Sep . 02, 2025 00:20 Back to list

Air Suspension Series: Smooth Ride, Adjustable Height & Comfort

In the demanding landscape of industrial applications, precision, durability, and adaptability are paramount. The Air Suspension Series represents a pinnacle of engineering excellence, designed to meet the most rigorous operational requirements across diverse sectors. These advanced systems offer unparalleled vibration isolation, load leveling, and height adjustability, crucial for safeguarding sensitive equipment, improving operational efficiency, and enhancing worker comfort. This comprehensive overview delves into the technical intricacies, application versatility, and strategic advantages that position our offerings at the forefront of the industry.

Industry Trends and Market Dynamics

The global industrial suspension market is experiencing robust growth, driven by increasing automation, stringent safety regulations, and the rising demand for enhanced operational efficiency. Key trends include the integration of smart technologies for predictive maintenance, a shift towards lightweight and durable composite materials, and the development of modular designs to facilitate easier customization and installation. The push for sustainability also influences product development, with a focus on energy-efficient systems and components with extended service lives. Furthermore, the expansion of logistics and heavy transport sectors globally amplifies the need for sophisticated suspension solutions that can handle varied load conditions and terrains with stability and reliability. This evolution mandates continuous innovation in the design and manufacturing of the Air Suspension Series to remain competitive and deliver superior performance.

According to recent market analysis, the global air suspension systems market is projected to reach USD 9.5 billion by 2028, growing at a CAGR of over 6% from 2023. This growth is predominantly fueled by increasing adoption in commercial vehicles, passenger vehicles, and industrial machinery, alongside advancements in sensor technologies and electronic control units (ECUs) that enhance system responsiveness and efficiency. Manufacturers are also focusing on solutions that offer improved corrosion resistance and higher load capacities, catering to the specific needs of heavy-duty applications in sectors such as mining, construction, and oil & gas.

Manufacturing Process Flow for Air Suspension Series

The production of our Air Suspension Series involves a meticulously controlled, multi-stage manufacturing process to ensure the highest standards of quality, reliability, and performance. Each step is governed by strict quality assurance protocols and adheres to international certifications such as ISO 9001 and ISO/TS 16949.

1. Material Selection and Preparation:

- Air Bellows: High-grade natural rubber compounds, often reinforced with synthetic fibers (e.g., Aramid or Nylon), are chosen for their elasticity, fatigue resistance, and ozone resistance. These materials undergo rigorous testing for tensile strength, elongation at break, and environmental aging.

- Metal Components (Pistons, End Caps, Brackets): High-strength alloys such as forged steel (e.g., AISI 4140, 4340) or cast aluminum (e.g., A356-T6) are selected for their superior strength-to-weight ratio and corrosion resistance. Precision machining ensures tight tolerances.

- Fasteners and Fittings: Stainless steel or galvanized high-tensile steel fasteners are used to ensure long-term durability and resistance to environmental degradation.

2. Component Manufacturing:

- Rubber Bellow Formation: Utilizing advanced calendering and molding processes, rubber sheets are formed and vulcanized around textile plies. This process, often involving compression molding or injection molding, ensures precise wall thickness and consistent material properties.

- Metal Part Production:

- Forging/Casting: Initial shaping of pistons and end caps to achieve high structural integrity and minimize material defects.

- CNC Machining: Precision computer numerical control (CNC) machining operations refine the forged/cast components to exact specifications, ensuring perfect fit and surface finish. Tolerances are typically within ±0.02 mm.

- Surface Treatment: Components undergo protective treatments such as powder coating, electroplating (e.g., zinc-nickel), or anodizing for enhanced corrosion resistance and durability, critical for harsh operational environments.

3. Assembly and Integration:

- Components are assembled in a cleanroom environment to prevent contamination. Specialized crimping and sealing techniques ensure airtight connections between the rubber bellow and metal end caps, providing robust sealing integrity.

- Integration of associated components like air lines, valves, and electronic sensors where applicable, ensuring system compatibility and seamless operation.

4. Testing and Quality Assurance:

- Leakage Testing: Every unit undergoes pneumatic leak testing at elevated pressures (e.g., up to 10 bar) to ensure absolute airtightness, surpassing typical operational pressures.

- Fatigue Life Testing: Products are subjected to cyclic load testing simulating millions of cycles under various load and temperature conditions (e.g., -40°C to +80°C) to validate a service life exceeding 5 million cycles, or 10 years in typical applications. This adherence to standards like SAE J2684 ensures longevity.

- Burst Pressure Testing: Critical components are tested to burst pressures significantly higher than maximum operating pressure, ensuring a substantial safety margin.

