Lap . 20, 2024 22:42 Back to list

fifth wheel coupling mechanism factories

Understanding Fifth Wheel Coupling Mechanism A Look at Factories and Production

The fifth wheel coupling mechanism is a critical component in the realm of transportation, particularly regarding heavy-duty trailers and road vehicles. It serves as the connection point between a truck and its trailer, allowing for smooth articulation and movement during operation. As global demand for freight transportation continues to rise, factories specializing in the production of fifth wheel couplings are increasingly significant in the supply chain.

What is a Fifth Wheel Coupling?

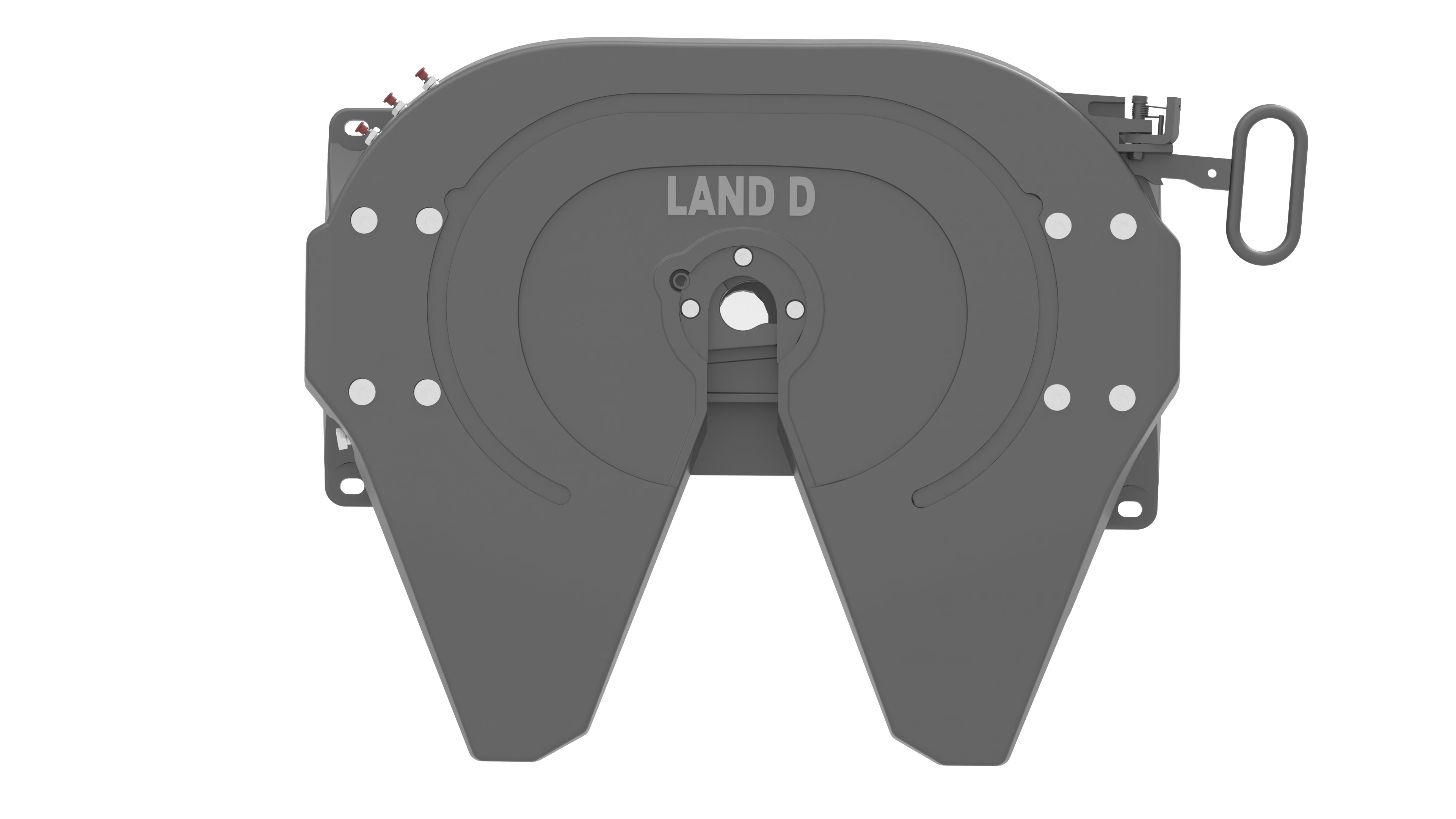

The fifth wheel is a type of coupling system typically mounted on the rear of a truck or tractor. Its design allows for a reliable connection to a trailer, enabling the vehicle to support heavy loads while offering flexibility for directional changes. This mechanism consists of a circular plate and a locking mechanism, which ensures a secure attachment to the trailer’s kingpin. The unique design of the fifth wheel allows for vertical pivoting, accommodating the trailer's movements while maintaining stability and control.

Importance of Fifth Wheel Coupling in Industries

Fifth wheel couplings are indispensable in various industries, including logistics, freight transportation, and construction. They facilitate the safe transport of goods and materials across long distances. The efficiency and safety of these operations rely greatly on the integrity of the fifth wheel coupling. A malfunction can lead to accidents, product damage, or delays in delivery, making quality manufacturing essential.

The Manufacturing Process

The production of fifth wheel couplings involves several critical stages. Factories usually start with the sourcing of high-grade materials such as stainless steel or forged steel, known for their strength and durability. The manufacturing process includes machining, welding, and surface treatment to create a robust, corrosion-resistant product.

Design and Engineering Advanced computer-aided design (CAD) technologies are leveraged to engineer the coupling mechanisms. These designs are rigorously tested through simulations before production begins, ensuring that the final product can withstand the stresses of heavy cargo and varying environmental conditions.

fifth wheel coupling mechanism factories

