Oct . 31, 2025 00:25 Back to list

American Type Welding Series Suspension | Heavy-Duty, Stable

American Type Welding Series Suspension is a key solution in the manufacturing industry, specifically within Special Equipment Manufacturing Industry and Manufacturing of welding and cutting equipment. This article explores how Shijiazhuang Land Auto Component Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- American Type Welding Series Suspension Overview

- Benefits & Use Cases of American Type Welding Series Suspension in Manufacturing of welding and cutting equipment

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on American Type Welding Series Suspension from Shijiazhuang Land Auto Component Ltd.

American Type Welding Series Suspension Overview

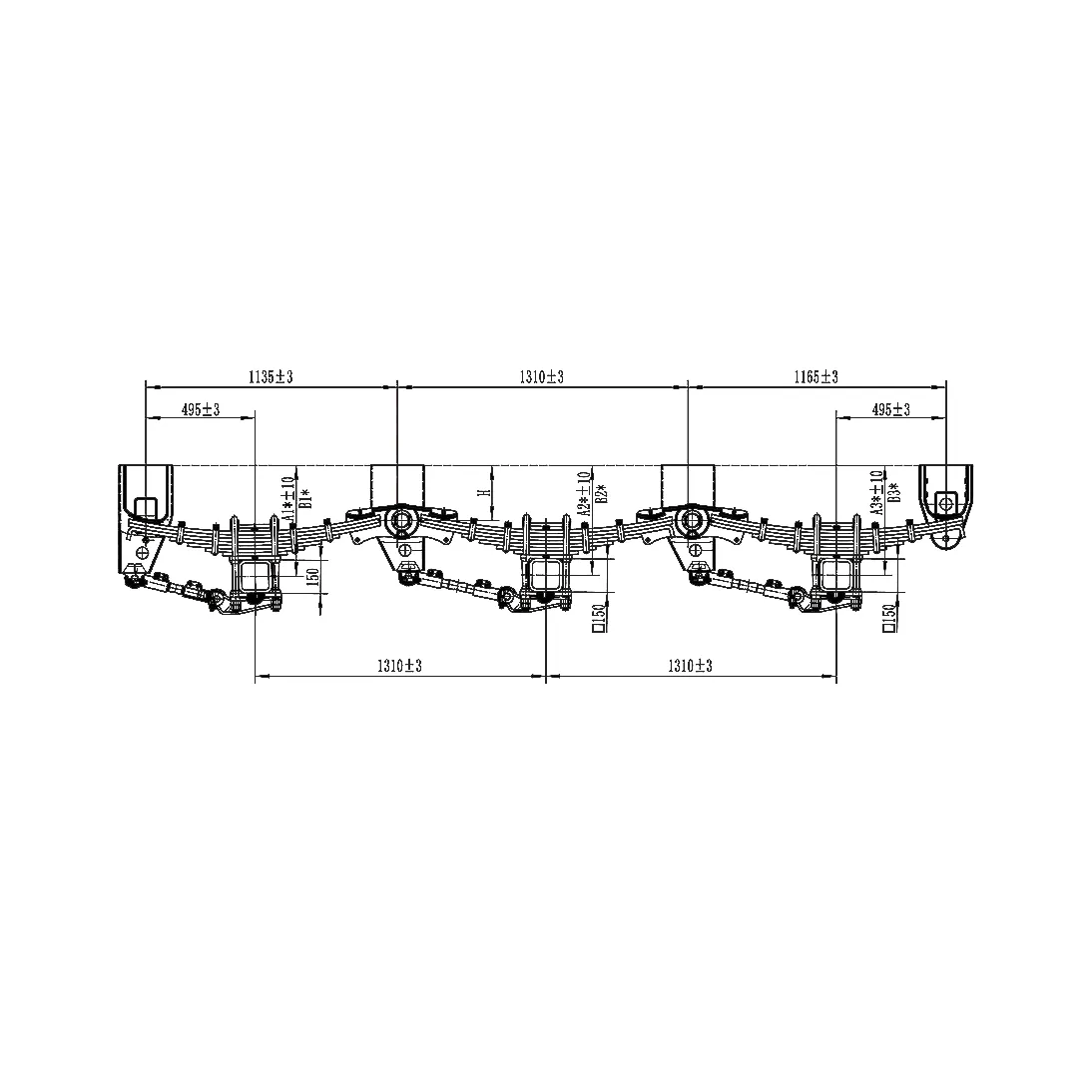

The American Type Welding Series Suspension is a heavy-duty, welded trailer suspension assembly engineered for reliability under demanding loads and routes. Built around robust hangers, equalizers, torque rods, and axle seats, it stabilizes axle alignment, distributes weight evenly, and minimizes vibration—critical for transporting precision welding and cutting equipment. In B2B environments where uptime and safe equipment transport are non-negotiable, this suspension configuration offers predictable performance and easier maintenance compared with more complex systems.