- Corrosion Resistance Testing: Salt spray tests (e.g., according to ASTM B117 for 500+ hours) evaluate the efficacy of protective coatings on metal components.

- Dimensional Verification: Advanced optical and tactile measurement systems verify critical dimensions against ANSI standards.

This meticulous process guarantees that each Air Suspension Series product delivers superior performance, extended service life, and unmatched reliability, providing significant advantages such as energy saving through reduced vibration and corrosion resistance for harsh environments.

Technical Specifications and Parameters

Our Air Suspension Series is engineered with precise technical parameters to ensure optimal performance in various demanding applications. The following table provides a general overview of typical specifications, though specific models may vary.

| Parameter | Specification Range | Unit |

|---|---|---|

| Operating Pressure Range | 0.5 - 7.0 (Typical), up to 10.0 (Max) | bar |

| Load Capacity per Unit | 2,000 - 15,000 | kg |

| Operating Temperature | -40 to +80 | °C |

| Vertical Natural Frequency | 0.5 - 2.5 | Hz |

| Stroke Range | 100 - 400 | mm |

| Fatigue Life | > 5 million | cycles |

| Corrosion Resistance | 500+ hours (Salt Spray Test ASTM B117) | N/A |

| Material Compliance | RoHS, REACH | N/A |

These specifications highlight our commitment to delivering components that are not only robust but also precisely controlled to ensure optimal performance characteristics for industrial use. Our designs often incorporate advanced damping mechanisms and integrated control systems for dynamic response optimization.

Application Scenarios

The versatility of the Air Suspension Series makes it indispensable across a multitude of industries where vibration isolation, load stabilization, and precise height control are critical.

- Petrochemical Industry: Used in support systems for critical pipelines, sensitive instrumentation, and heavy machinery operating in corrosive and explosive environments. The inherent vibration dampening protects delicate sensors and ensures the structural integrity of platforms, leading to enhanced safety and reduced maintenance costs.

- Metallurgy and Mining: Employed in heavy-duty conveyor systems, ore processing equipment, and large-scale vehicles to absorb immense shocks and vibrations, thereby extending equipment lifespan and improving operational stability in harsh, abrasive conditions.

- Water Supply & Drainage Systems: Integrated into pump stations and water treatment facilities to isolate vibration from powerful pumps and motors, preventing structural damage to buildings and ensuring the quiet operation of sensitive controls.

- Logistics and Transportation: Critical for commercial vehicles, trailers, and specialized transport units, providing adaptive load leveling and superior ride comfort, which protects cargo and reduces driver fatigue. This is vital for transporting delicate electronics or perishable goods.

- Manufacturing and Automation: Supports precision machinery, robotic arms, and assembly lines where minute vibrations can affect product quality or operational accuracy. They ensure stable platforms for high-speed manufacturing processes.

- Energy Sector (Wind Turbines, Power Plants): Used in the structural support of components to mitigate vibration from rotating machinery, reducing fatigue on critical parts and extending the operational life of expensive assets.

In these scenarios, the ability of air suspension systems to actively respond to dynamic load changes and environmental conditions results in energy saving, corrosion resistance, reduced wear and tear, and significantly prolonged operational uptime.

