Oct . 12, 2025 09:25 Back to list

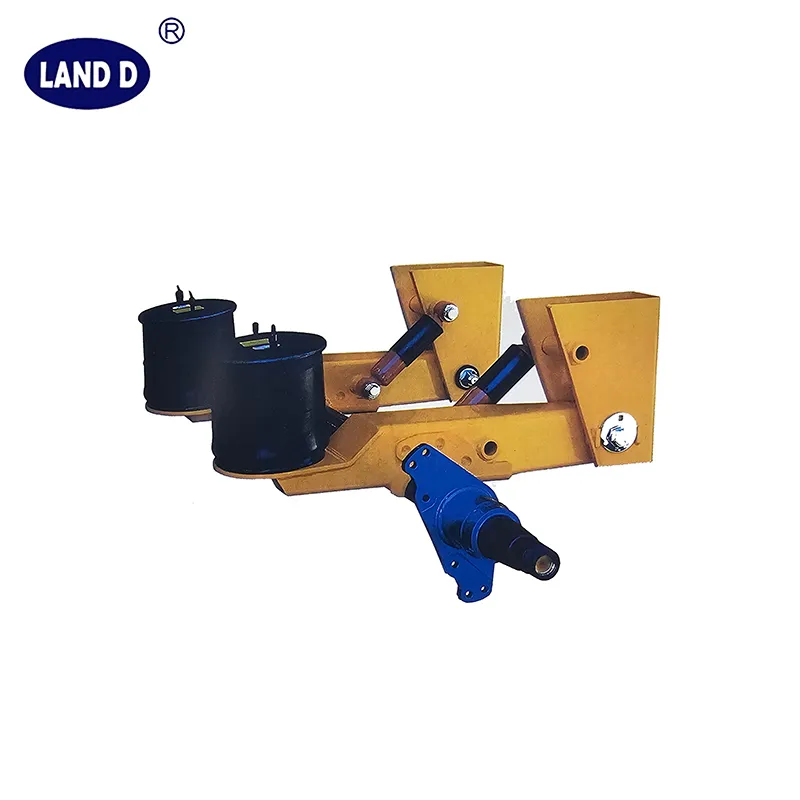

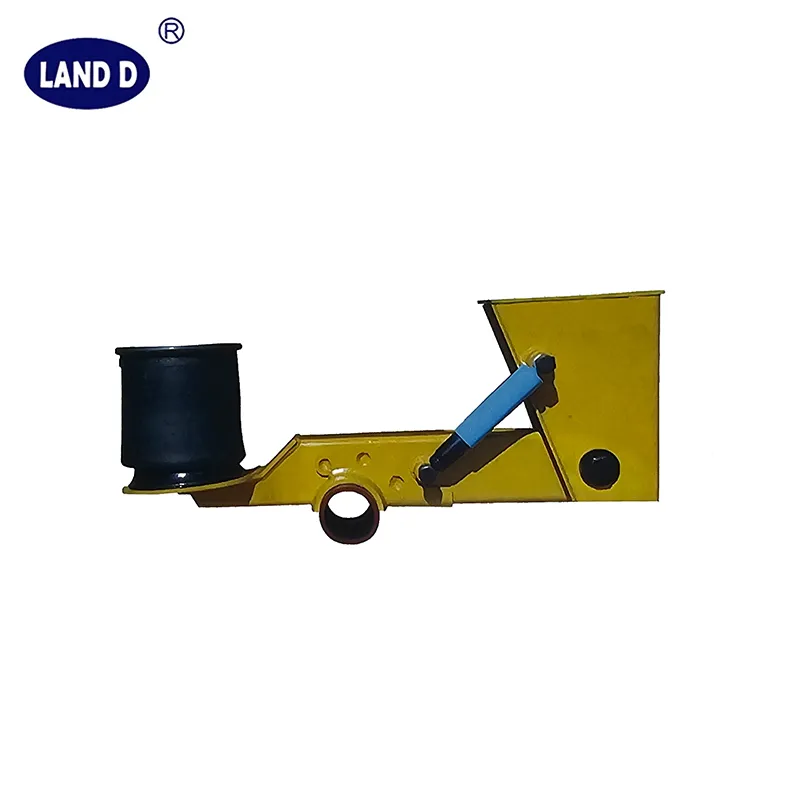

Air Suspension Series – OEM-Grade, Adjustable Ride

Air Ride Done Right: A Field Note on the Air Suspension Series

Made in Shijiazhuang City, Hebei Province, China, this trailer and semi-truck suspension set has quietly become a workhorse in long-haul fleets. I’ve seen it under tankers, low-beds, and even some mixed-duty regional rigs. Drivers tell me the ride smooths out the chatter; fleet managers say the tires finally wear evenly. Honestly, both can be true.

