Jan . 06, 2025 18:48 Back to list

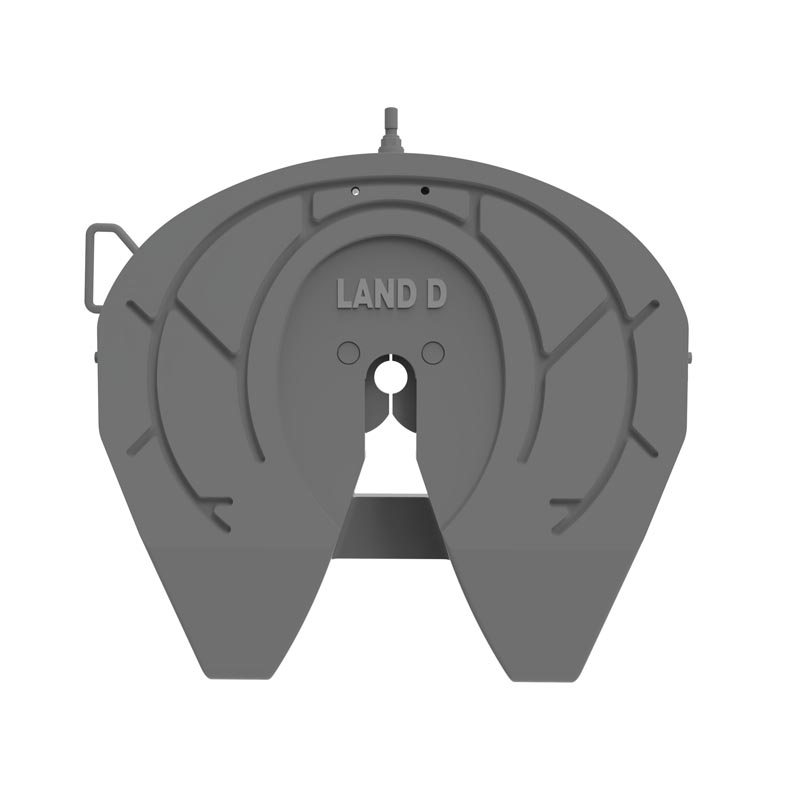

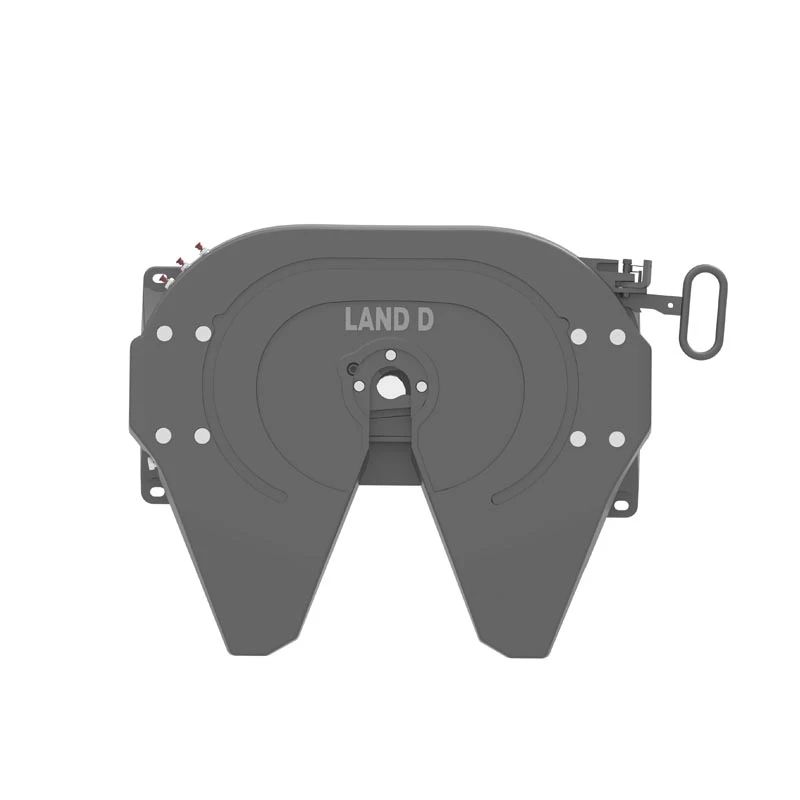

5th wheel bumper kit

Fifth wheel couplings represent a pivotal component in modern transport solutions, especially for industries reliant on heavy-duty towing. As seasoned professionals will attest, the correct selection and maintenance of these couplings can mean the difference between seamless operations and incessant logistical delays.

With decades of evolution, fifth wheel couplings have transformed from rudimentary connectors into highly sophisticated devices, integrating technology for safety and efficiency. As an expert in transport systems, it's clear that the modern coupling's design is about precision engineering to handle immense weights while ensuring safety and longevity.

Real-world experiences often highlight the critical role of regular inspections in maintaining these couplings. Case studies from leading logistics companies reveal that routine maintenance checks not only extend the lifespan of the couplings but also enhance safety on the highways. One such study noted a 30% increase in operational efficiency after implementing a stringent maintenance regime, underscoring the need for regular professional oversight.

Fifth wheel couplings must meet rigorous international safety standards, and as an authority in the field, the involvement in standard-setting processes underscores the importance of innovations like advanced locking mechanisms and improved lubrication systems. Recent advancements have introduced self-lubricating technologies, reducing manual maintenance needs and improving coupling performance even under extreme conditions.

fifth wheel couplings

In the realm of expertise, understanding the varieties of couplings—be it the traditional single plate or the more advanced automatic locking variants—allows for tailored applications across different fleet needs. Insights from industry veterans suggest that matching the correct coupling to the specific requirements of a truck and trailer combination is paramount. This is where the consultation with manufacturers who provide detailed technical support and customization options becomes invaluable.

Trust in fifth wheel couplings is built through proven performance and reliability. Testimonials from truck operators often highlight the peace of mind that comes with using products from leading manufacturers known for their rigorous testing procedures and robust designs. Operators trust brands with a history of quality and safety, often advocating for those that offer comprehensive after-sales support and training services.

Finally, experience has shown that integrating smart technologies into couplings—such as IoT sensors for monitoring wear and load stress—can prevent accidents and costly downtime. This futuristic approach is not merely theoretical but has been effectively implemented by early adopters in the industry, showcasing improved logistical predictions and asset management.

In summation, fifth wheel couplings are more than just parts of a truck—they are critical components demanding expert knowledge and meticulous care to ensure the success of transportation operations. With the right blend of experience, expertise, authoritative support, and trustworthiness, businesses can harness the full potential of these essential transport devices.

-

Hexagonal Wire Mesh - Shijiazhuang Land Auto Component Ltd. | Durable, Corrosion-Resistant, Versatile

NewsAug.10,2025

-

Hexagonal Wire Mesh-Shijiazhuang Land Auto Component Ltd.|Corrosion Resistance, Customization

NewsAug.10,2025

-

Semi Trailer Kingpin Plate Replacement - Durable Parts

NewsAug.10,2025

-

Hexagonal Wire Mesh - Shijiazhuang Land Auto Component Ltd.|Versatile Industrial Solution&Corrosion Resistant Material

NewsAug.09,2025

-

Hexagonal Wire Mesh - Shijiazhuang Land Auto Component Ltd. | Corrosion Resistance, Custom Solutions

NewsAug.09,2025

-

Hexagonal Wire Mesh - Shijiazhuang Land Auto Component Ltd.|Corrosion Resistance&Tensile Strength

NewsAug.09,2025