Dec . 29, 2024 06:40 Back to list

50k fifth wheel hitch factories

Understanding the 50k Fifth Wheel Hitch Factories A Comprehensive Overview

The fifth wheel hitch is a crucial component in the world of towing, particularly for heavy trailers, campers, and recreational vehicles. Unlike traditional tow hitches, fifth wheel hitches are designed to offer superior weight distribution and stability when towing larger loads. As the demand for such hitches grows, especially with the rise in popularity of RV camping and long-haul trucking, so too does the necessity for robust manufacturing capabilities. This article delves into the landscape of factories producing 50k fifth wheel hitches, examining their production processes, technologies, and the overall market dynamics.

The Evolution of Fifth Wheel Hitches

Fifth wheel hitches have evolved significantly since their inception. Originally designed for horse-drawn vehicles, modern fifth wheel hitches now boast advanced engineering and materials that ensure durability, strength, and safety. A 50k fifth wheel hitch is one rated to handle loads up to 50,000 pounds, making it suitable for heavy-duty applications. Such capabilities are particularly important for industries that require reliable towing solutions, including construction, agriculture, and logistics.

The Importance of Factory Standards

Factory standards play a crucial role in the reliability and safety of fifth wheel hitches. Manufacturers must adhere to various regulatory guidelines, which ensure that their products meet rigorous safety and performance benchmarks. These standards cover everything from the materials used in construction to the testing processes that assess the hitches’ performance under extreme conditions. A reputable factory producing 50k fifth wheel hitches will typically have a certification that verifies compliance with these industrial standards, thereby instilling confidence in consumers and business operators alike.

Advanced Manufacturing Techniques

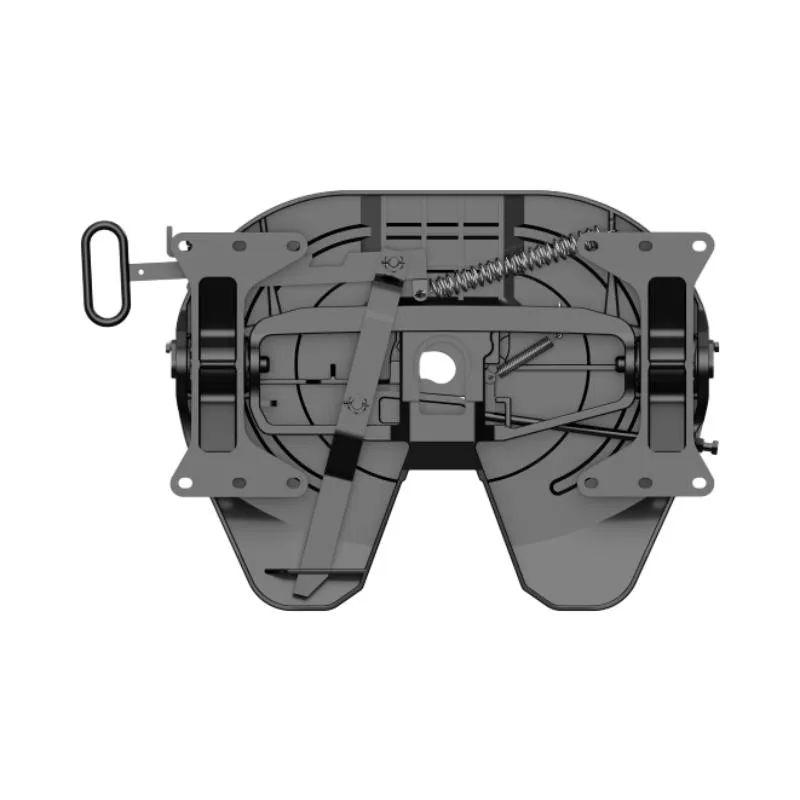

The production of a high-quality 50k fifth wheel hitch involves several advanced manufacturing techniques. The process often begins with high-grade steel or aluminum, chosen for their strength-to-weight ratios. Cutting-edge machining processes, such as CNC (Computer Numerical Control) machining, allow for precision shaping and cutting of the materials. Automated welding techniques further enhance the reliability of the hitches, ensuring that all joints can withstand the high stresses involved in towing heavy loads.

50k fifth wheel hitch factories

In addition to traditional manufacturing methods, some factories have begun to integrate modern technologies like 3D printing for prototyping and design customization. This innovative approach enables manufacturers to develop and test new hitch designs rapidly, significantly reducing the time from concept to market. Factories focusing on research and development are crucial for maintaining competitiveness as consumer preferences and technology evolve.

Global Market Dynamics

The market for fifth wheel hitches, particularly those rated at 50k, is influenced by various global factors. The increasing popularity of RVing and outdoor activities has led to a surge in demand for towing solutions in the consumer segment. Concurrently, the logistics and transportation sectors require heavy-duty towing capabilities for their operations, further propelling the need for robust fifth wheel hitches.

Emerging economies have also begun to contribute to this market growth. As infrastructure projects ramp up and transportation networks expand globally, more businesses require dependable towing solutions. This growth drives factories to enhance their production capacities and adopt innovative practices to meet the increasing demand.

Sustainability in Manufacturing

Another critical consideration for fifth wheel hitch factories is sustainability. As environmental concerns become more prominent, many manufacturers are adopting greener practices in their production processes. This includes utilizing recycled materials, reducing energy consumption during manufacturing, and implementing waste reduction strategies. By prioritizing sustainability, factories not only comply with regulations but also appeal to environmentally conscious consumers.

Conclusion

In summary, the landscape of 50k fifth wheel hitch factories is dynamic and multifaceted. With a strong foundation in advanced manufacturing processes, adherence to safety and regulatory standards, and responsiveness to market demands, these factories play an essential role in supplying high-quality towing solutions. As technology advances and consumer preferences shift, these manufacturers will continue to adapt, ensuring they remain at the forefront of the industry while promoting sustainable practices. For individuals and businesses alike, understanding the capabilities and offerings of these factories will be vital to making informed purchasing decisions for all towing needs.

-

Nuss Truck Sauk Rapids - High Quality, Best Deals & Discounts Available

NewsJul.08,2025

-

High Quality Kingpin Adalah – Best Kingpin Adalah for Trucks, Get Discount Kingpin Adalah Now!

NewsJul.08,2025

-

High Quality Fifth Wheel Bracket for Heavy Loads – Best Discount Deals Online

NewsJul.08,2025

-

High Quality Fifth Wheel Coupling System for Trucks Best Fifth Wheel Coupling System Online

NewsJul.07,2025

-

High Quality & Best Volvo Trucks in Kansas City Discount Volvo Trucks for Sale

NewsJul.07,2025

-

High Quality & Best Standard Height of Tractor Trailer – Discount Prices Available

NewsJul.07,2025