авг. . 09, 2025 00:40 Back to list

Premium Germany Type Suspension – Reliable & Heavy-Duty

In the demanding world of heavy-duty transportation, the efficiency, safety, and longevity of commercial vehicles hinge significantly on the quality of their suspension systems. Among the myriad options available, the Germany Type Suspension stands out as a benchmark for engineering prowess, robust design, and unparalleled reliability. Engineered to withstand extreme loads and harsh operating conditions, these suspension systems embody decades of German precision and innovation, making them a preferred choice for fleet operators and manufacturers globally.

This comprehensive guide delves into the intricate world of Germany Type Suspension, exploring its foundational principles, advanced manufacturing techniques, diverse applications, and the tangible advantages it offers. We will provide a deep dive into industry trends, technical specifications, and real-world performance, empowering stakeholders to make informed decisions for their heavy vehicle fleets.

Industry Trends and the Evolution of Heavy-Duty Suspensions

The global logistics and transportation sector is undergoing rapid transformation, driven by increasing e-commerce, infrastructure development, and the need for more efficient and sustainable freight movement. This evolution places immense pressure on vehicle components, demanding higher performance, lower maintenance, and extended lifespans. Traditional leaf spring suspensions, while cost-effective, often fall short in providing optimal ride comfort, stability, and tire longevity for modern high-speed or heavy-haul operations. Air suspensions offer superior comfort but can be more complex and costly to maintain, alongside often having a higher initial investment and requiring more sophisticated electronic management systems.

Against this backdrop, the Germany Type Suspension has solidified its position as a robust and reliable alternative, particularly for applications requiring high load bearing capacity and exceptional durability. The trend in the heavy-duty segment is moving towards integrated solutions that offer a precise balance of ruggedness, operational efficiency, and reduced total cost of ownership (TCO). There's a growing emphasis on modular designs that simplify assembly and replacement, the adoption of lighter yet stronger materials without compromising structural integrity, and components that contribute to better fuel economy through reduced rolling resistance and improved aerodynamics (indirectly by maintaining optimal vehicle height and stability under varying loads).

Furthermore, advancements in materials science, such as high-strength low-alloy (HSLA) steels and sophisticated composites, are enabling the development of suspension components that are both lighter and stronger, offering enhanced fatigue life and corrosion resistance. Precision manufacturing processes, including advanced robotic welding techniques, state-of-the-art CNC machining, and meticulously controlled heat treatment, ensure consistent quality, tighter dimensional tolerances, and superior surface finishes. This leads to improved performance metrics, extended service intervals, and greater reliability in extreme conditions. While purely mechanical, the design principles of the Germany Type Suspension are influenced by a broader industry push for components that contribute to overall vehicle optimization, including enhanced safety features and reduced environmental impact through prolonged component life and efficiency gains.

Data from recent market analyses underscore the robust demand for reliable, low-maintenance suspension systems in the heavy-duty sector. For instance, reports by Statista indicate a consistent growth trajectory for the global heavy-duty truck market, directly correlating with the need for high-performance components. Similarly, a comprehensive analysis by Grand View Research projects significant expansion in the global automotive suspension system market, with the heavy commercial vehicle segment being a key driver. This growth is propelled by increasing freight volumes, infrastructure development projects worldwide, and stringent safety regulations, all of which align perfectly with the core strengths and enduring appeal of the Germany Type Suspension.

Understanding the Core of Germany Type Suspension

At its heart, the Germany Type Suspension system is a meticulously engineered mechanical suspension designed primarily for heavy-duty commercial vehicles, including trucks, trailers, and specialized transport equipment such as low-loaders and multi-axle modular transporters. Unlike more complex air suspension or certain independent coil spring setups, it typically relies on a robust combination of multi-leaf springs, an equalizer beam (also known as a rocker arm), and sturdy hangers and shackles. This design approach prioritizes brute strength, load-bearing capacity, and resilience, making it exceptionally well-suited for the most demanding applications where reliability in extreme conditions is paramount.

Key Components and Their Functions:

- Multi-Leaf Springs: These are the primary load-bearing and shock-absorbing components. Composed of multiple layers (leaves) of high-grade spring steel, stacked in descending order of length, they flex under load to provide support and cushioning. The specific number of leaves, their thickness, and material composition are engineered to match the intended load capacity and ride characteristics. The quality of steel and the meticulous manufacturing processes, such as precise heat treatment and shot peening, are critical for achieving high fatigue life and preventing permanent deformation under cyclic loading.

- Equalizer Beam (Rocker Arm): This is a pivotal component, especially in tandem or tridem (multiple) axle configurations. The equalizer beam connects the leaf springs of adjacent axles, allowing for dynamic load equalization between them. As one wheel encounters an obstacle or dip, the equalizer beam pivots, distributing the load more evenly between the axles. This mechanism is crucial for maintaining vehicle stability, improving traction over uneven terrain, and significantly reducing premature or uneven tire wear by ensuring balanced pressure distribution.

- Hangers and Shackles: These robust, heavy-gauge steel components serve as the critical connection points between the leaf springs and the vehicle's chassis or trailer frame. Hangers are typically fixed brackets that attach one end of the leaf spring to the frame, while shackles are flexible links that attach the other end, allowing for the slight change in effective leaf spring length as it compresses and extends during operation. Their design and material strength are paramount for enduring continuous stress and ensuring long-term structural integrity and safety.

- Torque Rods (Optional/Varying Designs): Depending on the specific suspension design and desired articulation, torque rods (also known as radius rods or trailing arms) may be incorporated. These rigid bars connect the axle housing to the frame, controlling the fore-aft movement of the axle and preventing axle wrap-up under acceleration or braking. They also help maintain proper axle alignment, contributing to directional stability and further reducing tire wear.

- U-Bolts: These heavy-duty, U-shaped threaded bolts are essential fasteners that secure the leaf springs, axle assembly, and often the equalizer beam to the suspension hangers and brackets. Their robust construction and high clamping force ensure a rigid, secure, and safe connection that can withstand significant shear and tensile forces encountered during heavy haulage.

- Bushings: Located at the pivot points within the hangers, shackles, and equalizer beam connections, bushings are critical for allowing smooth articulation while minimizing friction and wear. They are typically made from durable, wear-resistant materials such as high-density polyurethane, rubber compounds, or specialized bronze alloys, designed to absorb vibration, reduce noise, and extend the service life of mating components.

Technical Parameters and Specifications:

The performance envelope of a Germany Type Suspension system is meticulously defined by a range of critical technical parameters. These specifications dictate its maximum load-bearing capacity, operational stability under various conditions, and overall suitability for specific heavy-duty transport applications. Below is a detailed table summarizing typical parameters, though it's important to note that specific values will vary significantly by the exact model, manufacturer, and intended application (e.g., whether it's for a single, tandem, or tridem axle configuration, or for a specific vehicle gross weight):

| Parameter | Typical Range for Heavy-Duty Application | Unit | Description |

|---|---|---|---|

| Axle Load Capacity | 13,000 - 16,000 (Single Axle) | kg | Maximum permissible vertical weight that the suspension system can safely support per individual axle. This is a crucial safety and performance metric. |

| Number of Axles Supported | 1, 2, 3 (Single, Tandem, Tridem) | - | Refers to the configuration of axles the specific suspension design is engineered to accommodate, impacting total vehicle load capacity and load distribution. |

| Leaf Spring Width | 75 - 100 | mm | The width of the individual steel leaves. A wider spring generally provides greater lateral stability and better load distribution across its surface. |

| Leaf Spring Thickness (per leaf) | 12 - 20 | mm | The thickness of each individual steel leaf within the spring pack. Thicker leaves contribute to higher stiffness and greater load-bearing capacity. |

| Number of Leaves per Spring Pack | 8 - 12 (or more for specialized heavy loads) | - | The total count of individual steel layers forming a complete leaf spring unit. More leaves often mean higher capacity and a stiffer ride. |

