máj . 23, 2025 10:11 Vissza a listához

Precision Towing in Motion: The Fifth Wheel’s Role in Reliable Hauling

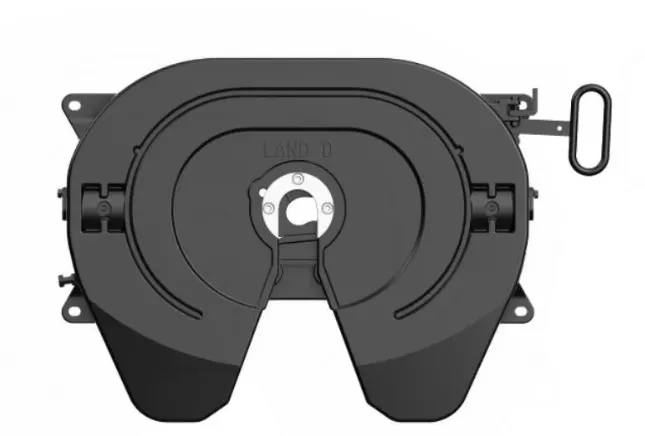

Hauling efficiency begins with a dependable ötödik kerék—a critical component in commercial and long-haul transportation. When optimized for lubrication, routine maintenance, and emergency readiness, the ötödik kerék mechanizmus transforms into a powerhouse of performance and safety. Whether you're exploring a new truck fifth wheel for sale or managing a high-mileage rig, the right hitch makes all the difference on the road.

The Correct Way to Lubricate the Fifth Wheel for Optimal Performance

Proper lubrication is essential to the long-term health and operational smoothness of a ötödik kerék. Without it, metal-on-metal contact creates excessive friction that wears down the ötödik kerék mechanizmus, leading to coupling failure or kingpin damage. But lubrication isn’t as simple as applying grease—technique and frequency matter.

Start by thoroughly cleaning off old grease and road debris. A degreaser or wire brush is recommended for the surface. Then, apply high-pressure moly grease to the top plate, focusing on the center and edges where the trailer rotates. In addition, the locking jaws and pivot points of the ötödik kerék should be lubricated using a grease gun with the appropriate fitting.

New nagy teherbírású nyerges vonószerkezet designs may feature grease channels or self-lubricating materials, making the process easier and more effective. Routine lubrication improves towing efficiency, extends component life, and ensures that the ötödik kerék mechanizmus functions smoothly even under the stress of daily hauls.

Inspection and Repair Cycles: How Often Should the Fifth Wheel Be Serviced?

Scheduled maintenance is the backbone of reliable towing, and understanding when to inspect and repair your ötödik kerék can prevent costly roadside breakdowns. For fleets that log high mileage, it is recommended that the ötödik kerék mechanizmus be visually inspected before every trip. Look for signs of wear, such as uneven contact surfaces, loose locking jaws, or excessive grease buildup.

Comprehensive inspections should be carried out every three months or every 25,000 miles. During these checks, technicians evaluate bushing wear, check the locking bar’s engagement with the kingpin, and verify that all bolts and pins are secure. If issues are detected, timely ötödik kerék javítás is essential to prevent the problem from escalating into a full-blown emergency.

Modern truck fifth wheel for sale units often include diagnostic indicators that assist drivers and fleet managers in monitoring wear over time. With this data-driven insight, maintenance schedules can be fine-tuned, extending the life and safety of the nagy teherbírású nyerges vonószerkezet system.

Emergency Protocols: What to Do If the Fifth Wheel Detaches While Towing

While rare, a ötödik kerék detachment during transit is one of the most critical emergencies a driver can face. Preparation is key. First, reduce speed gradually and avoid sharp steering to maintain control of the tractor. The trailer’s breakaway system should automatically engage, bringing it to a stop independently if the ötödik kerék mechanizmus fails completely.

Once stopped safely, assess the damage and ensure that the area is secure. If possible, document the condition of the ötödik kerék, kingpin, and trailer plate. Immediate ötödik kerék javítás will be required to determine the root cause—whether it’s locking failure, improper coupling, or mechanical breakdown.