Technically, buyers look for high-strength steel hangers, precision-jig welding for consistent geometry, heat-treated pins, and durable bushings (rubber or polyurethane) with accessible greasing points. Typical options include multiple axle capacities, ride heights, and axle seat diameters to match common American-spec axles. Shijiazhuang Land Auto Component Ltd. manufactures the American Type Welding Series Suspension with an emphasis on dimensional accuracy, part interchangeability, and coating protection—helping fleets standardize across multiple trailers while reducing installation time and post-install alignment adjustments.

Benefits & Use Cases of American Type Welding Series Suspension in Manufacturing of welding and cutting equipment

Manufacturers of welding and cutting equipment often move delicate power sources, wire feeders, automated welding cells, and high-value laser/plasma systems between plants, test bays, and customer sites. The American Type Welding Series Suspension provides a stable, low-vibration platform for semi-trailers, equipment carriers, and service trailers—protecting sensitive electronics and alignment-critical assemblies during transport. For in-plant logistics, its predictable axle tracking helps reduce tire scrub and improves handling around tight corners and loading docks.

- Applications: delivery trailers for welding systems, gas bundle carriers, steel plate logistics, mobile fabrication units, and maintenance service fleets.

- Competitive advantages: rugged welded construction, adjustable torque rods for precise axle alignment, long-life bushings, and American-standard component compatibility for easy sourcing.

- Shijiazhuang Land Auto Component Ltd.’s expertise: deep manufacturing know-how in heavy-duty trailer components, with attention to consistent weld quality, fit-up precision, and finish durability.

Cost, Maintenance & User Experience

Total cost of ownership in fleet operations hinges on predictable maintenance, parts availability, and asset longevity. The American Type Welding Series Suspension is designed with common wear items—bushings, pins, and equalizers—that are easy to inspect and replace. Welded hanger geometry maintains axle spacing and camber over time, helping reduce tire wear and alignment-related downtime. For B2B buyers managing multiple locations or contractors, the ability to standardize on a single suspension platform simplifies inventory and training, improving ROI across the equipment lifecycle.

- Durability and ROI: high-strength steel sections and robust welds support long service life; straightforward design reduces unexpected failure points and service hours.

- Maintenance experience: fleets value accessible grease points, clear visual inspection of bushings and fasteners, and quick alignment adjustments via torque rods—minimizing time off the road.

Customers in the Special Equipment Manufacturing Industry appreciate that this suspension behaves consistently across load cases, from light demo units to fully crated cutting machines. Feedback often centers on smoother ride quality, better axle tracking under braking, and reduced service variability—key benefits when transporting precision welding and cutting assets.

Sustainability & Market Trends in manufacturing

Sustainability in industrial transport increasingly emphasizes durability, reparability, and material efficiency. Choosing a long-life suspension like the American Type Welding Series Suspension reduces replacement frequency and waste. Design elements such as modular wear parts, recyclable steel components, and protective coatings that extend service life align with environmental targets and reduce total embodied carbon across a trailer’s lifecycle. As regulatory pressure grows on logistics and heavy industry, equipment buyers favor components that balance performance with maintainability and resource efficiency.

- Market trends: increased demand for reliable transport of high-value fabrication equipment, more stringent uptime metrics, and preference for standardized, widely supported suspension platforms.

- Shijiazhuang Land Auto Component Ltd. positions itself as forward-thinking by focusing on robust materials, consistent weld quality, and designs that support refurbishment—helping customers extend asset life while meeting operational and sustainability goals.

Conclusion on American Type Welding Series Suspension from Shijiazhuang Land Auto Component Ltd.

For B2B decision-makers in the Special Equipment Manufacturing Industry and the Manufacturing of welding and cutting equipment, the American Type Welding Series Suspension delivers the reliability, stability, and maintainability needed to move critical assets safely and efficiently. Its rugged, American-standard design, supported by Shijiazhuang Land Auto Component Ltd.’s manufacturing expertise, helps fleets reduce downtime, simplify parts management, and protect high-value equipment in transit.

- Count on proven value and consistent performance in demanding manufacturing logistics.

- Backed by Shijiazhuang Land Auto Component Ltd.’s commitment to quality and customer support.

- Strong CTA: Contact us: email: info@land-d.cn — Visit our website: https://www.landfifthwheel.com

-

Fontaine No Slack II Adjustment: Enhancing Trailer Suspension Reliability & Safety

NewsNov.25,2025

-

Fontaine PDF Explained: Industrial Documentation, Specs & Innovation

NewsNov.24,2025

-

Heavy Haul Fifth Wheel – Essential Couplers for Oversized Transport

NewsNov.24,2025

-

Comprehensive Guide to Parts of the Fifth Wheel | Essential Components & Innovations

NewsNov.23,2025

-

Comprehensive Guide to 5th Wheel Parts: Key Components, Vendors & Future Trends

NewsNov.23,2025

-

Comprehensive Guide to Fifth Wheel Grease: Lubrication for Safety and Efficiency

NewsNov.22,2025