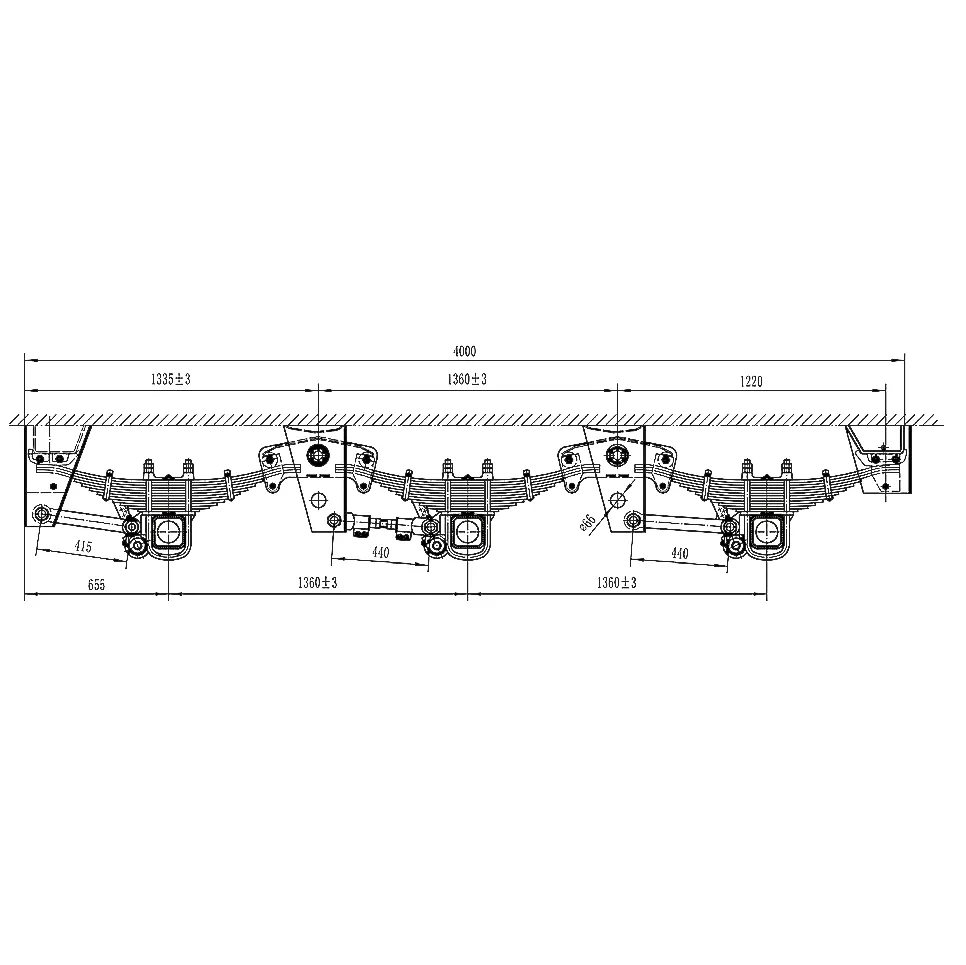

| Wheelbase Range (for multi-axle) | 1310 - 1360 (Standard) | mm | The typical distance between the centers of adjacent axles in a tandem or tridem suspension setup. Critical for vehicle geometry and maneuvering. |

| Mounting Height (H) | 125 - 200 | mm | The vertical distance from the center of the axle to the top of the suspension mounting bracket (spring seat) on the chassis. Affects vehicle ground clearance and center of gravity. |

| Primary Material Grade (Springs) | SUP9, 60Si2Mn, 50CrVA (JIS/GB/ASTM) | - | Specific high-strength alloy steels used for leaf springs, known for their excellent fatigue strength, resilience, and resistance to permanent deformation. |

| Manufacturing Standards Adhered To | ISO 9001, DIN, JIS, ASTM, IATF 16949 | - | Compliance with international and regional quality management systems and material/design specifications, ensuring consistent product quality and reliability. |

| Designed Service Life | >500,000 | km | The estimated operational lifespan of the suspension system under typical design load and road conditions, before major overhauls or replacements are expected. |

| Corrosion Protection | E-coating, Powder Coating, Multi-layer Paint | - | Types of protective surface treatments applied to components to resist rust, chemical degradation, and environmental wear, extending component life. |

These detailed parameters collectively define the robust performance envelope of the Germany Type Suspension, ensuring its capability to meet the rigorous demands of heavy haulage operations while maintaining optimal safety, stability, and operational efficiency over its extensive service life. Understanding these specifications is key for fleet managers and vehicle designers to select the most appropriate suspension system for their unique applications.

The Meticulous Manufacturing Process of Germany Type Suspension

The superior quality, renowned durability, and consistent performance of Germany Type Suspension systems are a direct result of their stringent manufacturing processes. These processes meticulously integrate advanced metallurgy, precision engineering, cutting-edge automation, and rigorous, multi-stage quality control. The production workflow typically involves a series of critical stages, each contributing significantly to the final product's strength, reliability, and extended operational lifespan.

Detailed Manufacturing Workflow:

- Material Selection and Preparation:

The foundation of a truly durable suspension system lies in the judicious selection of raw materials. For the highly stressed leaf springs, high-grade alloy steels such as SUP9, 60Si2Mn, or 50CrVA are typically chosen. These materials are specifically selected for their excellent elastic properties, high tensile strength, and exceptional fatigue resistance, enabling them to withstand millions of load cycles without permanent deformation or brittle fracture. For structural components like hangers, equalizer beams, and brackets, high-strength low-alloy (HSLA) steels are preferred due to their superior strength-to-weight ratio, excellent weldability, and formability. Reputable manufacturers source these materials exclusively from certified mills, ensuring full compliance with international standards such as ASTM, DIN, JIS, or EN specifications. Upon arrival at the manufacturing facility, all raw materials undergo initial, thorough quality inspection, including chemical composition analysis (e.g., via Optical Emission Spectrometry) and mechanical property verification (e.g., hardness testing, tensile strength testing) to confirm they meet stringent design requirements.

- Cutting and Forming:

Raw steel bars designated for leaf springs are precisely cut to predetermined lengths using highly accurate automated shearing machines or advanced laser cutting technology, ensuring minimal material waste and dimensional consistency. For complex components such as hangers and equalizer beams, steel plates are precisely cut using high-definition CNC plasma or laser cutting systems, which enable the creation of intricate shapes with extremely tight tolerances. Subsequently, the individual leaf spring strips undergo specialized forming processes: they are tapered (rolled to a variable thickness along their length for optimal stress distribution) and eye-rolled (where the ends of the springs are precisely coiled to form the 'eyes' through which connection pins or bushings are inserted). This critical cold or hot forming process ensures the correct curvature and profile for ideal load distribution and flex characteristics.

- Heat Treatment (Quenching and Tempering):

This is arguably the most pivotal stage for leaf springs, transforming the steel's metallurgical structure to achieve its ultimate mechanical properties. After initial forming, the leaves are heated uniformly to a specific austenitizing temperature (typically between 850°C and 900°C) in precisely controlled-atmosphere furnaces. This ensures a homogeneous crystalline structure. Immediately following heating, the leaves are rapidly quenched in specialized oil or polymer solutions. This rapid cooling transforms the steel into a hard, but brittle, martensitic structure. To mitigate this brittleness and impart the necessary toughness and elasticity, the leaves then undergo a tempering process. They are reheated to a lower, precise temperature (e.g., 400°C to 550°C) and held for a specific duration. This tempering refines the martensite, significantly enhancing the spring's ductility, toughness, and crucial elastic properties, while optimizing its resistance to fatigue. Advanced pyrometric systems and continuous monitoring ensure precise temperature and time control throughout these critical thermal cycles.

- Shot Peening:

Following heat treatment, the surfaces of the leaf springs, particularly those under tensile stress during operation, are subjected to a process called shot peening. This involves bombarding the spring's surface with a stream of small, high-velocity steel or ceramic shots. Each shot creates a tiny indentation, plastically deforming the surface layer and inducing a localized compressive residual stress. This intentionally created compressive layer acts as a barrier, significantly inhibiting the initiation and propagation of micro-cracks under cyclic loading. This process dramatically enhances the fatigue resistance and extends the overall service life of the leaf springs, which is paramount for high-stress, high-cycle heavy-duty applications.