Machining and Assembly After raw materials are shaped into specific parts using CNC machines, they are assembled in a controlled environment. Quality control measures are incorporated at each step of the assembly process to uphold industry standards.

Finishing Touches The finished couplings undergo surface treatments to enhance their resistance to corrosion and wear. Painting or coating with specialized materials is a common practice, especially for units intended for use in harsh environments.

Quality Assurance in Fifth Wheel Coupling Production

Quality assurance is paramount in the production of fifth wheel couplings. Many factories adhere to international quality standards such as ISO 9001, which emphasizes systematic processes and continuous improvement. Regular inspections, both during and after production, ensure that only couplings meeting strict safety and performance criteria are dispatched to the market.

Innovations in the Industry

Recent advancements in technology have led to innovations in fifth wheel coupling designs. Smart couplings with integrated sensors are being developed, providing real-time data on the coupling's condition, load distribution, and potential issues. These innovations aim to enhance safety and efficiency in transport, aligning with the growing trend of automation in the logistics industry.

Conclusion

As the demand for efficient freight transportation persists, the significance of reliable fifth wheel coupling mechanisms cannot be overstated. Factories dedicated to their production play a crucial role in ensuring that transport vehicles operate safely and effectively. With ongoing advancements in manufacturing techniques and a commitment to quality, the future of fifth wheel couplings appears bright, promising enhanced safety features and more efficient operations in the logistics sector. Understanding the intricate process behind these vital components can provide deeper insight into the backbone of global shipping and transportation.

-

Nuss Truck Sauk Rapids - High Quality, Best Deals & Discounts Available

NewsJul.08,2025

-

High Quality Kingpin Adalah – Best Kingpin Adalah for Trucks, Get Discount Kingpin Adalah Now!

NewsJul.08,2025

-

High Quality Fifth Wheel Bracket for Heavy Loads – Best Discount Deals Online

NewsJul.08,2025

-

High Quality Fifth Wheel Coupling System for Trucks Best Fifth Wheel Coupling System Online

NewsJul.07,2025

-

High Quality & Best Volvo Trucks in Kansas City Discount Volvo Trucks for Sale

NewsJul.07,2025

-

High Quality & Best Standard Height of Tractor Trailer – Discount Prices Available

NewsJul.07,2025