Dec . 19, 2024 15:35 Back to list

king pin plate assembly factories

The Importance of King Pin Plate Assembly in Vehicle Safety

In the intricate world of automotive engineering and manufacturing, every component plays a crucial role in ensuring vehicle safety and performance. Among these components, the king pin plate assembly stands out as a vital element, particularly in heavy-duty vehicles such as trucks and buses. Understanding the manufacturing processes and quality standards associated with king pin plate assemblies is essential for ensuring the reliability and safety of these vehicles.

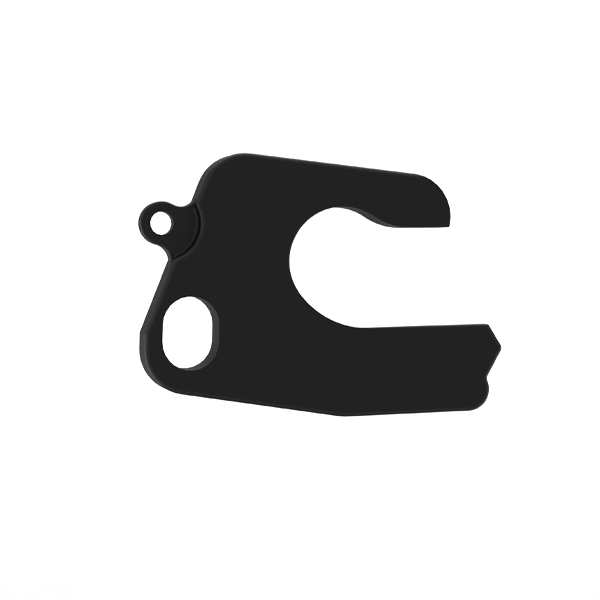

What is a King Pin Plate Assembly?

The king pin plate assembly is a critical component of a vehicle's steering system, specifically in front axle setups. It connects the steering knuckles to the axle and allows for smooth pivoting during turns. The assembly consists of several parts, including the king pins, bearings, bushings, and the plate itself. This assembly ensures that the load is evenly distributed, contributing to better control and maneuverability of the vehicle.

Manufacturing Process of King Pin Plate Assemblies

The manufacturing of king pin plate assemblies involves several sophisticated steps to ensure precision and quality. Factories specializing in automotive components use advanced machinery and techniques, such as CNC (Computer Numerical Control) machining, to create the various parts of the assembly.

1. Material Selection High-quality materials, such as high-strength steel, are selected to withstand the heavy loads and stresses associated with vehicle operation. The chosen materials must also offer resistance to wear and corrosion.

2. Machining and Fabrication The selected materials undergo precise machining processes, ensuring that each component is manufactured to exact specifications. Tolerance levels are critical during this step to guarantee seamless integration into the vehicle's system.

3. Heat Treatment To enhance the durability and strength of the components, a heat treatment process is often employed. This process involves heating the metal parts to a specific temperature and then cooling them rapidly, which improves their overall mechanical properties.

king pin plate assembly factories

4. Quality Control After production, each king pin plate assembly undergoes rigorous quality control checks. This includes visual inspections, dimensional checks, and sometimes even advanced tests such as ultrasonic or magnetic particle inspections to detect any internal flaws.

5. Assembly The final step in the manufacturing process is the assembly of all components. Technicians or automated systems carefully put together the king pins, bearings, bushings, and plates, ensuring that each part fits perfectly and meets safety standards.

Ensuring Safety Through Standards

Safety is paramount in the automotive industry, and factories producing king pin plate assemblies must adhere to strict quality assurance standards. Organizations such as the International Organization for Standardization (ISO) define quality management systems essential for manufacturing processes. Compliance with such standards not only enhances product quality but also boosts consumer confidence in the manufacturer's commitment to safety.

The Role of Innovation in King Pin Assembly Manufacturing

As technology evolves, so too does the manufacturing of king pin plate assemblies. Factories are increasingly adopting automation and robotics to improve efficiency and reduce human error. Furthermore, innovations in materials science are leading to the development of lighter yet stronger materials that can enhance the performance of king pin assemblies.

Conclusion

In conclusion, the king pin plate assembly is an integral part of vehicle safety and performance, especially in heavy-duty applications. The manufacturing process—marked by rigorous quality controls and innovations—ensures that these components can withstand the rigors of the road while maintaining safe and reliable operation. Understanding the importance of king pin plate assemblies not only highlights their role in vehicle dynamics but also underscores the commitment of manufacturers to delivering high-quality automotive components. As the industry continues to advance, the focus on safety, reliability, and innovation will remain at the forefront of king pin plate assembly production.

-

Nuss Truck Sauk Rapids - High Quality, Best Deals & Discounts Available

NewsJul.08,2025

-

High Quality Kingpin Adalah – Best Kingpin Adalah for Trucks, Get Discount Kingpin Adalah Now!

NewsJul.08,2025

-

High Quality Fifth Wheel Bracket for Heavy Loads – Best Discount Deals Online

NewsJul.08,2025

-

High Quality Fifth Wheel Coupling System for Trucks Best Fifth Wheel Coupling System Online

NewsJul.07,2025

-

High Quality & Best Volvo Trucks in Kansas City Discount Volvo Trucks for Sale

NewsJul.07,2025

-

High Quality & Best Standard Height of Tractor Trailer – Discount Prices Available

NewsJul.07,2025