- Assembly and Welding:

Once individual components like heat-treated leaf springs, formed hangers, and equalizer beams are processed and surface-treated, they move to the assembly line. Hangers and equalizer beams are typically fabricated through a combination of precise stamping, bending, and highly automated robotic welding. Robotic welding systems are extensively utilized to ensure consistent, high-strength welds with minimal thermal distortion, adhering rigorously to international welding standards such as AWS D1.1 (Structural Welding Code – Steel) or ISO 3834. The individual leaf springs are then assembled into complete packs, often incorporating inter-leaf liners (made from materials like nylon or polypropylene) to reduce friction, noise, and wear between leaves. Finally, the spring packs are securely connected to the hangers and equalizer beams using robust fasteners and high-tensile U-bolts. Wear-resistant bushings, made from materials such as high-density polyurethane, natural rubber, or self-lubricating bronze, are carefully inserted into the spring eyes and hanger bores to facilitate smooth articulation and minimize frictional wear at pivot points.

- Machining (CNC Processing):

Critical interfaces, mounting points, and bearing surfaces on components like hangers, equalizer beams, and axle seats undergo high-precision machining. This is typically performed using Computer Numerical Control (CNC) milling, drilling, and turning machines. CNC processing ensures exceptionally exact dimensions, extremely tight tolerances, and superior surface finishes. This precision is vital for optimal fitment, reduced play, minimized wear, and enhanced overall stability and safety of the assembled suspension system. It also facilitates easier field replacement of parts when necessary.

- Surface Treatment and Coating:

To provide robust protection against corrosion, which is a significant concern in the demanding automotive and transport environments, all steel components undergo advanced surface treatment. This often begins with thorough shot blasting to clean and prepare the metal surface, enhancing coating adhesion. Subsequently, components are typically coated using processes such as Electrophoretic Deposition (E-coating), which provides excellent uniform coverage and adhesion, followed by durable powder coating, or multi-layer liquid paint systems. These high-performance coatings offer exceptional resistance to rust, road salts, chemicals, and abrasive environments, significantly extending the product's lifespan and maintaining its aesthetic integrity, particularly crucial in industries like petrochemical transport or operations in coastal regions where corrosive elements are prevalent.

- Quality Control and Testing:

Throughout the entire manufacturing process, rigorous, multi-stage quality control checks are systematically implemented. This comprehensive testing regime ensures that every single Germany Type Suspension component meets the highest possible standards of performance, reliability, and safety. Key quality control measures include:

- Dimensional Inspections: Using precision tools like calipers, micrometers, height gauges, and sophisticated CMM (Coordinate Measuring Machines) for critical dimensional verification.

- Material Testing: In-house laboratories conduct continuous material testing, including hardness tests (Rockwell, Brinell, Vickers), tensile strength tests, yield strength tests, and Charpy impact tests on samples to confirm metallurgical integrity and mechanical properties.

- Weld Integrity Testing: Non-destructive testing (NDT) methods such as ultrasonic testing (UT), magnetic particle inspection (MPI), liquid penetrant inspection (LPI), and meticulous visual inspection are routinely performed on welded joints to ensure their structural integrity and freedom from defects.

- Fatigue Testing: Randomly selected finished leaf springs and complete suspension assemblies undergo dynamic fatigue testing on specialized hydraulic test rigs. These rigs simulate years of road stresses and millions of load cycles under controlled conditions to verify the design life, durability, and resistance to fatigue failure.

- Load Deflection Testing: Springs are subjected to precise load deflection tests to ensure they meet specified load capacities and spring rate characteristics.

- Coating Adhesion and Corrosion Resistance Tests: Adhesion tests (e.g., cross-hatch test) and salt spray tests are conducted to verify the quality and durability of the protective coatings.

Adherence to international quality management systems such as ISO 9001, ISO/TS 16949 (specifically for the automotive industry), and specific national standards like DIN (Deutsches Institut für Normung) or ANSI (American National Standards Institute) is maintained at every stage. This unwavering commitment to quality ensures that every Germany Type Suspension system delivered is of the highest possible standard.

Figure 1: Conceptual overview of Germany Type Suspension manufacturing stages, highlighting key processes from precise material preparation and heat treatment to final assembly and rigorous quality checks.

Product Materials and Their Significance:

- High-Strength Alloy Steels (e.g., SUP9, 60Si2Mn): These specialized alloys are indispensable for leaf springs. They are chosen for their superior elastic limit, high tensile strength, and remarkable fatigue resistance, enabling the springs to endure millions of compression and extension cycles without succumbing to permanent deformation or fatigue fracture. Their specific chemical composition ensures optimal response to heat treatment.

- High-Strength Low-Alloy (HSLA) Steels: Utilized for critical structural components like hangers, equalizer beams, and mounting brackets, HSLA steels provide an exceptional strength-to-weight ratio. This allows for reduced overall vehicle weight without compromising structural integrity or load-bearing capability. They also exhibit excellent weldability and formability, crucial for complex fabricated assemblies.

- Wear-Resistant Bushings (e.g., Polyurethane, Bronze): Employed at all critical pivot points within the suspension assembly (such as spring eyes, hanger pins, and equalizer beam pivots), these materials minimize friction, absorb vibrations, and resist abrasive wear. Polyurethane offers excellent resistance to abrasion, oils, and chemicals, while specialized bronze alloys provide high load-bearing capabilities with inherently low friction, significantly extending the service life of articulated joints and reducing noise.

- High-Grade Fasteners (e.g., Grade 8.8, 10.9 U-bolts): All fasteners, particularly U-bolts, are made from high-tensile strength steel, often classified as Grade 8.8 or 10.9. These bolts undergo specific heat treatment to ensure they possess the necessary strength and clamping force to securely fasten the suspension components, maintaining assembly integrity even under extreme dynamic loads and vibrations.

Applicable Industries and Advantages:

The inherent robustness, exceptional reliability, and performance consistency of Germany Type Suspension make it the ideal choice for a wide array of heavy-duty applications across diverse and demanding industries:

- Long-Haul Logistics & Transportation: For semi-trucks and trailers engaged in continuous long-distance freight operations, where consistent performance under varying load conditions and high mileage is critical. The system ensures stable cargo transport, reduced tire wear, and minimizes unscheduled downtime.

- Construction & Infrastructure: Essential for dump trucks, concrete mixers, heavy equipment transporters (e.g., for excavators, bulldozers, cranes), and lowboy trailers operating on rugged, uneven construction sites, often under maximum permissible loads. It provides the necessary strength and stability to navigate challenging terrains while protecting the vehicle and its cargo.

- Mining & Quarry Operations: Incredibly demanding environments where haul trucks and specialized heavy-duty vehicles transport immense loads of ore, rock, and overburden over highly abrasive and continuously uneven terrain. The extreme durability, high fatigue resistance, and superior anti-corrosion properties of Germany Type Suspension are critical for maintaining operational uptime and safety in these harsh conditions, resisting aggressive chemical environments and abrasive dust.

- Oil & Gas Exploration & Transport: For tankers and specialized trailers used in transporting fuels, chemicals, drilling equipment, and other hazardous materials, often across remote, unpaved roads and through extreme weather conditions. The inherent robustness and superior stability of the suspension system minimize the risk of accidents and ensure secure transport of potentially dangerous cargo. The advanced anti-corrosion treatments are vital for resisting corrosive petrochemicals and environmental elements, ensuring long-term structural integrity.

- Waste Management & Recycling: Refuse collection vehicles, waste compactors, and recycling trucks operate with frequent stops, starts, and often carry high-density, dynamically shifting loads. The Germany Type Suspension provides the essential load-bearing capability and durability to handle these demanding operational cycles while ensuring vehicle stability for safer maneuvering in congested urban environments.

- Port & Container Handling: Critical for terminal tractors and specialized trailers used in moving heavy shipping container111s within port facilities. These operations require continuous heavy lifting and precise maneuvering in confined spaces, demanding highly durable and stable suspension systems.

