Jan . 15, 2025 01:49 Back to list

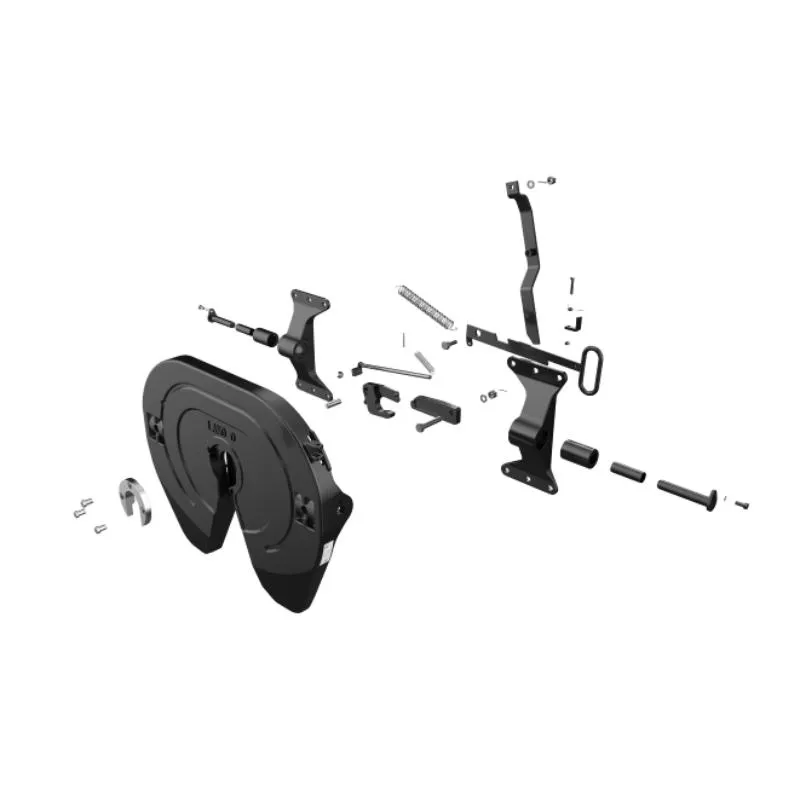

fifth wheel coupling system

When it comes to the intricate mechanics of towing heavy trailers, the fifth wheel coupling system stands as a pivotal innovation in the industry. This system embodies the perfect blend of engineering precision and practical functionality, serving both novice drivers and seasoned professionals in their hauling endeavors.

Trustworthiness is another critical factor when discussing fifth wheel coupling systems. Reliable systems are designed with safety features such as locking mechanisms and indicator lights that confirm successful coupling. Regular inspections and routine maintenance checks are essential practices to instill confidence and trust in these systems. Drivers and fleet managers should establish a regimen that includes checking for wear and tear, ensuring all bolts and pins are secure, and verifying the integrity of the locking system. From a product-oriented perspective, investing in a fifth wheel coupling system involves considering the latest technological advancements. For instance, some systems now integrate smart sensors that monitor the coupling status and provide real-time alerts to the driver’s dashboard, offering an added layer of safety and reassurance. Ultimately, the fifth wheel coupling system is not just a mechanical implement but a cornerstone of trailer and load management. Its design and functionality have evolved considerably, making it an indispensable tool for those involved in heavy-duty transport. By understanding the operational principles and maintaining rigorous selection and maintenance standards, professionals can harness the full potential of this system, ensuring enhanced performance, safety, and longevity. Embracing innovation while adhering to established standards will invariably set a high benchmark in the field of towing and transport logistics, paving the way for safer and more efficient roadways.

Trustworthiness is another critical factor when discussing fifth wheel coupling systems. Reliable systems are designed with safety features such as locking mechanisms and indicator lights that confirm successful coupling. Regular inspections and routine maintenance checks are essential practices to instill confidence and trust in these systems. Drivers and fleet managers should establish a regimen that includes checking for wear and tear, ensuring all bolts and pins are secure, and verifying the integrity of the locking system. From a product-oriented perspective, investing in a fifth wheel coupling system involves considering the latest technological advancements. For instance, some systems now integrate smart sensors that monitor the coupling status and provide real-time alerts to the driver’s dashboard, offering an added layer of safety and reassurance. Ultimately, the fifth wheel coupling system is not just a mechanical implement but a cornerstone of trailer and load management. Its design and functionality have evolved considerably, making it an indispensable tool for those involved in heavy-duty transport. By understanding the operational principles and maintaining rigorous selection and maintenance standards, professionals can harness the full potential of this system, ensuring enhanced performance, safety, and longevity. Embracing innovation while adhering to established standards will invariably set a high benchmark in the field of towing and transport logistics, paving the way for safer and more efficient roadways.

Previous:

Latest news

-

Nuss Truck Sauk Rapids - High Quality, Best Deals & Discounts Available

NewsJul.08,2025

-

High Quality Kingpin Adalah – Best Kingpin Adalah for Trucks, Get Discount Kingpin Adalah Now!

NewsJul.08,2025

-

High Quality Fifth Wheel Bracket for Heavy Loads – Best Discount Deals Online

NewsJul.08,2025

-

High Quality Fifth Wheel Coupling System for Trucks Best Fifth Wheel Coupling System Online

NewsJul.07,2025

-

High Quality & Best Volvo Trucks in Kansas City Discount Volvo Trucks for Sale

NewsJul.07,2025

-

High Quality & Best Standard Height of Tractor Trailer – Discount Prices Available

NewsJul.07,2025