Nov . 07, 2025 10:40 Back to list

American Type Welding Series Suspension for Heavy Trailers

American Type Welding Series Suspension: field notes from the shop floor

If you’ve spent time around heavy trailers, you’ve seen the American Type Welding Series Suspension geometry a thousand times: stout hangers, leaf packs, torque rods, and honest steel doing hard miles. To be honest, the category hasn’t “gone viral,” but it keeps freight on schedule. Built in Shijiazhuang City, Hebei Province, CHINA, this line has been showing up on flatbeds, tankers, and bulk haulers that care more about uptime than flash.

What’s trending (and why it matters)

Industry trend lines point to thicker hanger plates, better bushings, and more rigorous weld QA. Actually, fleets tell me they’re prioritizing predictable lifecycle over ultra-lighting everything. There’s also a quiet shift toward traceable steel (A572-grade equivalence) and documented WPS/PQR per AWS D1.1—because audits are real, and insurance underwriters read reports now.

Quick specs that operators ask me about

| Parameter | Typical value (≈ / may vary) |

|---|---|

| Axle load rating | 9–13 t per axle (tandem/tridem options) |

| Steel grade | Q345B ≈ ASTM A572 Gr.50 for hangers/crossmembers |

| Welding process | GMAW (MIG/MAG), ER70S-6 wire, per AWS D1.1 WPS |

| Bushing type | Oil-less composite or rubber-in-metal; greaseable pins optional |