- Specialized Heavy Transport: For oversized or super-heavy loads, such as wind turbine components, large industrial modules, or bridge sections, custom-engineered multi-axle trailers equipped with robust Germany Type Suspension systems are paramount. These applications demand exceptional load capacity, precise load distribution, and ultimate reliability for safe transport of colossal structures.

In these challenging sectors, the Germany Type Suspension consistently excels due to its:

- Exceptional Load Capacity: Meticulously engineered to reliably handle the heaviest gross vehicle weights (GVW) without compromising structural integrity or long-term performance.

- Unmatched Durability and Long Service Life: Thanks to advanced materials and rigorous manufacturing processes (like heat treatment and shot peening), these systems boast a designed life often exceeding 500,000 km, leading to significantly reduced downtime and substantially lower operational costs over the vehicle's lifespan.

- Enhanced Vehicle Stability and Control: The inherently robust mechanical design provides superior vehicle stability, significantly reducing body roll and improving handling characteristics, which is particularly crucial for vehicles carrying high-center-of-gravity loads or traversing uneven terrain. This translates to safer operations.

- Optimized Tire Wear: By ensuring optimal and balanced load distribution across all axles, especially through the ingenious equalizer beam mechanism in multi-axle setups, the system minimizes uneven tire wear, thereby extending tire life and generating significant savings on tire replacement costs – a major operational expense for fleets.

- Reduced Maintenance Requirements: Being mechanically simpler than complex air suspension systems, the Germany Type Suspension has fewer potential points of failure, leading to less frequent and generally simpler, more cost-effective maintenance procedures and repairs. Robust components like long-life bushings further minimize routine servicing.

- Superior Corrosion Resistance: The application of high-quality, multi-layer protective coatings (e.g., E-coating, powder coating) makes the suspension components highly resistant to rust, chemical degradation, and environmental wear. This is especially vital in corrosive environments such as those found in petrochemical transport, coastal operations, or areas using heavy road salts, ensuring prolonged structural integrity and operational safety.

- Cost-Effectiveness (Total Cost of Ownership - TCO): While the initial investment might be marginally higher than some basic, less robust suspension systems, the extended lifespan, significantly reduced maintenance demands, and improved tire longevity collectively contribute to a dramatically lower Total Cost of Ownership over the vehicle's operational life, providing a strong return on investment.

Technical Advantages and Performance Superiority

The Germany Type Suspension offers a compelling suite of technical advantages that unequivocally position it as a superior choice for heavy-duty applications. Its design philosophy, rooted in decades of precision German engineering, emphasizes ruggedness, longevity, and operational efficiency, directly addressing and mitigating the common pain points often associated with less robust or more complex suspension systems.

Key Technical Differentiators:

- Unmatched Durability and Robustness: Built from high-grade alloy steels (such as SUP9 or 60Si2Mn) and subjected to meticulous heat treatment processes (quenching and tempering) followed by specialized surface hardening techniques like shot peening, these suspensions are engineered from the ground up to absorb massive dynamic shocks and distribute heavy static and dynamic loads evenly over incredibly extended periods. This inherent, built-in strength significantly reduces the risk of structural fatigue, stress-induced cracking, and premature failure, even under continuous, demanding heavy-duty cycles on rough terrains.

- Exceptional Load-Bearing Capacity: Designed specifically to reliably carry the heaviest payloads encountered in commercial transport, the multi-leaf spring configuration, meticulously engineered in conjunction with highly robust equalizer beams, ensures that the immense weight is effectively managed and distributed across all axles. This sophisticated load management prevents overloading on individual axles, extends the structural life of the vehicle chassis, and significantly enhances overall operational safety. A typical Germany Type Suspension system is capable of consistently handling axle loads ranging from 13 to 16 metric tons, with specialized configurations engineered for even higher capacities, far exceeding standard requirements for general cargo.

- Superior Vehicle Stability and Control: The inherently rigid and precisely engineered design of the Germany Type Suspension system minimizes undesirable vehicle body roll and excessive sway, particularly evident during high-speed cornering maneuvers, emergency braking, or when traversing severely uneven terrain. This enhanced stability is absolutely critical for maintaining complete control of heavy vehicles, substantially reducing the risk of dangerous rollovers, and ensuring safer transport of goods, especially those with a high center of gravity or sensitive cargo. This translates directly to improved driver confidence and reduced accident rates.

- Optimized Tire Wear and Extended Tire Life: The sophisticated equalizer beam mechanism, a hallmark of this suspension type, meticulously balances the load distribution between tandem or tridem axles. This precisely balanced load ensures that tires on all axles experience uniform contact pressure and uniform wear patterns. This dramatically extends the operational lifespan of expensive heavy-duty tires, leading to significant reductions in operational costs associated with frequent tire replacements. Furthermore, optimized tire wear contributes indirectly to better fuel efficiency by maintaining ideal rolling resistance and minimizing tire scrubbing.

- Significantly Reduced Maintenance Overhead: In stark contrast to complex air suspension systems that rely on an intricate network of pneumatic components, air lines, electronic sensors, and control modules, the Germany Type Suspension is fundamentally mechanically simpler. This inherent simplicity translates directly into significantly fewer potential points of failure, a lower frequency of required maintenance interventions, and often, much easier, more straightforward, and ultimately more cost-effective repairs when they do become necessary. Robust components, such as long-life wear-resistant bushings and self-lubricating pivot points, further contribute to minimal routine servicing requirements, maximizing vehicle uptime.

- Unparalleled Resilience in Harsh Operating Environments: Whether vehicles are operating in the extreme temperatures of arid deserts, the highly corrosive salt-laden air of coastal roads, the abrasive dust and debris of mining sites, or environments exposed to aggressive industrial chemicals, the high-quality materials and multi-layer protective coatings (e.g., advanced E-coating and durable powder coating) ensure that the Germany Type Suspension maintains its structural integrity and peak performance. This makes it exceptionally suitable for highly specialized industries such as petrochemical transport, where equipment is constantly exposed to aggressive chemical agents and widely varying climates. Its inherent anti-corrosion properties and prolonged structural integrity are critical for safety and sustained operation in such challenging conditions.

Comparison with Other Suspension Types:

To further elucidate its distinct advantages and value proposition, let's briefly compare the Germany Type Suspension with other commonly utilized heavy-duty suspension systems in the commercial vehicle market:

| Feature | Germany Type Suspension | American Type Suspension (e.g., Hutchens) | Air Suspension |

|---|---|---|---|

| Design Philosophy | Built for extreme loads, paramount durability, precise load distribution, and long service life. Focus on mechanical robustness. | Emphasizes cost-effectiveness, simplicity, and traditional leaf spring design for general freight applications. | Prioritizes ride comfort, superior cargo protection, adjustable ride height, and electronic load leveling. |

| System Complexity | Medium (entirely mechanical, robust construction, minimal electronic components). | Low (basic mechanical leaf spring system, very straightforward components). | High (involves complex pneumatic components, air lines, electronic control units, height sensors, and sophisticated air bags). |

| Load Capacity (per axle) | Exceptional (consistently up to 16+ metric tons/axle or higher for specialized designs). Designed for peak heavy haul. | Good (typically up to 12.5 metric tons/axle). Adequate for standard heavy freight. | Good (load capacity can be electronically adjusted, but complex for maximum static and dynamic loads without additional reinforcement). |

| Ride Comfort | Good (due to multi-leaf spring design and the load-equalizing effect of the equalizer beam, providing a relatively smooth ride for a mechanical system). | Moderate (generally a stiffer and less forgiving ride, especially when unloaded, due to simpler leaf spring configurations). | Excellent (air bags effectively absorb road shocks and vibrations, providing the smoothest ride quality, ideal for sensitive cargo or passenger comfort). |

| Durability/Lifespan | Exceptional (designed for extended lifespan with high fatigue resistance and minimal wear, thanks to advanced materials and processes). | Good (robust by design, but simpler designs might have more localized stress points leading to wear in specific components). | Good (components are durable, but potential issues like air leaks in bags or lines, and sensor failures, can affect longevity and reliability). |

| Maintenance Cost | Low (fewer complex parts, simpler mechanical structure, and longer service intervals due to inherent durability lead to reduced costs). | Low (straightforward design means easy diagnosis and relatively inexpensive replacement of leaf springs). | High (complexity of the pneumatic and electronic system, higher cost of specialized parts, and need for diagnostic tools). |

| Initial Cost | Medium to High (reflects the investment in high-grade materials, precision manufacturing, and rigorous testing). | Low to Medium (due to simpler design and less complex manufacturing processes). | High (attributed to the advanced components, air compressor systems, and electronic control units). |

| Application Suitability | Optimal for extreme heavy haulage, highly challenging rough terrain operations, continuous long-distance transport, and high-stress industrial applications. | Best suited for general freight, regional transport, and applications where initial cost-effectiveness is a primary concern. | Ideal for transporting fragile or sensitive cargo, livestock, luxury coaches, and applications requiring precise height adjustment for loading/unloading (e.g., dock leveling). |

| Load Distribution | Superior (the equalizer beam ensures highly efficient and precise load balancing between multiple axles, optimizing tire contact). | Good (basic equalizer mechanisms provide load sharing, but often less refined than Germany Type). | Excellent (electronic load leveling systems provide dynamic and precise load distribution, reacting to changing conditions). |

