Oct . 03, 2025 11:00 Back to list

American Type Welding Series Suspension - Heavy-Duty Value?

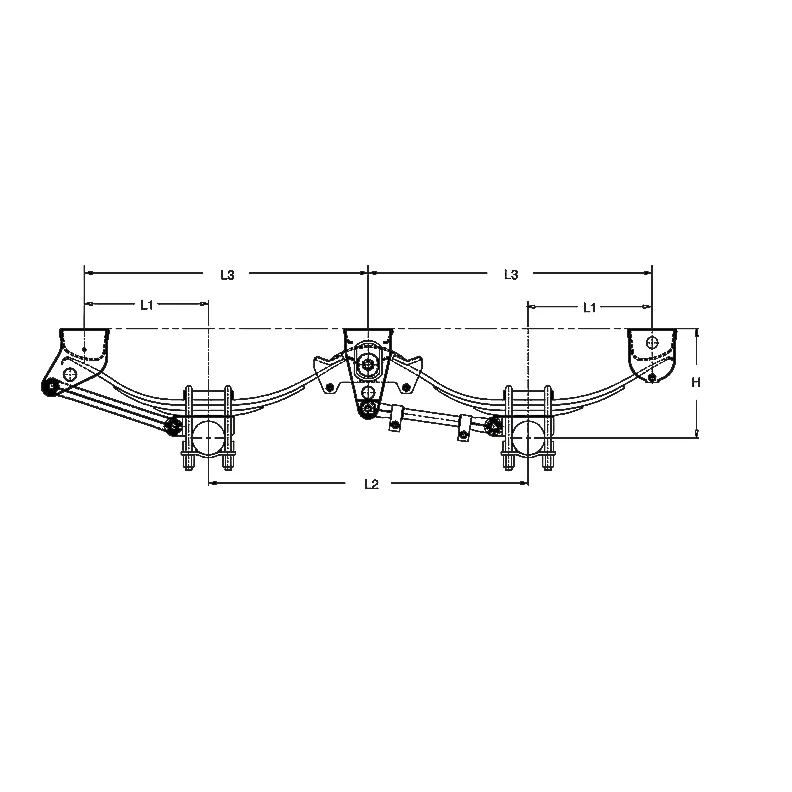

Field Notes on the American Type Welding Series Suspension

I’ve been poking around semi-trailer yards for years, and—honestly—hardware tells on itself. Welds, bushings, and hangers either hold alignment or they don’t. The American Type Welding Series Suspension has been popping up more in fleets that care about uptime, which made me curious: what’s driving the adoption, and is it just spec-sheet bragging or real-road proof?

What’s Trending in Trailer Suspensions

Two things: weld quality consistency (robot-assisted or very disciplined fixtures) and corrosion defense. Fleets tell me they’re tired of hanger ear distortion and bolt hole ovalization after a couple of seasons. The American Type Welding Series Suspension, built in Shijiazhuang City, Hebei Province, China, leans into thicker hangers, tighter jigs, and coatings that actually survive winter routes.

Product Snapshot

| Parameter | Typical Value | Notes |

|---|---|---|

| Axle capacity (per axle) | ≈ 10–13 t | Tandem or tri-axle options; real-world use may vary |

| Hanger/Bracket steel | Q345/ASTM A572 Gr.50 | 8–12 mm typical thickness |

| Weld process | MIG/MAG (GMAW) | AWS D1.1-compliant procedures |

| Leaf springs | Multi-leaf 75Cr1/60Si2Mn | Heat-treated; shot-peened |

| Bushing options | Natural rubber or PU (Shore A 75–90) | Greaseable pins optional |

| Finish | Zinc-rich primer + topcoat | ≈ 480–720 h ISO 9227 salt spray |

| Service life | 5–8 years typical | Up to 10 with preventive maintenance |

How It’s Built (and Verified)

Materials: high-strength low-alloy steels (A572/Q345) and ER70S-6 filler. Methods: GMAW with jigs to keep bracket geometry true—this matters more than the brochure admits. Testing: weld macros, MT spot checks, and fatigue on a road-simulation rig (≥ 1.2 million cycles target). Corrosion tests follow ISO 9227; welding procedures align to AWS D1.1; environmental per SAE J1455 where applicable. I’ve seen shop sheets showing bushing compression set under 20% after 72 h at 70°C—respectable.

Where It Fits

- Highway semi-trailers: flatbed, drop deck, van, reefer

- Container chassis and tankers (with appropriate axle spacing)

- Construction and ag trailers—when operators want rugged, not flashy

- Mining haul roads (with polyurethane bushings and reinforced hangers)

Vendor Landscape (quick take)

| Aspect | Land (Shijiazhuang, Hebei) | Vendor X | Vendor Y |

|---|---|---|---|

| Lead time | ≈ 3–5 weeks | 4–6 weeks | 6–8 weeks |

| Warranty | 18–24 months | 12 months | 12–18 months |

| Certifications | ISO 9001; AWS D1.1 procedures | ISO 9001 | ISO 9001; CE (where relevant) |

| Customization | High (track, ride height, bushings) | Medium | Medium–High |

| Test data access | Shared on request | Limited | Summary only |

Customization Menu

Pick your poison: axle spacing, hanger height (for deck/kingpin targets), spring count, rubber vs PU bushings, track width, and coating system. Many customers say the rubber bushing spec is fine for highway, but fleets on gravel go PU—less squirm, a touch harsher ride.

Mini Case Files

- Regional flatbed fleet (Midwest): reported 0.3° average axle misalignment drift after 9 months—better than their previous spec by about half, they claim.

- Grain hauler: switched to PU bushings; cut bushing swaps by ≈ 30% season-over-season. Ride got slightly firmer (drivers noticed, but accepted).

Compliance and Notes

Welding per AWS D1.1 procedures, material certs available, and salt spray tested per ISO 9227. If your trailer spec touches FMVSS 121 (braking) integration, coordinate axle/brake suppliers—suspension geometry affects brake balance, indirectly. It seems obvious, but I’ve seen it ignored.

Bottom line: the American Type Welding Series Suspension isn’t flashy, but the weld discipline and thicker hangers pay off in alignment stability and bushing life. To be honest, that’s what matters on year three.

Authoritative References

- AWS D1.1/D1.1M: Structural Welding Code—Steel, American Welding Society. https://pubs.aws.org

- ISO 9227: Corrosion tests in artificial atmospheres—Salt spray tests. https://www.iso.org/standard/63543.html

- SAE J1455: Recommended Environmental Practices for Electronic Equipment Design in Heavy-Duty Vehicle Applications. https://www.sae.org

- ASTM A572/A572M: Standard Specification for High-Strength Low-Alloy Columbium-Vanadium Structural Steel. https://www.astm.org

-

Fontaine No Slack II Adjustment: Enhancing Trailer Suspension Reliability & Safety

NewsNov.25,2025

-

Fontaine PDF Explained: Industrial Documentation, Specs & Innovation

NewsNov.24,2025

-

Heavy Haul Fifth Wheel – Essential Couplers for Oversized Transport

NewsNov.24,2025

-

Comprehensive Guide to Parts of the Fifth Wheel | Essential Components & Innovations

NewsNov.23,2025

-

Comprehensive Guide to 5th Wheel Parts: Key Components, Vendors & Future Trends

NewsNov.23,2025

-

Comprehensive Guide to Fifth Wheel Grease: Lubrication for Safety and Efficiency

NewsNov.22,2025