Oct . 13, 2025 11:05 Back to list

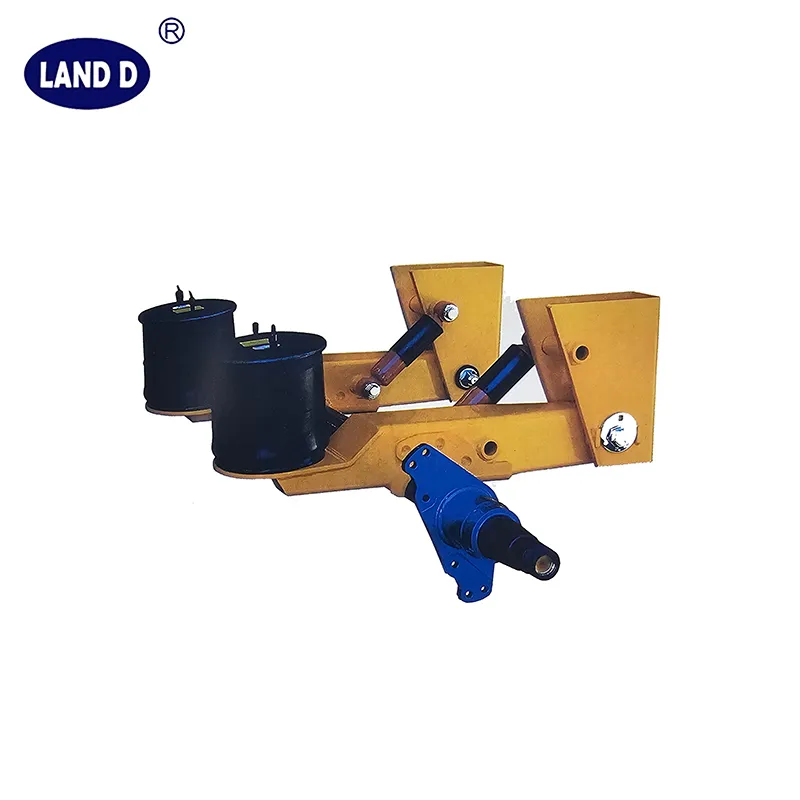

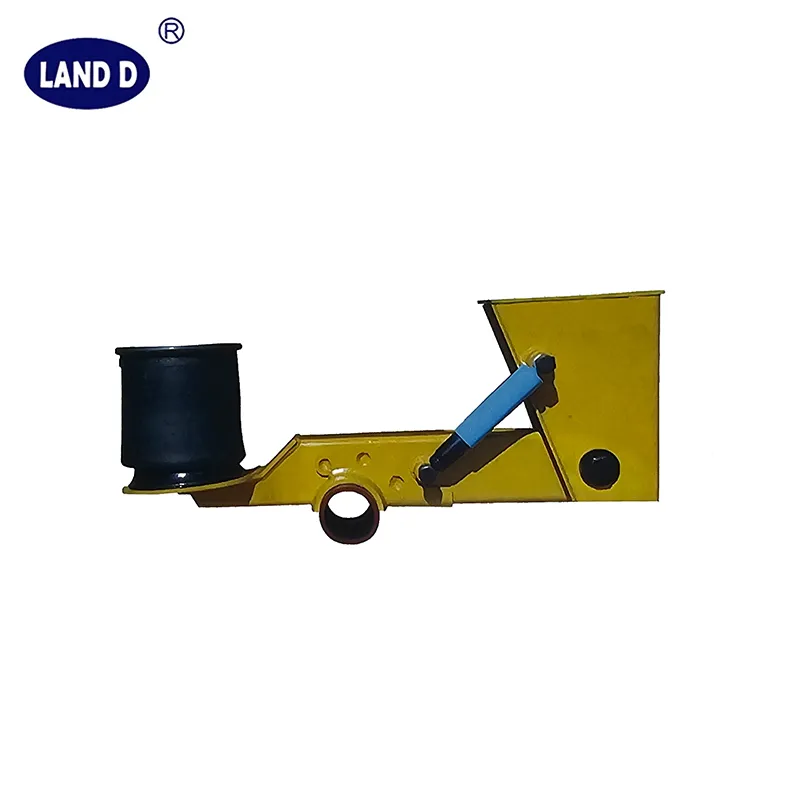

Air Suspension Series: Adjustable, Durable, Load-Leveling

Practical Field Notes on the Air Suspension Series for Trailers & Semi Trucks

I’ve been around heavy-duty fleets long enough to know what keeps uptime high: stable ride, predictable wear, and parts that don’t complain in winter. The Air Suspension Series coming out of Shijiazhuang City, Hebei Province, China, has been quietly making waves—partly because it’s not flashy; it’s practical. And, to be honest, that’s what operators ask for.

