Lis . 06, 2024 23:03 Back to list

drawbar repair products

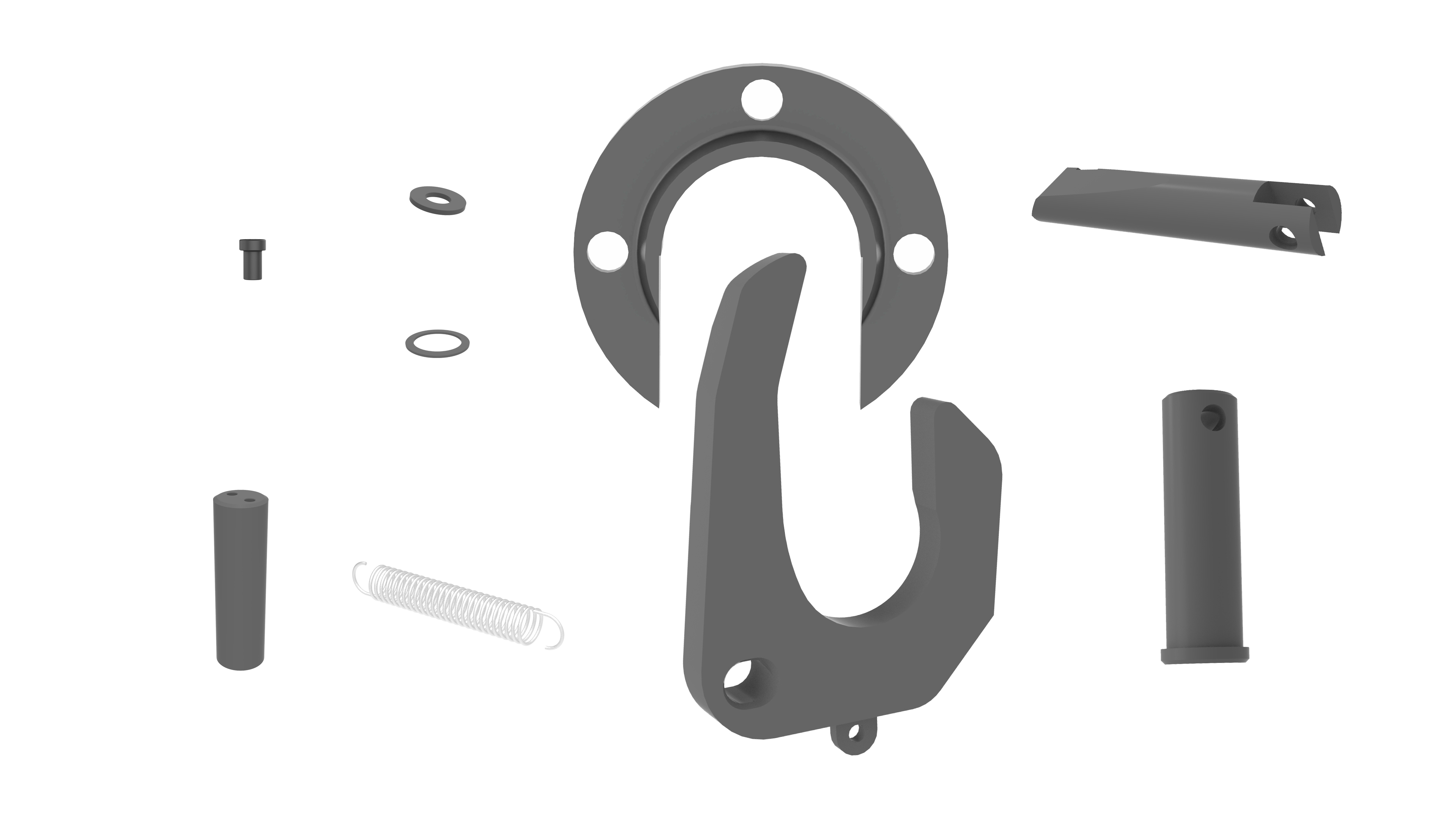

Understanding Drawbar Repair Products A Comprehensive Guide

When it comes to heavy machinery and vehicle towing systems, the drawbar is an essential component. It connects different vehicles, ensuring safe and efficient transport. However, like any part of a machine, drawbars can suffer wear and tear, leading to the need for repair or replacement. This is where drawbar repair products come into play, offering solutions to maintain safety and functionality.

Drawbar repair products are specifically designed to address issues such as cracks, wear, and corrosion in drawbars. These problems can arise from the constant stress and load during towing operations. To effectively restore a drawbar, several repair products are available, each suitable for particular types of damage.

One of the most common repair solutions is the use of epoxy adhesives. These versatile products can bond metallic surfaces, filling in cracks and preventing further damage. When selecting an epoxy, it is crucial to choose one formulated for metal repairs, ensuring it can withstand the forces exerted during towing. Proper surface preparation is essential; the area should be thoroughly cleaned and prepped to ensure optimal adhesion.

drawbar repair products

Another useful product for drawbar repair is metal fillers. These are often used to restore the shape and integrity of the drawbar after significant wear. Metal fillers can be shaped, sanded, and painted once cured, making them an excellent choice for a seamless repair. They can also be used in combination with other repair products to enhance durability.

Welding is another traditional method for drawbar repair. It involves joining materials using heat, providing a robust solution for structural issues. However, welding requires skilled labor and the right equipment. If carried out incorrectly, it could lead to further damage or weakened structural integrity. Therefore, it is crucial to assess whether welding is the right choice for your specific situation.

In addition to these methods, various protective coatings and rust inhibitors can help prolong the life of a drawbar. Applying a protective layer can prevent corrosion and wear, reducing the frequency of repairs. Many manufacturers offer specialized coatings designed to resist the harsh conditions drawbars endure.

In conclusion, maintaining the functionality and safety of drawbars is essential in heavy machinery and towing operations. Utilizing drawbar repair products, such as epoxy adhesives, metal fillers, and protective coatings, can ensure that drawbar components remain in optimal condition. Regular inspection and timely repairs not only enhance safety but also extend the service life of your equipment, ensuring efficient operations for years to come. Always consult with professionals or follow manufacturer guidelines when performing repairs to achieve the best results.

-

Nuss Truck Sauk Rapids - High Quality, Best Deals & Discounts Available

NewsJul.08,2025

-

High Quality Kingpin Adalah – Best Kingpin Adalah for Trucks, Get Discount Kingpin Adalah Now!

NewsJul.08,2025

-

High Quality Fifth Wheel Bracket for Heavy Loads – Best Discount Deals Online

NewsJul.08,2025

-

High Quality Fifth Wheel Coupling System for Trucks Best Fifth Wheel Coupling System Online

NewsJul.07,2025

-

High Quality & Best Volvo Trucks in Kansas City Discount Volvo Trucks for Sale

NewsJul.07,2025

-

High Quality & Best Standard Height of Tractor Trailer – Discount Prices Available

NewsJul.07,2025