Lap . 23, 2024 18:17 Back to list

lube inserts company

The Significance of Lube Inserts in Modern Industries

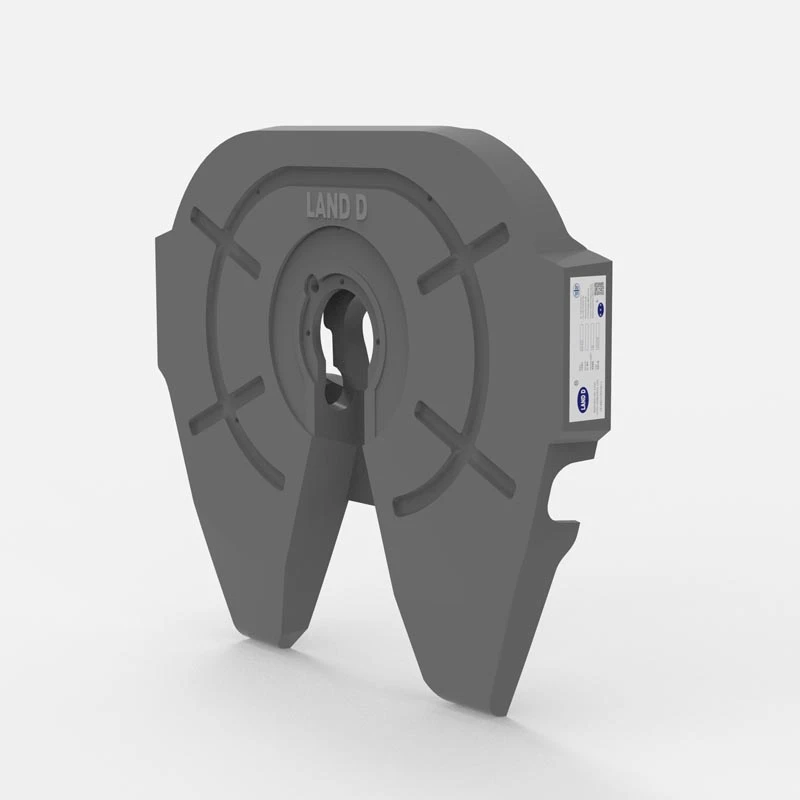

In the fast-paced world of manufacturing, efficiency and precision are paramount. As companies strive to optimize their production processes, one often overlooked but critical component is the lube insert. These small tools play a significant role in enhancing the performance and longevity of machinery, ultimately contributing to a company's bottom line.

Lube inserts are specially designed components used in various machining processes to introduce lubrication directly to the cutting edge. This localized lubrication reduces friction and heat, which can significantly affect tool life and workpiece quality. By minimizing these adverse factors, lube inserts help maintain optimal operating temperatures, ensuring that machines operate smoothly without overheating or excessive wear.

The Significance of Lube Inserts in Modern Industries

Moreover, lube inserts contribute to cost savings for manufacturers. By extending the life of cutting tools, companies can reduce their expenditure on replacements and maintenance. Tools that last longer mean less downtime, allowing for uninterrupted production runs. Additionally, the reduced friction and heat generation can lead to lower energy consumption, further contributing to cost efficiency.

lube inserts company

The versatility of lube inserts is another significant advantage. They can be applied in various machining operations, including turning, milling, and drilling, making them a valuable asset for companies that employ multiple processes. This flexibility means that businesses can standardize their manufacturing practices, simplifying inventory management and training for employees.

In industries where precision and quality are non-negotiable, such as aerospace and automotive, the role of lube inserts becomes even more critical. These sectors often operate under stringent specifications, and any deviation in quality can result in severe consequences. Lube inserts allow manufacturers to adhere to tight tolerances while maintaining the integrity of their tools and equipment.

As technology continues to evolve, the design and functionality of lube inserts are also advancing. Innovations, such as adaptive lubrication systems that adjust the lubrication flow based on real-time cutting conditions, are becoming increasingly prevalent. These advancements ensure that the lubrication process is not only efficient but also adaptive to varying operational demands.

In conclusion, lube inserts are essential components in the realm of modern machining, significantly contributing to enhanced efficiency, cost savings, and product quality. As industries continue to challenge themselves with new manufacturing targets, the importance of integrating advanced tools like lube inserts cannot be overstated. Companies that invest in such technologies are not just optimizing their current processes but are also paving the way for future innovations in manufacturing. By leveraging the benefits of lube inserts, businesses can ensure they remain competitive in an ever-evolving marketplace.

-

Imperial Truck Repair Hayward CA - High Quality, Affordable & Reliable Services

NewsJun.10,2025

-

High Quality Fontaine International do Brasil – Best Discount Offers Online

NewsJun.10,2025

-

Premium Fontaine Valves - High Quality & Discount Offers Durable

NewsJun.10,2025

-

Premium Fifth Wheel King Pins Top Durability & Savings

NewsJun.10,2025

-

Best Semi Trailer Kingpins for Sale Premium & Discounted

NewsJun.10,2025

-

Premium Holland Fifth Wheel Slider Parts Durable & Discount Deals

NewsJun.09,2025