Industry trend check

Fleets are shifting from leaf to air to protect cargo, reduce tire scrub, and keep axle loads balanced. In fact, many customers say the real value shows up in fewer driver complaints and less damage to sensitive goods. The Air Suspension Series leans into that: lighter structures, corrosion-minded coatings, and bushings that don’t “squeak out” after a single salt season.

Typical technical specs (field-verified ranges)

| Item | Spec (≈ / around) |

|---|---|

| Rated axle load (per axle) | ≈ 9–13 t (real-world use may vary) |

| Ride height | ≈ 250–380 mm adjustable |

| Max air spring pressure | ≈ 0.8 MPa (8 bar) |

| Temperature range | -40°C to +70°C |

| Bushing hardness | ≈ 70–80 Shore A (NVH tuned) |

| Coating | E-coat + powder (salt spray 240–500 h) |

| Service life (bench) | ≥ 1.5–2.0 million cycles |

| Weight saving vs. leaf | ≈ 18–25 kg/axle |

How it’s built (short version)

- Materials: high-tensile steel arms/crossmembers, vulcanized rubber bellows, sealed bushings, zinc-plated bolts.

- Methods: robotic welds, shot blasting, e-coat dip, powder topcoat, torque traceability on fasteners.

- Testing: fatigue ≥ 2.0M cycles @ 7 bar; ISO 9227 salt spray 384 h; low-temp drop to -40°C; air-leak ≤ 2%/24 h.

- Service life: fleets report 3–5 years between major overhauls with standard PMs (to be fair: duty cycle matters).

- Certs/QMS: ISO 9001, IATF 16949 lineage; brake interfaces designed around FMVSS 121 and SAE J1402 hose compat.

Application scenarios: long-haul box and reefer trailers, bulk tankers needing low vibration, city logistics (ride-height dumps at docks), and yes—some off-pavement mining support where articulation helps keep tires alive. Surprisingly resilient in coastal climates if you rinse regularly.

What operators notice

- Driver feedback: less bounce, fewer “shock-through” events on bridge joints.

- Cargo protection: claims decline on fragile loads (glass, dairy, electronics)—anecdotally 10–20% in some fleets.

- Maintenance: bushing swaps are straightforward; air lines standardized for quick connect (SAE-compliant).

Recent batch test data: 2.2M fatigue cycles passed, salt spray 384 h to red rust onset on edges, noise reduction ≈ 3–5 dB in cab over rough concrete vs. a baseline leaf setup.

Vendor snapshot (what buyers compare)

| Vendor | Lead time | Testing & Certs | Customization | Price |

|---|---|---|---|---|

| L&J (Shijiazhuang, China) | ≈ 20–35 days | IATF lineage, ISO 9001, FMVSS 121 alignment tests | Ride height, brackets, bushing durometer | Value-tier |

| Global Brand A | ≈ 30–45 days | IATF 16949, extensive NVH labs | Wide platform options | Premium |

| Regional Maker B | ≈ 15–25 days | ISO 9001, basic fatigue only | Limited | Budget |

Customization and integration

Spec your Air Suspension Series with custom hanger brackets, axle seats for popular axle makes, and tuned ride-height valves. For tanker fleets, ask for anti-roll bar pairing; for city trailers, quick-dump kits speed docking. I guess the trick is sharing real axle weights and duty cycles—engineering will match bellows volume and shock valving accordingly.

Mini case studies

- Reefer fleet (coastal): reported 12% tire life gain and fewer pallet shift claims after switching to Air Suspension Series.

- Cement additive tanker: drivers liked height control at uneven silos; maintenance noted easier bushing service at 150k km.

Standards referenced

Design and validation take cues from IATF 16949 QMS, ISO 9227 corrosion tests, FMVSS 121 air brake performance, and SAE J1402 hose compatibility.

- IATF 16949:2016 – https://www.iatfglobaloversight.org/standard/iatf-16949/

- ISO 9227:2017 – https://www.iso.org/standard/63543.html

- FMVSS 121 (49 CFR §571.121) – https://www.ecfr.gov/current/title-49/subtitle-B/chapter-V/part-571/section-571.121

- SAE J1402 (Air Brake Hose) – https://www.sae.org/standards/content/j1402_201508/

-

Fontaine No Slack II Adjustment: Enhancing Trailer Suspension Reliability & Safety

NewsNov.25,2025

-

Fontaine PDF Explained: Industrial Documentation, Specs & Innovation

NewsNov.24,2025

-

Heavy Haul Fifth Wheel – Essential Couplers for Oversized Transport

NewsNov.24,2025

-

Comprehensive Guide to Parts of the Fifth Wheel | Essential Components & Innovations

NewsNov.23,2025

-

Comprehensive Guide to 5th Wheel Parts: Key Components, Vendors & Future Trends

NewsNov.23,2025

-

Comprehensive Guide to Fifth Wheel Grease: Lubrication for Safety and Efficiency

NewsNov.22,2025