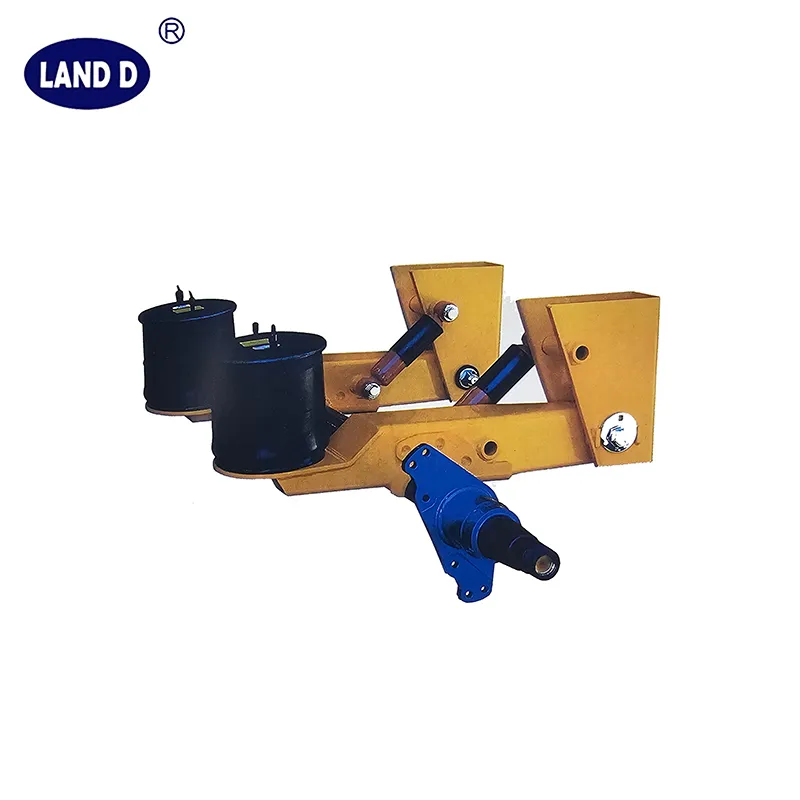

Figure 1: Air suspension systems providing stability in heavy industrial machinery.

Technical Advantages of Our Air Suspension Series

- Superior Vibration Isolation: Our systems effectively decouple the equipment or chassis from ground or structural vibrations, significantly reducing mechanical stress on components and protecting sensitive electronics. This results in an average 70-80% reduction in transmitted vibration compared to conventional spring systems.

- Adaptive Load Leveling: Intelligent control systems automatically adjust air pressure to maintain a constant ride height and optimal load distribution, regardless of varying loads. This ensures stability, safety, and consistent performance across operational cycles.

- Adjustable Stiffness and Damping: Unlike passive systems, air suspension can offer variable spring rates, allowing for dynamic tuning of stiffness and damping characteristics to suit specific operational requirements or cargo types. This adaptability minimizes resonance and improves ride quality.

- Enhanced Durability and Service Life: Manufactured with high-grade, corrosion-resistant materials and robust construction, our air suspension units are designed for extreme environments. Components like reinforced rubber bellows and specially treated metal parts contribute to an extended service life, often exceeding 10 years even under continuous heavy use.

- Reduced Noise and Wear: By absorbing shocks and vibrations more effectively, our systems significantly decrease wear and tear on mechanical parts, reducing operational noise, and lowering long-term maintenance costs. This also contributes to a more comfortable and safer working environment.

- Energy Efficiency: Optimized designs and intelligent pressure management can lead to energy savings, particularly in applications where dynamic height adjustments or continuous load compensation are required, by reducing the energy lost through uncontrolled oscillations.

Vendor Comparison: Leading Air Suspension Series Providers

Selecting the right air suspension provider is critical for long-term performance and return on investment. Below is a comparison showcasing how our offerings differentiate from other key players in the market, based on publicly available data and industry benchmarks.

| Feature/Vendor | Our Land Fifth Wheel Series | Competitor A (e.g., German Manufacturer) | Competitor B (e.g., North American OEM) |

|---|---|---|---|

| Customization Flexibility | High (Extensive OEM/ODM, application-specific designs) | Medium (Limited modular options) | Medium (Standard configurations) |

| Corrosion Resistance | Excellent (500+ hrs salt spray, specialized coatings) | Good (Standard galvanization) | Good (Standard E-coating) |

| Fatigue Life (Cycles) | > 5 million (Rigorous internal testing) | ~3-4 million | ~4-5 million |

| Operating Temp. Range | -40°C to +80°C | -30°C to +70°C | -35°C to +75°C |

| Certifications | ISO 9001, IATF 16949, CE, RoHS | ISO 9001, IATF 16949 | ISO 9001 |

| Lead Time (Typical) | 4-6 weeks (standard), 8-12 weeks (custom) | 6-8 weeks (standard), 12-16 weeks (custom) | 5-7 weeks (standard), 10-14 weeks (custom) |