As evident from this detailed comparison, while air suspensions offer unparalleled ride comfort and American type suspensions might present a lower initial upfront cost, the Germany Type Suspension strikes an optimal and compelling balance. It unequivocally prioritizes maximum load capacity, unparalleled durability, and significantly reduced long-term operational costs – these factors are absolutely paramount and non-negotiable for heavy-duty commercial vehicle operators who demand peak performance and reliability from their fleet assets.

Diverse Application Scenarios and Proven Advantages

The inherent versatility, formidable strength, and unwavering reliability of Germany Type Suspension systems make them an indispensable asset across a wide spectrum of demanding industries globally. Their proven ability to perform consistently and exceptionally under varying loads, across diverse terrains, and in the most challenging environmental conditions emphatically underscores their significant value proposition and strategic importance for heavy-duty transport operators.

Typical Application Contexts:

- Long-Haul Freight & Logistics: In the critical backbone of the global economy, long-haul trucking, trailers meticulously equipped with Germany Type Suspension ensure the safe, stable, and efficient transport of a vast array of goods across immense distances. The precisely balanced load distribution, facilitated by the equalizer beam, minimizes undue stress on both the vehicle chassis and the transported cargo, directly contributing to fewer breakdowns, reduced cargo damage, and consistently improved delivery timelines. The measurable reduction in tire wear is a significant and tangible cost-saving benefit for large fleets that accumulate hundreds of thousands of kilometers annually.

- Construction & Infrastructure Projects: Dump trucks, lowboy trailers meticulously designed for transporting massive excavators, towering cranes, and other heavy construction machinery rely absolutely on robust, high-capacity suspension systems. Whether navigating treacherous unpaved construction sites, ascending or descending steep gradients, or traversing public roads, the Germany Type Suspension provides the indispensable stability, superior load support, and impact absorption capabilities required. Its exceptional ability to absorb significant impacts from highly uneven surfaces powerfully protects the vehicle's structural integrity and substantially extends the operational life of other critical components.

- Mining & Quarry Operations: These environments are arguably among the harshest and most demanding for vehicle components. Haul trucks and specialized trailers operating in mines are continuously subjected to immense, often dynamic, loads (e.g., ore, rock, overburden) and continuous, severe vibrations over highly abrasive, continuously uneven, and often treacherous terrain. The inherent robust construction, exceptional load capacity, and superior fatigue resistance of Germany Type Suspension are absolutely critical for maintaining continuous operational uptime and ensuring the highest levels of safety in these relentlessly challenging conditions. Furthermore, its advanced anti-corrosion treatment plays a vital role in resisting the aggressive chemical environments and highly abrasive dust frequently encountered in mining operations.

- Oil & Gas Exploration & Transport: The transportation of sensitive drilling equipment, lengthy pipelines, and hazardous materials within the oil and gas sector frequently involves navigating extremely remote, often unpaved roads, and enduring highly unpredictable, extreme weather conditions. Tankers carrying volatile flammable liquids or pressurized gas cylinders demand unparalleled stability and the highest levels of safety. The inherent robustness, predictable handling characteristics, and superior stability of Germany Type Suspension systems critically minimize the risk of dangerous accidents and ensure the secure transport of critical, often dangerous, cargo, even in the most challenging geographical regions. The advanced anti-corrosion properties ensure that the suspension components can consistently withstand prolonged exposure to corrosive petrochemicals and harsh environmental elements, guaranteeing long-term structural integrity and sustained operational safety.

- Waste Management & Recycling: Refuse collection vehicles, waste compactors, and recycling trucks typically operate in demanding urban environments characterized by frequent stop-and-go cycles and the continuous handling of high-density, dynamically shifting loads. The Germany Type Suspension provides the essential, robust load-bearing capability and unwavering durability to handle these demanding operational cycles without compromise, while simultaneously ensuring optimal vehicle stability for safer and more precise maneuvering in often congested urban areas.

- Specialized Heavy Transport (e.g., Wind Turbines, Industrial Modules): For the transportation of exceptionally oversized or super-heavy loads, such as massive wind turbine blades, large industrial plant modules, or extensive bridge sections, custom-engineered trailers meticulously equipped with multi-axle Germany Type Suspension systems are absolutely paramount. These highly specialized applications demand unparalleled load distribution precision, unwavering stability, and ultimate, unwavering reliability to safely transport colossal, high-value structures across vast distances and challenging routes.

Figure 2: A heavy-duty trailer, meticulously equipped with Germany Type Suspension, confidently navigating a challenging industrial environment, powerfully demonstrating its robust and reliable application capabilities under demanding conditions.

Demonstrated Advantages in Real-World Scenarios:

- Enhanced Safety Margins: The superior stability, predictable handling characteristics, and robust load management capabilities significantly reduce the likelihood of dangerous rollovers or loss of vehicle control, particularly when carrying high, unstable, or dynamically shifting loads. This directly translates to substantially improved driver safety and a measurable reduction in accident rates, which is a critical metric for fleet insurance premiums and overall operational risk management.

- Substantial Reduction in Operational Costs: Beyond the documented benefits of extended tire life, the inherent durability and longevity of Germany Type Suspension components mean significantly fewer unscheduled repairs and dramatically reduced vehicle downtime. This directly translates into higher average vehicle utilization rates, lower labor costs associated with maintenance interventions, and a substantial reduction in expenditure on replacement parts, boosting overall fleet profitability.

- Extended Longevity of Vehicle Components: By highly effectively absorbing road shocks, dampening vibrations, and distributing immense loads uniformly, the robust suspension system significantly reduces stress, fatigue, and wear on other critical vehicle components. This includes the chassis, the main structural frame, the drivetrain, and even the braking system. This "protective effect" extends the overall operational lifespan of the entire vehicle fleet, effectively delaying the need for costly vehicle replacements and major overhauls.

- Unrivalled Suitability for Extreme Environments: The inherently robust construction, coupled with advanced anti-corrosion and protective treatments, ensures consistently reliable performance even in the most punishing environments. This includes regions exposed to pervasive salt (from coastal air or road de-icing), aggressive industrial chemicals (as commonly found in the petrochemical industry), extreme temperature fluctuations, or highly abrasive materials (like sand, dust, or mining particulates). This resilience ensures the long-term structural integrity and unwavering operational reliability of the suspension, actively preventing issues like premature material fatigue or rust-related failures that could otherwise lead to costly repairs or critical safety hazards.

- Indirect Contribution to Energy Efficiency: By consistently maintaining optimal vehicle geometry and precisely minimizing tire scrub (which is caused by uneven load distribution or misalignment), the Germany Type Suspension system contributes indirectly but measurably to improved fuel efficiency. Properly maintained suspensions ensure that tires maintain an ideal and consistent contact patch with the road surface, thereby reducing rolling resistance and maximizing fuel economy over long hauls.

