Jun . 03, 2025 13:56 Zréck op d'Lëscht

Unveiling the Critical Components of Trailer - Tractor Interfaces

In the realm of heavy - duty transportation, the seamless integration of trailers with tractors hinges on a suite of essential components. These elements, including the 5th wheel parts catalog, 5th wheel locking mechanism, Trailer Lenkung System,an an trailer landing legs, play pivotal roles in ensuring safety, efficiency, and functionality. From securing the connection between vehicles to enabling precise maneuvering and stable parking, each component contributes to the overall performance of the trailer - tractor assembly, facilitating the reliable movement of goods across long distances.

Navigating the 5th Wheel Parts Catalog for Optimal Maintenance

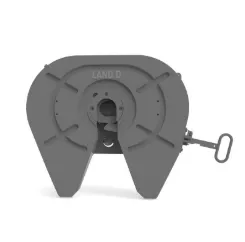

A comprehensive 5th wheel parts catalog serves as a vital resource for fleet managers, mechanics, and trucking enthusiasts. These catalogs detail a wide array of components, from replacement plates and locking pins to lubrication kits and wear pads. For instance, within the catalog, one can find specialized parts designed to withstand the rigors of heavy - hauling operations. A well - maintained 5th wheel is crucial for safe towing, and the catalog provides clear specifications for each part, ensuring compatibility with different 5th - wheel models. Whether it's sourcing a new release handle or replacing a worn - out cushion ring, the 5th wheel parts catalog offers detailed diagrams and descriptions, enabling users to identify and order the exact components needed for repairs or upgrades.

The Crucial Role of the 5th Wheel Locking Mechanism

At the heart of the trailer - tractor connection lies the 5th wheel locking mechanism, a highly engineered system designed to prevent separation during transit. Modern 5th - wheel locks feature multi - point engagement systems that securely clamp onto the trailer's kingpin. For example, some advanced mechanisms use a combination of jaws and locking pins to create a tight, vibration - resistant connection. This mechanism must withstand significant vertical and horizontal forces generated during acceleration, braking, and cornering. Regular inspection and maintenance of the 5th wheel locking mechanism are essential; worn - out components, such as locking jaws or release springs, can compromise safety. A malfunctioning lock may lead to trailer detachment, resulting in catastrophic accidents. Therefore, manufacturers emphasize the importance of adhering to strict maintenance schedules to ensure the integrity of this critical component.

Enhancing Maneuverability with the Trailer Steering System

Déi Trailer Lenkung System revolutionizes the handling of large trailers, particularly in tight spaces. Unlike traditional rigid - axle trailers, those equipped with advanced steering systems can pivot their axles, reducing the turning radius and improving overall maneuverability. In urban delivery scenarios, where navigating narrow streets and tight loading docks is common, these systems allow drivers to execute precise turns with ease. Some trailer steering systems are hydraulically or electronically controlled, enabling seamless communication between the tractor and trailer. Sensors detect the tractor's steering input and adjust the trailer's axles accordingly, minimizing tire wear and enhancing road stability. This technology not only improves operational efficiency but also extends the lifespan of trailer components by reducing stress on tires and axles.

Ensuring Stability with Trailer Landing Legs

Trailer landing legs are indispensable for supporting the weight of the trailer when it is detached from the tractor. Constructed from durable steel or aluminum, these legs are designed to bear heavy loads without buckling or collapsing. When a trailer is parked for loading or unloading, the landing legs are extended to the ground, distributing the weight evenly. Some models feature adjustable height settings, allowing operators to level the trailer on uneven surfaces. Additionally, certain trailer landing legs incorporate features such as self - lubricating bushings and corrosion - resistant coatings, ensuring smooth operation and longevity. Regular inspection of the landing legs is crucial; bent or damaged legs can compromise the stability of the trailer, leading to potential accidents during loading or unloading operations.

FAQ Regarding Trailer - Tractor Components

How often should I refer to the 5th wheel parts catalog for maintenance?

Regular maintenance schedules vary based on usage and operating conditions. For high - mileage fleets, it is advisable to consult the 5th wheel parts catalog at least once every 6 months or every 100,000 miles, whichever comes first. However, if you notice signs of wear, such as excessive play in the 5th - wheel connection or difficulty engaging the lock, immediate inspection and potential part replacement may be necessary.

What are the signs of a failing 5th wheel locking mechanism?

Indications of a deteriorating 5th wheel locking mechanism include difficulty locking or unlocking the mechanism, excessive noise during operation, and visible wear on the locking jaws or pins. If you observe the trailer shifting or rattling while in transit, it could signal a problem with the lock. Promptly addressing these issues is essential to prevent trailer detachment.

How can I optimize the performance of my trailer steering system?

To maximize the efficiency of the Trailer Lenkung System, ensure regular lubrication of all moving parts, including pivot points and hydraulic components. Check for leaks in hydraulic lines and replace worn - out seals promptly. Additionally, calibrate the steering system according to the manufacturer's specifications to ensure accurate response to the tractor's steering input.

Can I replace trailer landing legs on my own?

While it is possible to replace trailer landing legs without professional assistance, it requires mechanical expertise and the proper tools. Before attempting a replacement, carefully review the manufacturer's instructions in the product manual. If you are unsure or lack experience, it is recommended to seek help from a qualified technician to ensure proper installation and avoid potential safety hazards.

What factors should I consider when choosing trailer landing legs?

When selecting trailer landing legs, consider the weight capacity, material (steel or aluminum), adjustability, and ease of operation. Choose legs with a weight capacity that exceeds the maximum loaded weight of your trailer for added safety. Additionally, opt for models with features like corrosion - resistant coatings and self - lubricating components to minimize maintenance requirements.

-

What Defines Excellence in Fifth Wheel Components and Their Manufacturers?

NeiegkeetenJul.16,2025

-

Unveiling the Essentials of Fifth Wheel Systems in Heavy - Haul Transportation

NeiegkeetenJul.16,2025

-

Unveiling the Essentials of Fifth Wheel Components in Commercial Transport

NeiegkeetenJul.16,2025

-

Unveiling the Essence of Holland 5th Wheel Systems

NeiegkeetenJul.16,2025

-

Unveiling the Dominance and Features of Holland Fifth Wheels

NeiegkeetenJul.16,2025

-

Discovering the Diverse Landscape of Truck - Related Services and Offerings

NeiegkeetenJul.16,2025