Oct . 06, 2025 07:35 Back to list

Air Suspension Series: Need Smoother Ride and Load Control?

Air Suspension Series for Trailers and Semi Trucks: Field Notes, Specs, and Real-World Lessons

If you haul for a living, you know ride quality and uptime aren’t luxuries—they’re the whole game. The Air Suspension Series from Shijiazhuang City, Hebei Province, China keeps popping up in fleet chats and buyer shortlists. To be honest, I was skeptical at first. Then I rode along on a mixed-route test—broken asphalt, dock ramps, and a windy stretch on the ring road. The difference was not subtle.

What’s shifting in the industry

Three trends are clear: fleets want lower total cost of ownership, data-backed reliability, and spec flexibility. Electrified tractors are nudging trailer builders toward lighter, lower-drag components; at the same time, shippers are asking for gentler cargo handling (hello, fragile pallets and finished goods). Air systems like the Air Suspension Series answer with adjustable ride height, consistent axle load distribution, and kinder vibration profiles.

Typical applications (with a few honest asides)

- Long-haul dry van and reefer: smoother cargo ride, fewer claims—many customers say they saw fewer ceiling scuffs.

- Container chassis and flatbeds: adjustable dock/yard interfacing.

- Tippers and tankers: improved stability under variable loads; actually noticeable in crosswinds.

- Specialty: electronics, glass, and pharma—where gentle is non-negotiable.