Most importantly, every fleet should have emergency kits including reflective triangles, replacement pins, and communication tools. Investing in high-grade nagy teherbírású nyerges vonószerkezet systems with integrated safety locks dramatically reduces the chances of detachment and improves control in unexpected conditions.

Why Heavy Duty Fifth Wheel Hitches Dominate the Towing Industry

Durability, capacity, and engineering define a premium nagy teherbírású nyerges vonószerkezet. These systems are built to withstand thousands of pounds of vertical and lateral force, ensuring stable trailer positioning across highways, slopes, and rough terrain. Their robust construction not only supports increased load weight but also improves alignment, thanks to auto-centering features.

Unlike standard models, a nagy teherbírású nyerges vonószerkezet includes thicker top plates, dual-jaw locking designs, and a higher GCWR (Gross Combined Weight Rating). This makes them ideal for transporting oversized cargo, intermodal containers, and specialty trailers.

Fleet operators consistently choose these models over traditional hitches when browsing truck fifth wheel for sale options because they deliver unmatched performance under pressure. The enhanced resilience also means fewer service stops, reduced downtime, and an overall lower cost per mile—critical for competitive logistics operations.

Choosing the Right Truck Fifth Wheel for Sale: What Makes the Difference

Finding the perfect truck fifth wheel for sale depends on several factors—load type, operating environment, and frequency of use. Buyers should prioritize systems that offer low-maintenance design, certified durability, and compatibility with existing truck chassis.

Most leading ötödik kerék mechanizmus models today come with bolt-on or slide-mount configurations to suit short and long wheelbases. Buyers should also assess the jaw locking mechanism—dual-jaw systems offer tighter grip and longer service life. Additional features such as adjustable height, integrated air systems, and auto-latch engagement significantly improve safety and ease of use.

By sourcing from reputable vendors and verifying certifications, buyers ensure the ötödik kerék they purchase meets strict industry standards and performs flawlessly from day one. It’s no surprise that fleets looking to future-proof their equipment are turning to modern nagy teherbírású nyerges vonószerkezet setups that promise strength, flexibility, and ease of repair.

Fifth Wheel FAQs

How often should I lubricate the ötödik kerék?

For standard conditions, reapply grease every 2,000 to 3,000 miles. In extreme environments, lubrication should be done weekly. Always use moly-based grease and ensure even coverage across the top plate.

What’s the best way to handle a ötödik kerék mechanizmus failure on the road?

Slow down, avoid sudden maneuvers, and let the trailer’s breakaway system engage. Once safely stopped, inspect the ötödik kerék for damage and contact roadside service if ötödik kerék javítás is needed.

Are all truck fifth wheel for sale listings the same?

No. Different models vary in material quality, weight capacity, and features like auto-locking or sliding plates. Always match your selection to your vehicle type and hauling needs.

When is it time to replace a nagy teherbírású nyerges vonószerkezet?

Replace when there is visible wear on the locking jaws, uneven plate wear, or difficulty coupling. If ötödik kerék javítás becomes frequent, a full replacement ensures safety and performance.

Can I perform ötödik kerék javítás myself?

Basic cleaning and lubrication can be done at home, but for structural repairs or part replacement, professional service is recommended. Certified technicians ensure the ötödik kerék mechanizmus functions safely under heavy loads.

-

What Defines Excellence in Fifth Wheel Components and Their Manufacturers?

hírekJul.16,2025

-

Unveiling the Essentials of Fifth Wheel Systems in Heavy - Haul Transportation

hírekJul.16,2025

-

Unveiling the Essentials of Fifth Wheel Components in Commercial Transport

hírekJul.16,2025

-

Unveiling the Essence of Holland 5th Wheel Systems

hírekJul.16,2025

-

Unveiling the Dominance and Features of Holland Fifth Wheels

hírekJul.16,2025

-

Discovering the Diverse Landscape of Truck - Related Services and Offerings

hírekJul.16,2025