These tangible, real-world benefits collectively highlight why the Germany Type Suspension is not merely a conventional component, but a highly strategic and invaluable investment for any business operating heavy-duty vehicles. It consistently delivers significant and measurable returns through vastly enhanced safety, substantially reduced operational costs, and a significantly extended operational life for the entire vehicle fleet.

Choosing Your Partner: Manufacturer Comparison and Customization Solutions

Selecting the right manufacturer and supplier for Germany Type Suspension systems is as fundamentally crucial as understanding the technical merits of the product itself. The global market offers a multitude of suppliers, but discerning true quality, unwavering reliability, and robust support is absolutely paramount for achieving long-term operational success and maximizing your fleet's investment. This comprehensive section meticulously outlines key considerations for conducting a thorough manufacturer comparison and highlights the significant potential for highly customized suspension solutions tailored to unique operational demands.

Key Factors for Manufacturer Comparison:

- Extensive Experience and Unblemished Reputation: Prioritize manufacturers with a long-standing, proven history in the heavy-duty vehicle component industry and an unblemished reputation for delivering consistent quality, unwavering reliability, and exceptional customer service. A track record spanning over two decades, for instance, typically signifies deep accumulated expertise, refined designs, and robust manufacturing processes. Look for positive client testimonials, industry awards, and a strong market presence as indicators of reputability.

- Adherence to Certifications and Stringent Quality Standards: It is imperative to verify that the manufacturer rigorously adheres to and holds certifications for international quality management systems, most notably ISO 9001:2015. Furthermore, for the automotive sector, look for specific industry certifications like IATF 16949, which denotes a highly specialized quality management system for automotive suppliers. Adherence to regional and material-specific standards such as DIN (Deutsches Institut für Normung), JIS (Japanese Industrial Standards), or ASTM (American Society for Testing and Materials) for raw materials, design, and testing processes further provides irrefutable assurance of consistent product quality and reliable performance. These certifications are not mere badges; they represent a deep, systematic commitment to meticulous quality control, continuous process improvement, and adherence to global best practices.

- Robust Research & Development (R&D) Capabilities: A truly forward-thinking and innovative manufacturer consistently invests substantially in R&D to continuously refine, innovate, and improve their product offerings. Inquire about the size and expertise of their engineering and metallurgical teams, the presence of in-house advanced testing facilities, and how they actively integrate cutting-edge materials science or novel design principles into their product lines. A strong R&D focus is a clear indicator of a manufacturer's capacity to adapt swiftly to evolving industry needs, anticipate future demands, and deliver truly cutting-edge, high-performance suspension solutions.

- Advanced Manufacturing Technology and Precision: Critically assess their manufacturing processes. Do they utilize state-of-the-art technologies such as fully automated robotic welding for superior weld integrity, high-precision CNC machining for tight tolerances, computer-controlled automated heat treatment furnaces for metallurgical consistency, and precise shot peening equipment for enhanced fatigue life? A strong emphasis on automation, advanced robotics, and precision tooling directly translates into significantly higher product consistency, superior reliability, and reduced variability in performance. Request detailed process descriptions or virtual factory tours to gain insight into their operational excellence.

- Transparent Material Sourcing and Full Traceability: Gain a clear understanding of where their raw materials originate. Reputable manufacturers will invariably source their materials from only the most certified and globally recognized mills and maintain complete, end-to-end traceability of every batch of material used. This meticulous traceability ensures the unequivocal integrity, purity, and quality of the high-strength steels and alloys incorporated into their suspension components, which is absolutely crucial for guaranteed performance and uncompromised safety.

- Comprehensive After-Sales Support and Strong Warranty: A robust, clearly defined warranty (e.g., typically ranging from 1 to 2 years or specified mileage, whichever comes first) and comprehensive after-sales support (including dedicated technical assistance, readily available spare parts inventory, and an established global service network) are absolutely vital for long-term peace of mind. A generous warranty demonstrates the manufacturer's profound confidence in the durability and reliability of their product and their unwavering commitment to ultimate customer satisfaction. The prompt and guaranteed availability of genuine spare parts is paramount for minimizing costly vehicle downtime and ensuring continuous operation.

- Impressive Client Portfolio and Proven Case Studies: Review their existing client base. Do they supply major global vehicle OEMs (Original Equipment Manufacturers) or large, reputable fleet operators with exacting standards? Detailed and successful case studies, coupled with consistently positive client feedback, provide tangible and verifiable evidence of their product's real-world performance and their unwavering commitment to service quality. This validates their authority and trustworthiness in the market.

- Commitment to Environmental and Sustainability Practices: In today's conscientious market, manufacturers are increasingly evaluated on their environmental stewardship and sustainability initiatives. Look for clear commitments to sustainable manufacturing processes, proactive waste reduction programs, energy-efficient operations, and responsible material sourcing. This reflects a broader commitment to ethical business practices and long-term viability.

The Power of Customized Solutions:

While standard, off-the-shelf Germany Type Suspension models already offer robust and reliable performance, a significant number of heavy-duty transport applications present unique operational requirements that necessitate bespoke, highly tailored customization. Leading and reputable manufacturers deeply understand this critical need and actively offer comprehensive customized solutions to meticulously optimize suspension performance for specific and often highly specialized operational contexts.

Customization possibilities for Germany Type Suspension systems can involve, but are not limited to:

- Specific Axle Configurations and Spacing: Tailoring the number, arrangement, or precise spacing of axles for highly specialized trailers (e.g., multi-axle modular transporters for abnormal loads) or adjusting the wheelbase dimensions to meet stringent specific vehicle dimensions or complex regional regulatory compliance requirements.

- Precise Load Rating Adjustments: Engineering specific leaf spring packs and equalizer beams to reliably handle higher or lower specific dynamic and static loads than standard catalogue offerings. This often necessitates precise changes in material thickness, the exact number of leaves within a spring pack, or the cross-sectional geometry of the equalizer beam and hangers.

- Optimized Mounting Height and Custom Ride Height: Adjusting the suspension geometry, including hanger designs and spring seat positions, to achieve a very specific vehicle overall height. This can be crucial for unique loading/unloading requirements (e.g., self-loading trailers), for achieving optimal aerodynamic profiles, or for meeting specific bridge clearance limitations.

- Enhanced Material Specifications and Bespoke Surface Treatments: Utilizing specialized high-performance alloys or applying highly specific, advanced surface treatments for operations in extreme environmental conditions. This includes, for instance, highly enhanced anti-corrosion coatings for continuous exposure in maritime environments (saltwater spray), or the application of specialized abrasion-resistant materials for continuous operation in highly dusty, sandy, or muddy conditions (e.g., mining or desert operations). For highly specialized industries like chemical transport, bespoke protective coatings are engineered to be resistant to a significantly wider range of aggressive chemicals, going far beyond standard anti-corrosion treatments to ensure long-term structural integrity, product containment, and uncompromising safety.

- Seamless Integration with Other Vehicle Systems: Designing the suspension system to seamlessly integrate and function optimally with specific braking systems, advanced steering mechanisms (e.g., forced steering axles), or highly specialized chassis designs. This ensures perfect system compatibility, preventing interference, and maximizing overall vehicle performance and safety.

- Bespoke Equalizer Beam Designs: For highly specialized multi-axle setups, or for applications that frequently traverse extremely uneven or undulating terrain, the geometry, length, and pivot points of the equalizer beam might be precisely modified to achieve truly optimal load distribution, maximum articulation, and superior off-road capability.

The customization process typically involves a highly collaborative and iterative approach between the client's engineering and operational teams and the manufacturer's dedicated R&D and design departments. It commences with an in-depth, detailed analysis of the client's precise operational requirements, comprehensive load profiles (static and dynamic), prevailing environmental conditions, and all relevant regulatory compliance mandates. This meticulous analysis then forms the basis for a conceptual design, which progresses into detailed engineering, advanced Finite Element Analysis (FEA) to rigorously simulate stresses, strains, and performance under various conditions, followed by rapid prototyping, and culminating in a series of rigorous physical tests. This deeply collaborative and technically driven approach ensures that the resulting Germany Type Suspension system is not just merely suitable, but is perfectly tailored and meticulously optimized to the client's unique and demanding needs, thereby maximizing operational efficiency, ensuring unparalleled safety, and delivering a superior return on investment.