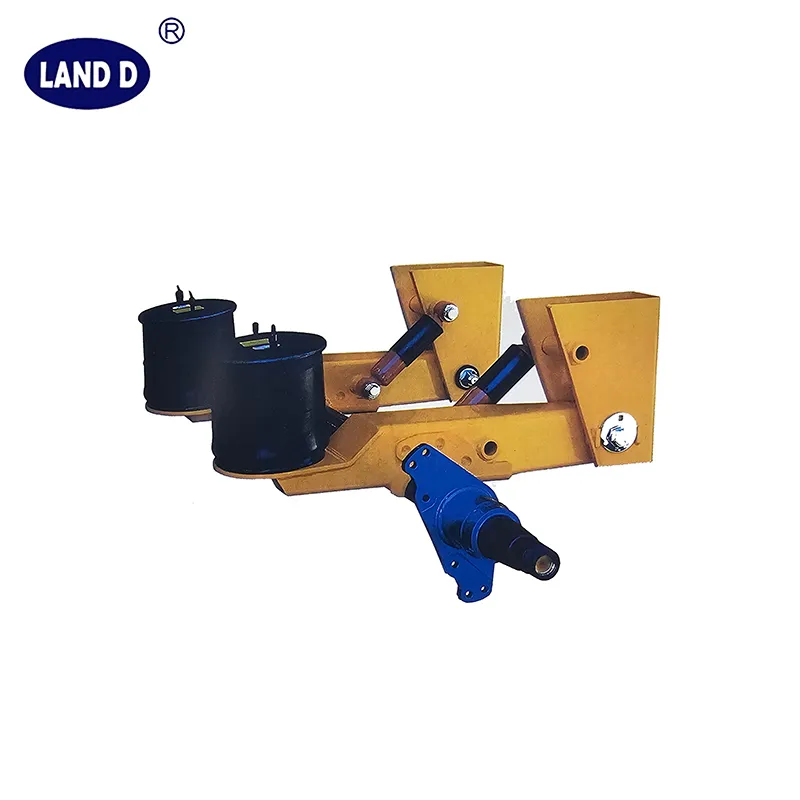

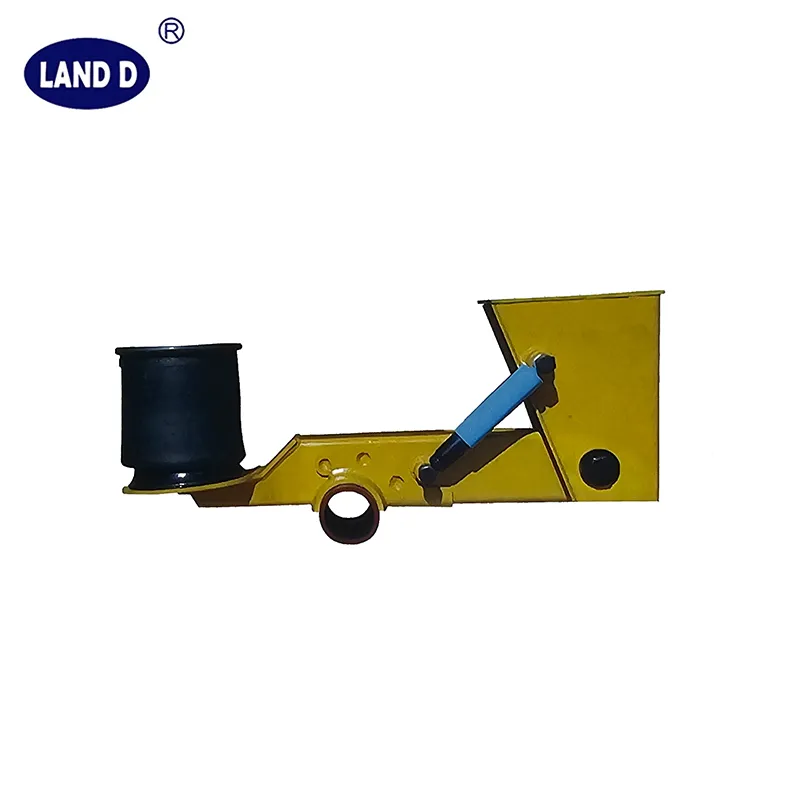

Product snapshot and core specs

| Parameter | Spec (≈ real-world) |

|---|---|

| Axle capacity per axle | ≈ 9–13 t (19,800–28,600 lb) |

| Ride height range | ≈ 180–380 mm adjustable |

| Operating temp | -40 °C to +70 °C |

| Air spring burst pressure | ≥ 24 bar (typical lab) |

| Corrosion protection | ISO 9227 salt spray ≥ 480 h |

| Service life | 1.2–1.5 million cycles (bench), field varies |

How it’s built: materials, methods, tests

Air Suspension Series uses HSLA steel hangers and torque arms, shot-peened where it matters; rubber–fabric bellows (NR/BR compound per ASTM D2000); sealed bushings with around 75–85 Shore A durometer; and zinc-flake coated fasteners.

Process flow (simplified): steel cutting → robotic welding → stress relief → surface prep + e-coat/paint → subassembly (valves, bellows) → torqueing to spec → leak test (0.2 bar/10 min, ≤ 5 cc/min) → alignment → QC sign-off.

Testing and compliance: FMVSS 121 integration checks, ISO 9227 salt spray, dynamic durability rig (≥ 1.2M cycles), dimensional audits, and traceability under ISO 9001/IATF 16949. I guess that sounds formal, but the takeaway is fewer surprises at mile 300,000.

Customization that actually matters

- Axle spacing and hanger width (OEM patterns supported).

- Ride height and valve strategy (single/dual leveling).

- Bushing hardness for lane types (rough quarry vs. interstate).

- Air spring brand options (e.g., Firestone/ContiTech equivalents).

Vendor comparison (indicative)

| Vendor | Certifications | Lead time | Notes |

|---|---|---|---|

| Land Fifth Wheel (Air Suspension Series) | ISO 9001, IATF 16949 (reported) | ≈ 3–5 weeks | Good customization, competitive on spares |

| Vendor A (global) | IATF 16949 | ≈ 6–8 weeks | Premium price; deep service network |

| Vendor B (regional) | ISO 9001 | ≈ 4–6 weeks | Budget-friendly; fewer options |

Field feedback and a quick case

A Hebei–Shenzhen reefer fleet switched 20 trailers to the Air Suspension Series. Over six months they reported ≈ 18% reduction in cargo claims and about 0.4 L/100 km fuel improvement (straighter axle alignment, less hop). It’s not a lab miracle—just steadier running.

Why it wins (most weeks)

- Ride stability and cargo protection—less vibration, fewer surprises.

- Serviceability—common valves and bellows, easy parts sourcing.

- Compliance-first mindset—built around real standards.

- Origin and support—manufactured in Shijiazhuang City, Hebei Province, China with responsive pre/post sales.

Authoritative citations

- FMVSS 121: Air Brake Systems, U.S. NHTSA.

- ISO 9001:2015 Quality Management Systems, ISO.

- IATF 16949:2016 Automotive Quality Management, IATF.

- ISO 9227: Corrosion tests in artificial atmospheres—Salt spray tests.

- ASTM D2000: Standard Classification System for Rubber Products.

- UNECE R13: Braking of categories M, N and O vehicles.

-

Fontaine No Slack II Adjustment: Enhancing Trailer Suspension Reliability & Safety

NewsNov.25,2025

-

Fontaine PDF Explained: Industrial Documentation, Specs & Innovation

NewsNov.24,2025

-

Heavy Haul Fifth Wheel – Essential Couplers for Oversized Transport

NewsNov.24,2025

-

Comprehensive Guide to Parts of the Fifth Wheel | Essential Components & Innovations

NewsNov.23,2025

-

Comprehensive Guide to 5th Wheel Parts: Key Components, Vendors & Future Trends

NewsNov.23,2025

-

Comprehensive Guide to Fifth Wheel Grease: Lubrication for Safety and Efficiency

NewsNov.22,2025