Aza . 20, 2024 16:49 Back to list

fifth wheel rails for semi truck factory

Fifth Wheel Rails for Semi Truck Factories An Essential Component of Heavy-Duty Transportation

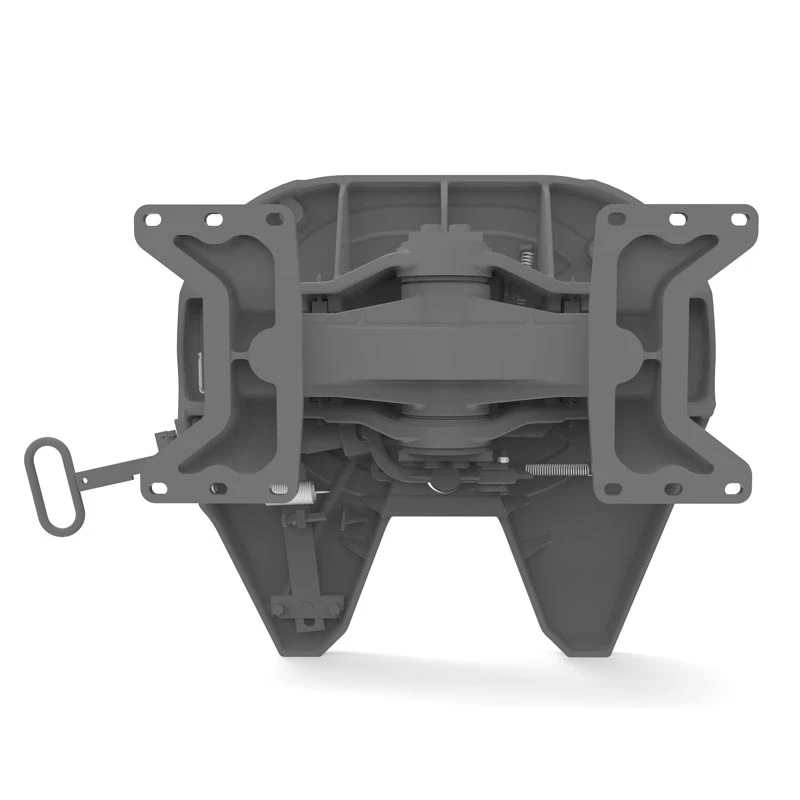

In the realm of heavy-duty transportation, where reliability and efficiency are paramount, the role of fifth wheel rails in semi trucks cannot be overstated. As the backbone of the hitching mechanism, fifth wheel rails facilitate the connection between the truck cab and the trailer, enabling the transportation of goods across vast distances. This article delves into the significance of fifth wheel rails, their manufacturing process, and the role they play in semi truck factories.

The Importance of Fifth Wheel Rails

Fifth wheel rails are crucial for ensuring the stability and safety of a truck and trailer combination. Designed to withstand the rigors of heavy loads and long hauls, these rails are typically made from high-strength steel or aluminum, offering both durability and lightweight performance. One of the primary roles of these rails is to provide a secure mounting point for the fifth wheel coupling, which is the mechanism that allows the trailer to pivot around the truck during turns.

Moreover, the positioning of the fifth wheel is critical for weight distribution. Improperly positioned fifth wheels can lead to difficulties in handling and increased wear and tear on tires and other components. Therefore, the design and manufacturing of fifth wheel rails must prioritize precision engineering to ensure optimal performance under various load conditions.

The Manufacturing Process

The manufacturing of fifth wheel rails involves several key steps, beginning with the selection of raw materials. High-quality steel or aluminum is chosen based on the specific requirements of the application. Once the materials are selected, they undergo processes such as cutting, bending, and welding to form the basic shape of the rails.

fifth wheel rails for semi truck factory

Advanced manufacturing techniques like CNC (Computer Numerical Control) machining play a significant role in ensuring accuracy and consistency. CNC machines precisely cut and shape the metal, reducing the risk of human error and allowing for mass production of components. After fabrication, the rails are subjected to rigorous quality control measures, which include testing for strength, durability, and dimensional accuracy.

Once manufactured, these fifth wheel rails are often treated with coatings to enhance their resistance to corrosion and wear. This is especially important for components exposed to harsh environmental conditions, as trucks frequently operate in diverse climates and terrains.

The Role of Technology in Manufacturing

In today's world, the integration of technology within manufacturing processes has revolutionized the way fifth wheel rails are produced. Automation, robotics, and advanced materials science have all contributed to improving efficiency and quality. For instance, the use of 3D modeling software allows engineers to simulate the performance of fifth wheel rails under various conditions before moving to production.

Moreover, the rise of Industry 4.0, characterized by interconnected manufacturing systems and data analytics, has enabled factories to optimize their operations. By analyzing data from production lines, manufacturers can identify bottlenecks, streamline processes, and enhance the quality of their products. This technological evolution ensures that fifth wheel rails meet the ever-increasing demands for safety, reliability, and performance.

Conclusion

In conclusion, fifth wheel rails are an indispensable component of semi trucks, playing a critical role in ensuring the safety and efficiency of freight transportation. The manufacturing of these rails involves meticulous engineering and utilizes advanced technology to meet rigorous industry standards. As heavy-duty transportation continues to evolve, the importance of high-quality fifth wheel rails will remain a top priority for manufacturers. By focusing on innovation and quality, semi truck factories can ensure that their products not only meet but exceed the expectations of operators, contributing to a safer and more efficient transportation network. The future of logistics depends on these robust and reliable components, highlighting the need for continuous improvement in their design and production processes.

-

Heavy-Duty 5th Wheel Hitch for Sale - Secure Your Towing!

NewsAug.24,2025

-

Durable Germany Type Suspension for Heavy Duty Trucks & Trailers

NewsAug.23,2025

-

American Type Welding Suspension Series: Strong, Reliable Hooks

NewsAug.22,2025

-

Hezhen 1-3mm Luminous Stone- Shijiazhuang Land Auto Component Ltd.|Durability&High Luminosity

NewsAug.18,2025

-

Hezhen 1-3mm Luminous Stone - Shijiazhuang Land Auto Component Ltd.

NewsAug.18,2025

-

Hezhen 1-3mm Luminous Stone - Shijiazhuang Land Auto Component Ltd.|Durable & Versatile

NewsAug.18,2025