5月 . 23, 2025 10:06 リストに戻る

Commanding Control on Every Haul: Why the Fifth Wheel Dominates the Heavy-Duty Towing Market

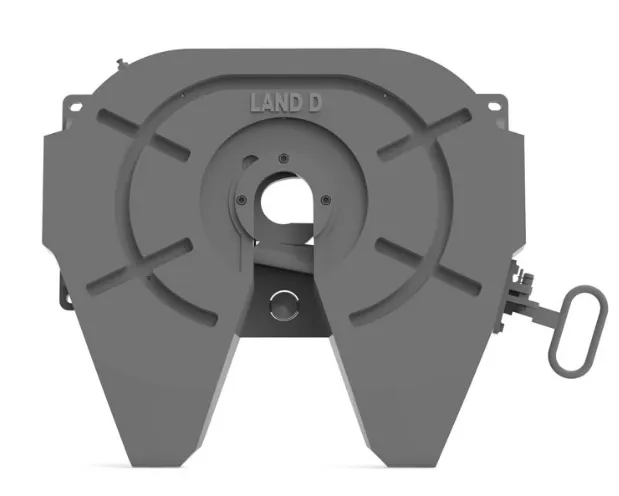

The power of reliable towing lies in one engineering masterpiece—the 第5輪. Whether used in logistics, construction, or long-haul transport, the fifth wheel mechanism remains the heart of modern trailer connectivity. With increasing demand for efficient load distribution and safety during transport, the surge in searches for truck fifth wheel for sale signals the growing reliance on this critical component across global fleets.

Fifth Wheel vs Gooseneck Trailer: What’s the Best Choice for Heavy Loads?

When choosing between a 第5輪 and a gooseneck trailer, one primary factor dominates the decision: load capacity. The fifth wheel mechanism is explicitly engineered for heavier, industrial-grade towing. Its wide-plate design distributes trailer weight evenly across the tractor’s rear axle, providing greater stability and traction. This makes it the preferred option for long-distance and cross-country transport of commercial freight.

In contrast, gooseneck hitches are more commonly found in agricultural or light-duty utility settings. They may offer tighter turning radii, but they cannot match the vertical load capacity or road stability of a heavy duty fifth wheel hitch. Businesses that prioritize performance under pressure, like logistics or machinery haulers, overwhelmingly choose 第5輪 systems because of their robust construction and improved weight-bearing performance.

The market reflects this preference. More fleet owners are searching for a truck fifth wheel for sale as they upgrade their towing systems for higher capacity and tighter safety standards, making the 第5輪 the undisputed champion for industrial transport.

What to Do When the Trailer Shakes: How to Adjust the Fifth Wheel

Trailer instability during transit is a common concern. A shaking or swaying trailer can indicate improper alignment or worn components within the fifth wheel mechanism. The solution often lies in a simple but precise adjustment of the coupling plate.

First, verify that the trailer’s kingpin is properly seated in the jaws of the 第5輪. If misaligned, unlocking and recoupling may be necessary. For sliding 第5輪 setups, adjusting the forward or rearward positioning of the plate can redistribute the load weight, reducing trailer sway and improving steering responsiveness.

Maintenance checks are also key. A worn or loose jaw locking system might cause excessive movement during motion. In such cases, professional 五輪修理 becomes essential to restore safe performance. Replacing damaged bushings, adjusting the locking mechanism, or adding fresh grease can significantly reduce trailer vibration.

Understanding how to diagnose and fine-tune a fifth wheel mechanism not only ensures a smoother haul but also extends the life of the hitch system and reduces wear on other vehicle components.

A Closer Look at the Fifth Wheel’s Role in Industrial Growth

The commercial transportation industry is experiencing a shift toward heavier, longer hauls. With this shift comes a spike in demand for high-capacity hitches. The global need for dependable heavy duty fifth wheel hitch systems has driven a new wave of innovation, with manufacturers refining materials, locking mechanisms, and installation efficiency to meet industrial expectations.

These systems now come equipped with air-release technology, adjustable locking pressure, and low-maintenance coatings—all designed to reduce downtime and maximize operational continuity. The rise in online listings for truck fifth wheel for sale reflects this trend, as businesses seek modern hitches that combine strength with simplicity.

From cross-border trucking to oversized equipment hauling, the 第5輪 is no longer optional—it’s foundational. Its ability to handle both vertical and horizontal forces makes it the most efficient connector in the heavy-duty transport sector. Compared to traditional ball hitches or gooseneck systems, it offers superior safety, control, and adaptability to modern logistics needs.

Routine Repair and Care: Extending the Life of the Fifth Wheel

Even the most robust 第5輪 will require attention over time. Keeping this system in peak condition is essential to avoid failures on the road. Routine inspections of the fifth wheel mechanism should include checking for wear in the jaw and kingpin interface, verifying lubrication levels, and looking for cracks or rust in the mounting plate.

Timely 五輪修理 can involve simple fixes like jaw tightening or more extensive overhauls such as replacing worn slide rails or locking levers. Some modern systems now feature wear indicators or built-in maintenance alerts, helping fleet managers schedule service before critical failure occurs.

Trusted 五輪修理 services also use OEM parts and certified technicians, ensuring that the hitch functions safely under extreme weight and weather conditions. With growing demand and more hours on the road, investing in regular care has become a key strategy for cost control and safety assurance in any heavy-duty fleet.

Fifth Wheel FAQs

What makes a 第5輪 more suitable than a gooseneck for heavy loads?

The 第5輪 provides superior weight distribution and load stability, making it better suited for large, heavy trailers compared to gooseneck systems. It ensures better control during high-speed or long-distance hauls.

How can I tell if my fifth wheel mechanism needs adjustment?

Signs like trailer shaking, difficult coupling, or excessive noise during turns may indicate misalignment or wear in the fifth wheel mechanism. Repositioning or tightening may be needed to restore performance.

Where can I find a truck fifth wheel for sale that meets heavy-duty standards?

Look for commercial vehicle parts suppliers or OEM platforms that specialize in industrial towing solutions. Verified listings for truck fifth wheel for sale often include technical specs, certifications, and compatibility guides.

What is involved in routine 五輪修理?

Common 五輪修理 tasks include re-lubrication, replacing jaw parts, realigning slide mechanisms, and inspecting weld points. Periodic repairs ensure safe, reliable operation even under demanding loads.

Why is a heavy duty fifth wheel hitch critical for modern fleets?

A heavy duty fifth wheel hitch supports higher vertical and drawbar loads while offering advanced safety features like double-lock jaws and self-lubricating plates. It’s essential for today’s long-haul and industrial fleets.

-

What Defines Excellence in Fifth Wheel Components and Their Manufacturers?

ニュースJul.16,2025

-

Unveiling the Essentials of Fifth Wheel Systems in Heavy - Haul Transportation

ニュースJul.16,2025

-

Unveiling the Essentials of Fifth Wheel Components in Commercial Transport

ニュースJul.16,2025

-

Unveiling the Essence of Holland 5th Wheel Systems

ニュースJul.16,2025

-

Unveiling the Dominance and Features of Holland Fifth Wheels

ニュースJul.16,2025

-

Discovering the Diverse Landscape of Truck - Related Services and Offerings

ニュースJul.16,2025