Industry pulse

Two big trends: lighter structures without giving up stiffness, and smarter air control. In fact, spec’ing lift axles with electronic level valves is becoming normal, even on price-sensitive builds. And, surprisingly, many customers say they’re willing to pay a bit more for anti-corrosion finishing—salted winter roads are brutal.

Key specs at a glance

| Parameter | Typical value (≈) | Notes |

|---|---|---|

| Axle load rating | 9–13 t/axle | Multi-axle configs supported |

| Ride height | ≈ 250–380 mm | Adjustable via leveling valve |

| Spring & bushing | Rubber bellows 2–3 convolute; PU/Rubber bush | Real-world use may vary by road class |

| Steel structure | Q345B, 10.9-grade fasteners | Robotic welds, jig aligned |

| Corrosion protection | ≥ 720 h NSS | ISO 9227 method |

| Operating temp | -40 ℃ to +80 ℃ | Severe-cold packs optional |

How it’s built and tested

Materials: laser-cut Q345B brackets, heat-treated hangers, shot-peened stress points. Methods: robotic MIG per AWS D1.1, e-coat base + powder top. Air bellows use multi-ply cord fabric. Validation: fatigue ≥ 1.2M cycles (SAE J2492-style), burst pressure ≥ 5× rated, salt spray per ISO 9227, and on-vehicle shakedown with ABS/EBS to ensure FMVSS 121 compliance on the braking side. Service life? Around 800,000–1,200,000 km when aligned and maintained.

Where it fits

- Long-haul box and reefer trailers needing even tire wear

- Tankers and bulkers seeking lower surge and better stability

- Low-bed/heavy-haul with lift-axle options for empty returns

- Construction and mining roads (with reinforced bushings)

Advantages I’ve noticed: quieter ride, less cargo vibration, and—this is anecdotal—fewer cracked welds around the subframe over time.

Vendor snapshot

| Criteria | Land Fifth Wheel (Air Suspension Series) | Imported Brand A | Local Assembler B |

|---|---|---|---|

| Price (per axle) | Mid, around $$ | High, $$$–$$$$ | Low–Mid, $–$$ |

| Lead time | 3–5 weeks typical | 6–10 weeks | 2–4 weeks |

| Customization depth | High (ride height, brackets, lift) | Medium | Low–Medium |

| Certifications | ISO 9001, IATF 16949 | IATF 16949 | ISO 9001 (varies) |

Customization & options

Air Suspension Series supports bolt-on lift modules, disc or drum brake brackets, hub-piloted or stud-piloted wheels, and EBS-ready plumbing. For corrosive zones, go for zinc-rich primer + topcoat. If you’re running Arctic routes, ask for low-temp elastomer spec.

Real-world notes

- Case 1 (Tanker, 3-axle): tire scrubbing down ≈18% after switching to Air Suspension Series; drivers mentioned less surge on off-ramps.

- Case 2 (Low-bed): liftable pusher saved ~4% fuel on empty backhauls; maintenance logged fewer bushing replacements over 12 months.

Customer feedback? “Set-and-forget levelling,” one fleet tech told me. Another said the alignment held better than their old steel leaf setup—no small thing.

Compliance, testing, and docs

Factory QA follows IATF 16949 routines; corrosion tests to ISO 9227; air-system interface aligned with FMVSS 121 and ECE R13 braking requirements; structural welds referenced to AWS D1.1. Test reports available on request, including fatigue curves and burst-pressure data.

If you’re speccing a new fleet, I’d pair Air Suspension Series with balanced tires and a strict alignment schedule in the first 10,000 km. It’s the cheapest insurance for ride and tire life.

Authoritative citations

- IATF 16949:2016 – Automotive Quality Management System.

- SAE J2492 – Air Spring Systems—Nomenclature, Performance, and Testing.

- ISO 9227 – Corrosion Tests in Artificial Atmospheres (Salt Spray).

- FMVSS 121 – Air Brake Systems (relevant to pneumatic integration).

- ECE R13 – Braking (EBS/ABS compatibility considerations).

-

Fontaine No Slack II Adjustment: Enhancing Trailer Suspension Reliability & Safety

NewsNov.25,2025

-

Fontaine PDF Explained: Industrial Documentation, Specs & Innovation

NewsNov.24,2025

-

Heavy Haul Fifth Wheel – Essential Couplers for Oversized Transport

NewsNov.24,2025

-

Comprehensive Guide to Parts of the Fifth Wheel | Essential Components & Innovations

NewsNov.23,2025

-

Comprehensive Guide to 5th Wheel Parts: Key Components, Vendors & Future Trends

NewsNov.23,2025

-

Comprehensive Guide to Fifth Wheel Grease: Lubrication for Safety and Efficiency

NewsNov.22,2025