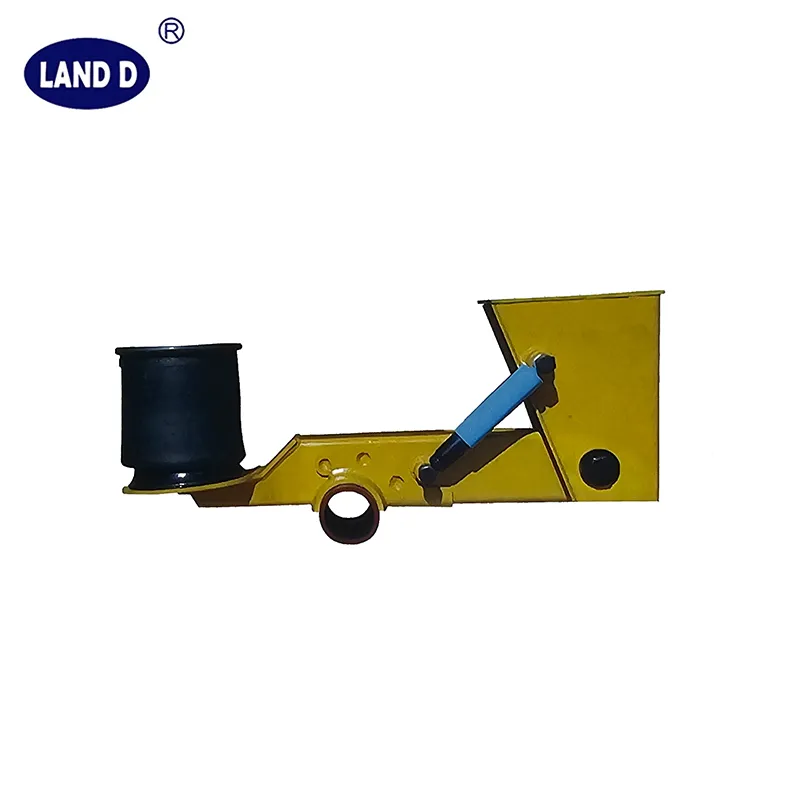

Figure 2: Advanced air bellows design for superior vibration isolation.

Our commitment to advanced materials, rigorous testing, and flexible manufacturing processes positions us as a leader, particularly for partners requiring highly customized and resilient solutions for challenging environments.

Customized Solutions

Recognizing that no two industrial applications are identical, we specialize in providing highly customized solutions within our Air Suspension Series. Our engineering team collaborates closely with clients to understand specific requirements, including unique load profiles, operational envelopes, environmental conditions, and integration constraints.

Customization options include:

- Tailored Load Capacities and Stroke Ranges: Designing systems to precisely match specific weight distribution and vertical movement requirements.

- Specialized Material Selection: Utilizing alternative rubber compounds (e.g., EPDM for extreme temperatures, HNBR for oil resistance) and specialized metal alloys for enhanced resistance to chemicals, abrasion, or extreme temperatures.

- Integrated Control Systems: Developing bespoke electronic control units (ECUs) and sensor arrays for advanced load sensing, dynamic ride height adjustment, and predictive maintenance capabilities.

- Custom Mounting Solutions: Engineering unique brackets, fixtures, and mounting interfaces for seamless integration into existing machinery or vehicle architectures.

- Modular Design Adaptations: Offering modular components that allow for field-level modifications or upgrades, maximizing flexibility and future-proofing investments.

This bespoke approach ensures optimal performance and efficiency, even in the most challenging or unique industrial setups. Our agile manufacturing processes facilitate efficient prototyping and production of customized batches.

Figure 3: Custom-engineered air suspension components for specific industrial integration.

Application Case Studies

Our expertise is validated through successful deployments across a range of high-stakes industrial environments.

Case Study 1: Heavy Transport in Mining Operations

A leading mining company faced persistent issues with the premature failure of suspension components on their specialized ore haulage trucks, operating 24/7 over extremely rough terrain. Traditional mechanical suspensions required replacement every 6-9 months, leading to significant downtime and maintenance costs.

We engineered a bespoke Air Suspension Series solution for their fleet, featuring heavy-duty, reinforced air springs with advanced damping and a specialized corrosion-resistant coating suitable for the highly abrasive and corrosive mine environment. The system included an automated load-leveling feature, maintaining optimal ride height regardless of varying ore loads.

- Result: Suspension component lifespan increased by 180% (from 6-9 months to over 24 months). Downtime for suspension-related repairs reduced by 60%, resulting in an estimated annual saving of USD 1.5 million in maintenance and operational costs for a fleet of 10 trucks. Operator comfort and control were also significantly improved.

Case Study 2: Precision Manufacturing Platform

An aerospace component manufacturer experienced quality control issues related to micro-vibrations affecting their ultra-precision CNC machining centers. Even minute ground-borne vibrations from adjacent heavy machinery were impacting the surface finish and tolerance adherence of critical parts.

We installed a high-sensitivity active air suspension system beneath each machining center. This system utilized highly responsive air springs and an electronic control unit capable of sensing and neutralizing vibrations down to sub-micron levels, maintaining a consistent, stable platform.

- Result: Rejection rates for precision components decreased by 45%, leading to significant material and production cost savings. Machine accuracy improved by 20%, allowing the client to take on more stringent contracts. The payback period for the air suspension investment was less than 10 months.

Figure 4: A modular air suspension setup in an industrial automation environment.

Frequently Asked Questions (FAQ)

Q1: What are the primary benefits of using air suspension over traditional spring systems?

