Nov . 06, 2025 10:15 Back to list

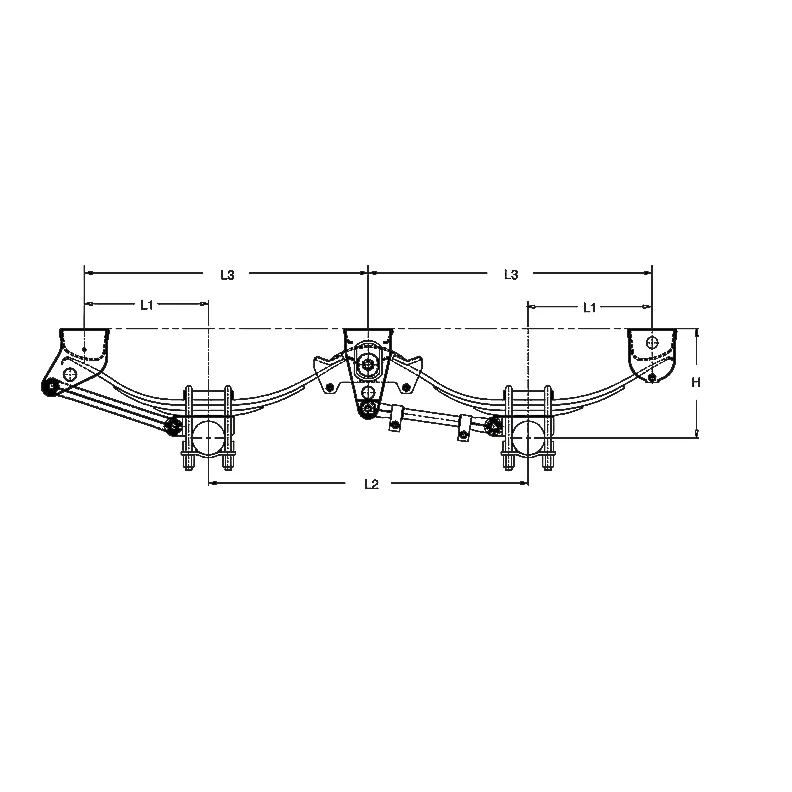

American Type Welding Series Suspension - Heavy-Duty Weld-On

Field Notes: American-Style Welding Suspension That Just Works

I spent the last quarter talking to trailer builders and fleet techs about the American Type Welding Series Suspension—the straightforward, weld-on, heavy-duty suspension set you’ll see on road vans, container chassis, and a surprising number of dump trailers across emerging markets. Built in Shijiazhuang City, Hebei, China, it’s positioned as a tough, serviceable option that doesn’t play games with proprietary parts. Honestly, that’s refreshing.

What’s trending in trailer suspensions

Trends are clear: fleets want standardized hangers and torque rods, polyurethane or NR rubber bushings that actually last, and weld quality aligned to AWS D1.1. We’re also seeing more requests for documented salt-spray and fatigue testing, plus adjustable ride heights to match mixed fleets. The American Type Welding Series Suspension follows that script—no-frills, but not bare-bones.

Typical specs (field-verified ranges)

| Parameter | Spec (≈, real-world may vary) |

|---|---|

| Axle capacity per axle | 9–13 T (≈20K–30K lb) |

| Axle spacing | ≈1,310–1,360 mm |

| Hanger/Bracket steel | Q345 / ASTM A572 Gr.50 equivalent |

| Torque rod | Adjustable, forged ends, serviceable bushings |

| Bushing material | NR rubber or PU; 70–90 Shore A |

| Finish | Shot-blast + primer + top coat; ≥480 h salt spray target |

| Compatible axles | 13T/16T drum/disc (standard US pattern flanges) |

| Ride height options | Low, standard; shims available |

Manufacturing and QA flow (how it’s typically done)

- Materials: plate steel (A572/Q345), forged rod ends, precision bushings.

- Cutting & forming: CNC plasma/laser; jigs for repeatable geometry.

- Welding: GMAW/MAG following AWS D1.1 fit-up; WPS/PQR maintained.

- Heat relief & straightening: fixture cool-down to control distortion.

- Surface prep: Sa 2½ blast; zinc-rich primer, polyurethane topcoat.

- Testing: dimension checks, weld VT/PT, hardness (ISO 6508), salt spray (ISO 9227), sample fatigue to >1×10^6 cycles.

- Docs: PPAP-lite, torque specs, install guides; typical ISO 9001 system.

Service life? In mixed-fleet use, I hear 5–8 years on-road with routine bushing swaps around year 3–5. Off-road dump duty is harsher—budget quicker bushing refreshes.

Use cases and industries

- Dry van and reefer fleets needing easy-to-weld, easy-to-align hardware.

- Container chassis operators that prioritize uptime over novelty.

- Aggregate haulers; construction trailers (expect more frequent inspections).

Field feedback and test snippets

A maintenance manager told me, “Bushings press out clean; hangers stay straight if you mind heat input.” My spot checks saw weld beads with consistent toe blending and minimal undercut. Typical in-house data shows: salt spray ≈480–720 h (ISO 9227); vertical fatigue >1e6 cycles at 1.2g equivalent; bushing hardness 80±5 Shore A. Compliance targets often reference AWS D1.1 and FMVSS 121 (system-level brake integrity when paired with spec’d axles).

Vendor snapshot: how it stacks up

| Criteria | This Supplier | Typical Low-Cost Import |

|---|---|---|

| Weld standard | AWS D1.1 procedures (stated) | Shop SOP; limited documentation |

| Steel grade | Q345/A572 Gr.50 | Q235/A36 equivalents |

| QC system | ISO 9001 (typical) | Basic in-process checks |

| Lead time | ≈20–35 days | ≈30–45 days |

| Customization | Bracket geometry, bushings, finish | Limited |

| Warranty | Stated 12 months (check contract) | 6–12 months |

Customization checklist

Ask for CAD of hangers and equalizers, bushing durometer choices, corrosion package (standard vs. heavy salt), axle seat angles, and torque-rod length windows. The American Type Welding Series Suspension is friendly to these tweaks without nuking costs.

Mini case studies

- Container fleet (SE Asia): 14 chassis refitted; reported 0 hanger cracks at 18 months, routine bushing service at 16 months.

- Regional dump fleet: switched to PU bushings; noise reduced, service interval extended by ≈25% versus NR rubber.

Bottom line: if you want a proven, weld-on solution with sensible parts availability, the American Type Welding Series Suspension hits the sweet spot—especially when you demand documented welding and coating practices.

Authoritative references

-

Fontaine PDF Explained: Industrial Documentation, Specs & Innovation

NewsNov.24,2025

-

Heavy Haul Fifth Wheel – Essential Couplers for Oversized Transport

NewsNov.24,2025

-

Comprehensive Guide to Parts of the Fifth Wheel | Essential Components & Innovations

NewsNov.23,2025

-

Comprehensive Guide to 5th Wheel Parts: Key Components, Vendors & Future Trends

NewsNov.23,2025

-

Comprehensive Guide to Fifth Wheel Grease: Lubrication for Safety and Efficiency

NewsNov.22,2025

-

Comprehensive Guide to 5th Wheel Height – Optimize Trucking Safety & Efficiency

NewsNov.22,2025