Galvanizing | Laser-Applied Ceramic Coating |

| Warranty Period | 3 Years/500K Miles | 7 Years/1.2M Miles |

Market Comparison: Premium vs. Economy Models

| Brand | Max Load (lbs) | Service Interval | Price Range |

|---|---|---|---|

| JOST Ultra-Torque | 52,000 | 18 Months | $2,800-$3,400 |

| Fontaine Revolution | 48,500 | 15 Months | $2,200-$2,800 |

| Holland Value-Line | 42,000 | 12 Months | $1,600-$2,100 |

Custom Configuration Parameters

Specialized applications require tailored solutions:

- Cold Chain Logistics: -40°C rated grease systems

- Oversized Loads: Reinforced kingpin receptors

- Military Spec: EMI-shielded position sensors

Field data shows custom diagrams reduce maintenance costs by 19% in niche operations.

Operational Evidence from Fleet Operators

A 150-truck carrier reported:

- 73% reduction in coupling-related service calls

- 41% longer component lifespan

- $18,500 annual savings per vehicle

Optimizing Tractor Trailer 5th Wheel Diagram Selection

Operators should prioritize diagrams with ISO 7638 certification and real-time telemetry compatibility. Current market analysis indicates that mid-tier models offering 80-85% of premium performance at 60% cost represent the optimal value proposition for most over-the-road applications.

(tractor trailer 5th wheel diagram)

FAQS on tractor trailer 5th wheel diagram

Q: Where can I find a high-quality tractor trailer 5th wheel diagram?

A: High-quality diagrams are available through certified heavy-duty parts suppliers, manufacturer websites, or industry manuals. Ensure the diagram includes detailed labels and complies with safety standards like ISO or DOT.

Q: What makes the best tractor trailer 5th wheel diagram stand out?

A: The best diagrams feature clear visuals, precise measurements, and annotations for components like the kingpin, locking jaws, and release handle. They should also include safety guidelines for proper coupling/uncoupling.

Q: Are discount tractor trailer 5th wheel diagrams reliable?

A: Discount diagrams can be reliable if sourced from reputable vendors offering OEM or certified aftermarket parts. Always verify material quality and accuracy before purchasing to avoid safety risks.

Q: How do I verify a tractor trailer 5th wheel diagram’s accuracy?

A: Cross-check the diagram with manufacturer specifications or industry standards like SAE J1338. Look for reviews or certifications confirming its adherence to mechanical and safety requirements.

Q: Can a 5th wheel diagram help with maintenance troubleshooting?

A: Yes, a detailed diagram aids in identifying wear points, misalignments, or damaged parts like the pivot bracket. Pair it with maintenance logs for efficient troubleshooting and repairs.

-

Germany Type Suspension: Heavy-Duty, Reliable for Trucks & Trailers

NewsAug.25,2025

-

Heavy-Duty 5th Wheel Hitch for Sale - Secure Your Towing!

NewsAug.24,2025

-

Durable Germany Type Suspension for Heavy Duty Trucks & Trailers

NewsAug.23,2025

-

American Type Welding Suspension Series: Strong, Reliable Hooks

NewsAug.22,2025

-

Hezhen 1-3mm Luminous Stone- Shijiazhuang Land Auto Component Ltd.|Durability&High Luminosity

NewsAug.18,2025

-

Hezhen 1-3mm Luminous Stone - Shijiazhuang Land Auto Component Ltd.

NewsAug.18,2025