अगस्ट . 17, 2024 13:21 Back to list

Issues with Fifth Wheel Not Securing Properly for Exporters and Transportation Solutions

Understanding the Challenges of 5th Wheel Not Locking and Its Impact on Exporters

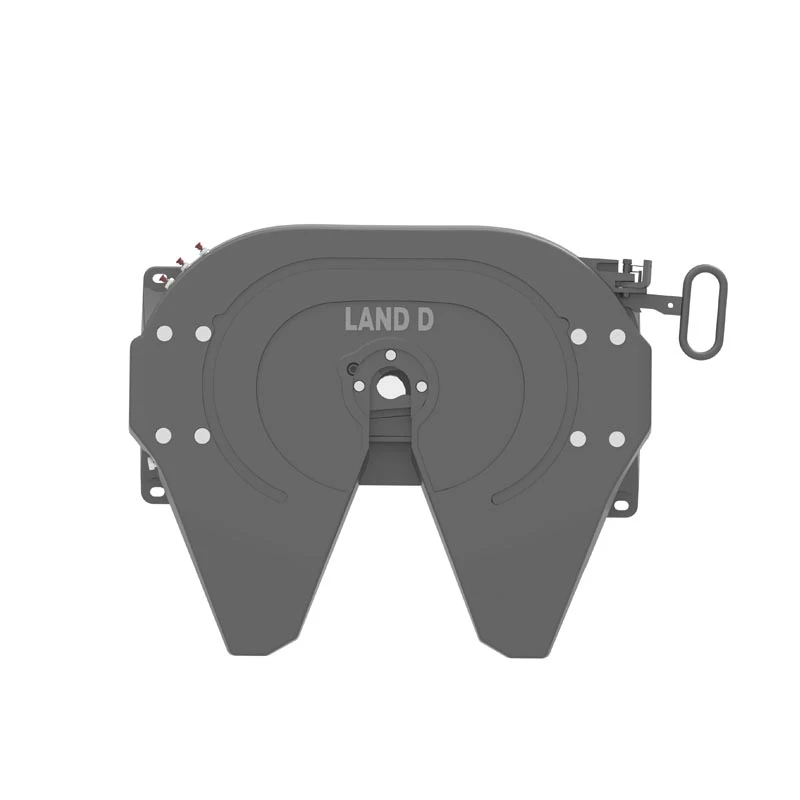

The fifth wheel coupling system is a crucial component in the transportation industry, particularly for heavy-duty trucks and trailers. It serves as a connection point between the tractor and the trailer, allowing for safe and effective towing. However, one of the prevalent issues that operators face is the malfunctioning of the fifth wheel, specifically, it not locking properly. This problem can have significant implications, especially for exporters relying on timely deliveries and efficient logistics.

The Mechanics of the Fifth Wheel

The fifth wheel operates using a locking mechanism that secures the trailer to the tractor. When the trailer is coupled, a locking jaw engages with the kingpin of the trailer, ensuring that it remains securely attached during transit. However, if the fifth wheel fails to lock, it poses risks such as swaying, detachment, and, in worst-case scenarios, accidents on the road. For exporters, the potential for delays in delivery and increased costs due to damaged goods or equipment cannot be overlooked.

Identifying the Causes of Malfunction

A multitude of factors can contribute to the failure of the fifth wheel to lock effectively. One common issue is the buildup of dirt and grime in the locking mechanism. Conditions that are typical in loading and unloading zones can lead to contaminants obstructing proper function. Additionally, wear and tear on the locking components due to regular use or lack of maintenance can also result in malfunction. Another significant factor is improper coupling, where the driver may not engage the locking mechanism correctly, leading to safety risks.

Impacts on Exporters

5th wheel not locking exporters

When exporters experience issues with the fifth wheel not locking, the ramifications extend beyond mere inconvenience. Shipment delays can result in missed deadlines, which can damage relationships with clients and sometimes lead to penalties. Moreover, if an un-locked trailer detaches while in transit, the consequences can be catastrophic—not just in terms of lost cargo but also in terms of liability and potential legal actions.

The financial implications are substantial as well. Each incident involving mechanical failure can lead to costly repairs, increased insurance premiums, and the need for alternative transport solutions, all of which can significantly impact profit margins. Exporters must also consider the reputation of their brand; consistent mechanical failures can harm consumer confidence and deter future business.

Prevention and Solutions

To mitigate the risks associated with the fifth wheel not locking, exporters should prioritize preventive measures. Regular maintenance checks of the coupling system are essential. This includes cleaning the fifth wheel often, inspecting it for wear and tear, and ensuring that all components are properly lubricated. Driver training is equally important; operators must be educated on correct coupling procedures and the importance of verifying that the locking mechanism is secure.

In addition, investing in modern technology can enhance safety and efficiency. Many contemporary tractors and trailers come equipped with advanced systems that include visual or audible alerts to indicate when a trailer is properly locked. Implementing these technologies can provide an added layer of security for exporters.

Conclusion

The challenge of the fifth wheel not locking is one that exporters cannot afford to ignore. From delayed shipments to significant financial repercussions, the impacts are far-reaching. Through regular maintenance, effective training, and the adoption of new technologies, exporters can safeguard their operations against the risks associated with fifth wheel malfunctions. Maintaining a secure connection between tractor and trailer is not merely a technical necessity; it is a critical element of successful export logistics.

-

Imperial Truck Repair Hayward CA - High Quality, Affordable & Reliable Services

NewsJun.10,2025

-

High Quality Fontaine International do Brasil – Best Discount Offers Online

NewsJun.10,2025

-

Premium Fontaine Valves - High Quality & Discount Offers Durable

NewsJun.10,2025

-

Premium Fifth Wheel King Pins Top Durability & Savings

NewsJun.10,2025

-

Best Semi Trailer Kingpins for Sale Premium & Discounted

NewsJun.10,2025

-

Premium Holland Fifth Wheel Slider Parts Durable & Discount Deals

NewsJun.09,2025