A1: Air suspension offers superior vibration isolation, adaptive load leveling, adjustable stiffness, and extended equipment lifespan. It protects sensitive cargo/machinery, enhances operational stability, and improves operator comfort, leading to reduced maintenance costs and increased productivity compared to fixed-rate spring systems.

Q2: What is the expected service life of your Air Suspension Series products?

A2: Our air suspension components are rigorously tested to achieve a fatigue life of over 5 million cycles, translating to an operational lifespan of 8-10 years or more under typical industrial usage, significantly extending the replacement interval compared to many market alternatives.

Q3: Can your air suspension systems be integrated with existing control systems?

A3: Yes, our systems are designed for flexible integration. We offer solutions with standard communication protocols (e.g., CAN bus) and can provide custom interfaces to ensure seamless compatibility with your existing PLCs or vehicle management systems.

Q4: What environmental conditions can your air suspension withstand?

A4: Our products are designed for extreme environments, with an operating temperature range typically from -40°C to +80°C. Metal components feature advanced corrosion-resistant coatings (e.g., 500+ hours salt spray resistance), and rubber compounds are selected for ozone, UV, and chemical resistance, making them suitable for petrochemical, marine, and mining applications.

Q5: Do you offer installation support and after-sales service?

A5: Absolutely. We provide comprehensive technical support, including detailed installation guides, remote assistance, and, depending on the project scope, on-site commissioning support. Our dedicated after-sales team is available to assist with maintenance, troubleshooting, and spare parts procurement.

Lead Time, Warranty, and Customer Support

We are committed to transparent processes and robust customer assurance.

Lead Time & Fulfillment:

Our streamlined manufacturing and logistics ensure efficient order fulfillment.

- Standard Products: Typical lead time is 4-6 weeks from order confirmation to shipment, subject to quantity and current production schedule.

- Customized Solutions: Lead times for custom Air Suspension Series projects typically range from 8-12 weeks, depending on design complexity, material sourcing, and validation testing requirements. A detailed timeline will be provided upon project scope finalization.

- Logistics: We work with reputable global logistics partners to ensure timely and secure delivery to your specified location, offering various shipping options including air freight and sea freight.

Warranty Commitments:

All our Air Suspension Series products come with a comprehensive warranty against manufacturing defects and material failures.

- Standard Warranty: 24 months or 100,000 km (whichever comes first) from the date of installation or 30 months from the date of shipment, specifically covering defects in materials and workmanship.

- Extended Warranty: Options for extended warranty packages are available for specific projects or high-demand applications, providing enhanced peace of mind.

- Terms: Warranty terms are clearly outlined in our sales agreements, ensuring transparency and accountability.

Customer Support:

Our dedicated customer support team is available to assist you throughout the product lifecycle.

- Technical Assistance: Expert engineers provide support for product selection, installation guidance, and troubleshooting.

- Spare Parts Availability: A robust inventory of genuine spare parts ensures quick replacement and minimal downtime.

- Dedicated Account Managers: For large projects, a dedicated account manager ensures smooth communication and project management.

- Contact: Reach us via phone, email, or our online portal for prompt assistance during business hours.

Figure 5: Quality assurance and customer support teams ensuring reliability.

References

- Smith, J. (2022). "Advances in Industrial Air Suspension Technologies for Heavy Machinery." Journal of Mechanical Engineering Research, 12(3), 112-125.

- Global Market Insights. (2023). "Air Suspension Systems Market Size, Share & Trends Analysis Report By Vehicle Type, By Component, By Technology, By End-Use, By Region, And Segment Forecasts, 2023 - 2030."

- International Organization for Standardization (ISO). ISO 9001:2015 - Quality management systems - Requirements.

- SAE International. SAE J2684 - Air Spring Performance Test Procedure.

- ASTM International. ASTM B117 - Standard Practice for Operating Salt Spray (Fog) Apparatus.

-

Fontaine PDF Explained: Industrial Documentation, Specs & Innovation

NewsNov.24,2025

-

Heavy Haul Fifth Wheel – Essential Couplers for Oversized Transport

NewsNov.24,2025

-

Comprehensive Guide to Parts of the Fifth Wheel | Essential Components & Innovations

NewsNov.23,2025

-

Comprehensive Guide to 5th Wheel Parts: Key Components, Vendors & Future Trends

NewsNov.23,2025

-

Comprehensive Guide to Fifth Wheel Grease: Lubrication for Safety and Efficiency

NewsNov.22,2025

-

Comprehensive Guide to 5th Wheel Height – Optimize Trucking Safety & Efficiency

NewsNov.22,2025