Application Case Studies and Client Trust

The true and ultimate measure of a product's excellence, superior quality, and enduring reliability lies unequivocally in its real-world performance under operational conditions and the profound level of trust it consistently garners from its discerning users. Germany Type Suspension systems have consistently and demonstrably proven their exceptional reliability, remarkable efficiency, and superior performance across a multitude of challenging and diverse applications worldwide, leading to overwhelmingly positive feedback, strong testimonials, and a high rate of repeat business from a growing base of highly satisfied clients. These case studies underscore the practical benefits and the strategic advantage of choosing a Germany Type Suspension.

Illustrative Application Cases:

Case Study 1: Heavy Machinery Transport in the Rocky Mountains

A prominent North American construction and mining logistics company, specializing in the demanding transport of oversized and super-heavy equipment, faced persistent and significant issues with premature suspension wear, frequent component failures, and accelerated tire degradation on their conventional trailers. These problems became particularly acute when moving massive excavators, formidable bulldozers, and other heavy plant machinery through the steep, undulating, and often unpaved mountainous terrain of the Rocky Mountains. The relentless combination of severe gradients, sharp turns, and highly uneven road surfaces placed immense and unsustainable dynamic stresses on their existing suspension systems, leading to critically frequent vehicle downtime for repairs and substantial, recurring operational costs in terms of tire replacements and component procurement. This significantly impacted their project timelines and profitability.

Upon a strategic transition of a significant portion of their heavy-haul fleet to trailers meticulously equipped with Germany Type Suspension, specifically designed for tandem and tridem axle configurations with robust, enhanced multi-leaf spring packs, they observed a truly dramatic and immediate improvement in overall fleet performance and operational metrics. The robust, precision-engineered equalizer beam mechanism consistently ensured optimal and balanced load distribution across all axles, even when traversing exceptionally steep grades, highly uneven surfaces, and complex off-road conditions. Within a remarkable 18 months of continuous operation under these demanding conditions, the fleet reported an impressive increase in tire life by over 25%, and critically, unscheduled suspension-related maintenance interventions were reduced by a staggering 40%. Furthermore, their professional drivers consistently reported significantly improved vehicle stability, enhanced directional control, and a more comfortable ride, which profoundly enhanced safety during critical maneuvers on treacherous mountain roads and contributed to reduced driver fatigue. This unequivocally positive experience led to a strategic, phased replacement of their entire heavy-haul fleet with trailers exclusively featuring Germany Type Suspension systems, solidifying a long-term partnership with the supplier.

Case Study 2: Chemical Tanker Fleet Operating in a Highly Corrosive Coastal Region

A leading chemical logistics company, operating an extensive fleet of specialized tankers along a highly corrosive coastal route in a hot, humid region of the Middle East, struggled intensely with the pervasive and rapid corrosion of their existing suspension components. This relentless environmental degradation led to severe structural integrity issues, frequent material failures, and significant safety concerns due to the compromise of critical load-bearing elements. The constant exposure to concentrated saltwater spray, high humidity, and extreme ambient temperatures necessitated incredibly frequent, costly maintenance, extensive component refurbishment, and premature, expensive replacement of entire suspension parts, severely impacting their operational budget and fleet availability.

In response to these critical challenges, they strategically adopted Germany Type Suspension systems, which featured advanced, multi-layer anti-corrosion coatings. These specialized protective layers included robust electrophoretic deposition (E-coating) as a base layer, followed by a highly specialized topcoat explicitly formulated for superior resistance to aggressive chlorides and other corrosive chemical agents prevalent in their operating environment. The inherent robust design of the Germany Type Suspension, synergistically coupled with these superior protective surface layers, drastically improved component longevity and maintained structural integrity. After a rigorous two years of continuous operation under these extreme conditions, visual inspections consistently showed only minimal, superficial signs of corrosion, and critically, there were no reported structural failures or operational issues directly attributable to material degradation. This profound improvement not only dramatically enhanced the safety of their hazardous material transport operations but also resulted in a significant reduction in their annual maintenance budget for suspension systems, estimated at over 30%, emphatically affirming the immense value of the specialized material treatments and protective coatings integrated into the Germany Type Suspension manufacturing process.

Case Study 3: High-Volume Logistics Fleet in Central Europe

A major pan-European logistics provider, with an unwavering commitment to optimizing their extensive trailer fleet for maximum efficiency, reduced total cost of ownership (TCO), and improved operational uptime, conducted a rigorous comparative analysis of various heavy-duty suspension types available in the market. Their existing trailer fleet, which was primarily fitted with basic, conventional mechanical suspensions, was experiencing higher-than-desired rates of tire wear, leading to inflated operational costs, and alarmingly, occasional leaf spring breakages due to the unrelenting intensity of continuous, high-speed, long-distance freight operations across diverse European road networks.

Through a strategic decision to integrate new trailers equipped with Germany Type Suspension, they were able to fully capitalize on its well-documented and proven benefits. The meticulous precision in load distribution, inherent to the design, ensured optimal and consistent tire contact with the road surface, leading to a measurable and significant increase in tire mileage across their entire fleet. Furthermore, the enhanced fatigue resistance of the meticulously heat-treated and shot-peened leaf springs virtually eliminated the previously problematic leaf spring breakages, which dramatically reduced unscheduled repairs and associated downtime. This pivotal improvement allowed them to measurably increase their fleet's overall operational efficiency by an impressive 5%, directly contributing to higher profit margins and a stronger competitive position in the logistics market. The overwhelmingly positive experience and quantifiable returns on investment cultivated a strong, long-term strategic partnership with the Germany Type Suspension manufacturer for all their subsequent new trailer procurements and fleet upgrades, underscoring the system's economic advantages.

Client Feedback and Trust Building:

The recurring and consistent themes emerging from extensive client feedback regarding Germany Type Suspension systems universally include:

- "Unmatched Reliability in Operation": Operators consistently and emphatically praise the system's unwavering ability to perform flawlessly without failure, even under the most strenuous and punishing operational conditions, day in and day out.

- "Significant and Measurable Cost Savings": The tangible benefits of measurably reduced tire wear, substantially lower maintenance frequencies, and significantly extended component life directly translate into profound and sustainable long-term financial savings for fleet operators.

- "Profoundly Enhanced Safety": Professional drivers, safety managers, and fleet owners alike universally appreciate the remarkable improvements in vehicle stability, predictable handling characteristics, and enhanced control, particularly when navigating challenging road conditions or transporting sensitive, high-value, or hazardous cargo.

- "Exceptional and Enduring Durability": The system's unparalleled ability to consistently withstand a wide array of harsh environmental factors and continuously manage immense heavy loads without compromise is a frequently highlighted and deeply valued attribute by operators.

- "Highly Responsive and Comprehensive Support": Manufacturers that supply Germany Type Suspension are consistently commended by their clients for their highly responsive technical support, guaranteed spare parts availability, proactive maintenance guidance, and their unwavering willingness to offer highly customized solutions tailored to specific client needs, fostering long-term relationships built on trust.

These compelling real-world experiences and consistently positive testimonials robustly reinforce the inherent credibility and profound trustworthiness of Germany Type Suspension systems. They firmly position these systems not merely as a component purchase, but as a crucial and strategic asset for any heavy-duty transport operation seeking to definitively optimize operational performance, systematically minimize recurring costs, and uncompromisingly prioritize the safety and longevity of their valuable vehicle fleet assets.

Professional FAQ (FAQ) on Germany Type Suspension

To provide a deeper and more nuanced understanding of Germany Type Suspension systems and to comprehensively address common inquiries from industry professionals, fleet managers, and potential users, here are detailed answers to frequently asked questions regarding their materials, specifications, installation standards, and operational benefits:

-

What is the primary material used for the leaf springs in Germany Type Suspension, and why is it chosen?