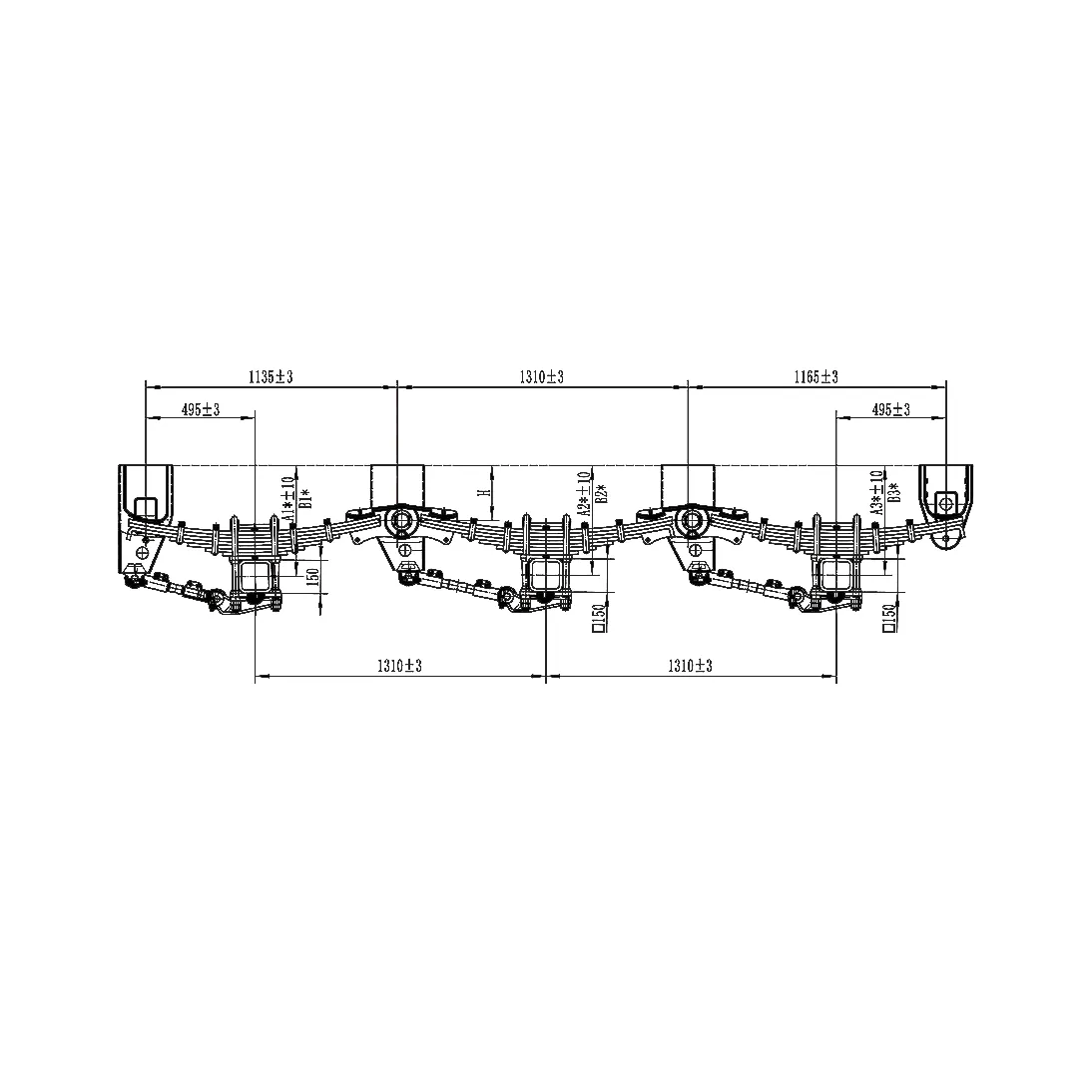

| Track width / hanger spacing | ≈ 1840–2040 mm / 381–420 mm (custom on request) |

| Corrosion protection | Shot blast SA 2.5 + epoxy or powder coat; 480 h ISO 9227 salt spray tested |

| Service life | Often 8–10 years in highway use; off-road fleets report ≈ 5–7 |

Process flow, testing, and paperwork (the unglamorous bits)

Materials arrive with mill certs. Hangers and brackets are CNC cut, fixtured, then GMAW welded; fillet sizes are gauged and macro-etched by sample lot. MT is applied at high-stress toes; UT audits run quarterly on representative joints. Bolted joints get torque witness marks. Coatings are checked for DFT; corrosion validation follows ISO 9227. Welders are qualified to AWS D1.1; filler is ER70S-6. It sounds dry—but this is what keeps leaf eyes from cracking at 400,000 km.

Where it’s being used

- Flatbeds and drop-decks chasing long highway lanes.

- Tanker, silo, and bulk trailers where stability beats softness.

- Construction and logging routes—rougher, but still doable.

Advantages? Straightforward maintenance, predictable alignment, parts that most regional shops stock. Many customers say the American Type Welding Series Suspension “just feels honest”—not my words, but I get the sentiment.

Customization menu

Track width, hanger spacing, spring rate/leaf count, torque rod style, spindle/hub patterns (10×285.75, 8×275), and coating systems. Fleet paint codes? Sure. I guess the surprise is how fast changeovers can be when fixtures are modular.

Vendor landscape (my shorthand)

| Vendor | Certs | Steel traceability | Testing | Lead time | Price band |

|---|---|---|---|---|---|

| LAND (Shijiazhuang) | ISO 9001, IATF 16949 | Heat/lot linked to MTCs | MT, macro-etch, salt-spray | ≈ 3–6 weeks | Mid |

| Generic import | Varies | Partial | Visual only (often) | ≈ 6–10 weeks | Low |

| Local fab shop | Shop-specific | Good but limited lots | Depends on request | ≈ 1–3 weeks | Mid–High |

Field data and a quick case

One Midwest fleet swapped in American Type Welding Series Suspension tandems on 40 flatbeds. After 18 months: bushing wear down 22%, alignment resets halved, and no hanger cracks (MT spot checks, 2 per trailer). Real-world use may vary, but that’s not nothing.

Customer feedback: “Stable under mixed loads,” says a tanker operator; “paint holds up past two winters,” notes a Quebec flatbed owner. I’m inclined to agree after seeing the salt-spray results and weld bead consistency.

Compliance checkpoints

- Welding per AWS D1.1; ER70S-6 filler per AWS A5.18.

- Base steel equivalent to ASTM A572/A36 where specified.

- Coating durability screened with ISO 9227 salt spray.

- Quality systems: ISO 9001; automotive-grade IATF 16949 for process control.

Authoritative citations

-

Fontaine PDF Explained: Industrial Documentation, Specs & Innovation

NewsNov.24,2025

-

Heavy Haul Fifth Wheel – Essential Couplers for Oversized Transport

NewsNov.24,2025

-

Comprehensive Guide to Parts of the Fifth Wheel | Essential Components & Innovations

NewsNov.23,2025

-

Comprehensive Guide to 5th Wheel Parts: Key Components, Vendors & Future Trends

NewsNov.23,2025

-

Comprehensive Guide to Fifth Wheel Grease: Lubrication for Safety and Efficiency

NewsNov.22,2025

-

Comprehensive Guide to 5th Wheel Height – Optimize Trucking Safety & Efficiency

NewsNov.22,2025