The primary material specifically used for the leaf springs in Germany Type Suspension systems is high-grade alloy steel, typically specified according to international standards as SUP9, 60Si2Mn (Chinese GB standard), or 50CrVA (US/European equivalents). These specialized materials are meticulously chosen for their superior combination of properties: exceptional elasticity (the ability to deform under load and return to original shape), very high tensile strength (resistance to breaking under tension), and outstanding fatigue resistance (the ability to withstand millions of load cycles without developing cracks or permanent deformation). These properties are absolutely crucial for the spring's long-term performance and reliability in heavy-duty applications, ensuring it can absorb immense road shocks and bear heavy loads consistently over its entire service life.

-

How does the equalizer beam in Germany Type Suspension significantly enhance overall vehicle performance and tire longevity?

The equalizer beam (also colloquially known as a rocker arm) is an absolutely critical, intelligent mechanical component, especially in multi-axle configurations such as tandem or tridem setups within the Germany Type Suspension system. Its primary, indispensable function is to dynamically and evenly distribute the load between adjacent axles. As one wheel or axle encounters an obstacle (e.g., a pothole or bump) or a dip in the road, the equalizer beam precisely pivots, instantaneously transferring a portion of the load to the adjacent axle. This mechanism ensures that each axle consistently bears a proportionate share of the vehicle's total weight, thereby preventing localized overloading on any single axle, significantly minimizing uneven and premature tire wear, and dramatically improving overall vehicle stability and traction, particularly when traversing highly uneven, undulating, or challenging terrain. This balanced load distribution directly contributes to extended tire life and enhanced operational safety.

-

What are the typical load capacity ranges that Germany Type Suspension systems are designed to handle?

While specific maximum load capacities can indeed vary based on the precise model, the specific configuration (e.g., number of leaf springs, spring thickness, axle type), and the intended application, Germany Type Suspension systems are generally robustly designed for the most demanding heavy-duty transport applications. A single axle equipped with this type of suspension can typically and reliably handle dynamic loads ranging from approximately 13,000 kg (equivalent to around 28,660 lbs) to 16,000 kg (approximately 35,270 lbs). For multi-axle setups, such as tandem or tridem configurations, the total permissible load capacity of the suspension system increases proportionally, making them exceptionally well-suited for the heaviest and most challenging transport requirements encountered globally.

-

Which specific manufacturing processes are most crucial for ensuring the superior durability and longevity of Germany Type Suspension?

Several critical manufacturing processes are absolutely instrumental in ensuring the superior durability, resilience, and extended longevity of Germany Type Suspension systems. These include: Precision Heat Treatment (comprising meticulous quenching and controlled tempering), which precisely optimizes the steel's microstructure for maximum strength, toughness, and fatigue resistance; Advanced Shot Peening, which induces beneficial compressive residual stresses on the surface of leaf springs, dramatically enhancing their fatigue life and preventing crack initiation; Automated Robotic Welding, which guarantees consistently high-strength, precise, and structurally sound joints for all fabricated structural components; and High-Precision CNC Machining, which ensures exact dimensions, extremely tight tolerances, and superior surface finishes for optimal fitment, reduced wear, and improved overall system integrity. Furthermore, the application of multi-layer, high-performance Anti-Corrosion Coatings provides essential protection against environmental degradation, significantly extending the operational life of components exposed to harsh conditions.

-

Can Germany Type Suspension be effectively customized for highly specialized vehicle applications or unique operational needs?

Absolutely. Leading manufacturers of Germany Type Suspension systems offer extensive and highly flexible customization options to meet the precise requirements of highly specialized vehicle applications and unique operational needs. This comprehensive customization can include, but is not limited to, adjusting specific axle configurations (e.g., altering the number of axles, modifying inter-axle spacing), precisely tailoring load ratings to accommodate bespoke payload demands, optimizing mounting heights or overall ride heights for specific operational clearances or loading requirements, selecting highly specialized materials or applying advanced protective coatings for extreme environmental exposure (e.g., enhanced chemical resistance for petrochemical transport or superior abrasion resistance for mining environments), and ensuring seamless integration with unique chassis designs, braking systems, or steering mechanisms. This bespoke engineering approach guarantees optimal performance, safety, and compatibility for highly specialized heavy-duty transport requirements.

-

What international quality and performance standards does Germany Type Suspension typically adhere to during its manufacturing?

Germany Type Suspension systems are meticulously manufactured to strictly adhere to a rigorous set of international quality management systems and specific performance standards, reflecting a commitment to global excellence. These commonly include, but are not limited to: ISO 9001 (the globally recognized standard for Quality Management Systems), and often IATF 16949 (the highly specialized quality management system standard developed specifically for the automotive industry, which emphasizes continuous improvement, defect prevention, and reduction of variation and waste in the supply chain). Additionally, specific product design, material composition, and testing standards from recognized bodies such as DIN (Deutsches Institut für Normung - German Institute for Standardization), JIS (Japanese Industrial Standards), or ASTM (American Society for Testing and Materials) are meticulously followed to ensure the highest level of material integrity, structural compliance, and consistent product reliability across all manufactured batches.

-

How does the Germany Type Suspension specifically contribute to reduced tire wear and improved fuel efficiency?

The Germany Type Suspension significantly contributes to reduced tire wear primarily through its robust and intelligently designed equalizer beam mechanism, particularly in multi-axle configurations. This beam ensures that the load is precisely and evenly distributed across all axles, preventing any single axle or tire from being overloaded or subjected to uneven stress. This balanced load distribution critically minimizes tire scrubbing and the formation of irregular wear patterns, thereby directly extending the operational lifespan of expensive heavy-duty tires and substantially reducing replacement costs for fleet operators. Indirectly, by maintaining optimal vehicle geometry and ensuring consistent, even contact between the tires and the road surface, the suspension system helps to minimize rolling resistance, which, in turn, contributes to a noticeable improvement in overall fuel efficiency, a critical economic factor for heavy vehicle fleets.

Procurement, Quality Assurance, and Customer Support

Investing in Germany Type Suspension is a strategic and often substantial decision for heavy-duty fleet operators. Therefore, having a clear understanding of the procurement process, the unwavering quality commitments, and the comprehensive scope of available customer support is absolutely essential for ensuring a seamless acquisition experience and guaranteeing long-term operational success, maximizing the return on your investment in these robust systems.

Delivery Cycle and Logistics:

The precise delivery cycle for Germany Type Suspension components can naturally vary based on a multitude of factors, including the specific order volume, the degree of customization required for the suspension system, and the manufacturer's current production schedules and backlog. Typically, for standard configurations and readily available models, lead times might range from approximately 4 to 8 weeks. This timeframe accounts for the complete manufacturing process, rigorous multi-stage quality control checks, and the necessary logistics preparation for shipment. For highly customized solutions, where bespoke engineering, specialized material sourcing, or extensive prototyping might be involved, this lead period can extend accordingly. Reputable manufacturers leverage highly efficient, globally integrated supply chain management systems and extensive distribution networks to ensure timely and reliable delivery worldwide. They often provide clients with detailed, transparent shipping schedules and real-time tracking information to maintain full visibility throughout the logistics process. Furthermore, they collaborate closely with experienced logistics partners to ensure the safe, secure, and most efficient transport to destinations across the globe, whether via cost-effective sea freight for bulk orders or expedited air cargo for urgent, time-sensitive requirements.

Quality Assurance & Unwavering Warranty Commitment:

Manufacturers of Germany Type Suspension systems stand firmly behind the superior quality and inherent reliability of their products through exceptionally comprehensive quality assurance protocols and robust, clearly defined warranty policies. The rigorous quality assurance process commences at the very initial stage, with the meticulous selection and verification of raw materials, and extends continuously through every single stage of the manufacturing process – encompassing precision cutting, advanced forming, specialized heat treatment, automated welding, high-precision machining, and protective coating applications. This meticulous oversight culminates in stringent final inspections and exhaustive performance testing for every completed unit. Each and every component is subjected to a battery of rigorous quality checks to ensure unwavering compliance with specified dimensions, confirmed material properties, and guaranteed load-bearing capacities. Advanced fatigue testing, often simulating years of extreme operational stress under controlled laboratory conditions, is a standard and critical procedure employed to unequivocally validate the design life, long-term durability, and resilience against material fatigue.