ਜੂਨ . 12, 2025 09:43 ਸੂਚੀ 'ਤੇ ਵਾਪਸ ਜਾਓ

Unveiling the Core Elements of Fifth Wheel Technology

In the realm of heavy - duty transportation, the fifth wheel plays a pivotal role as the critical interface between tractors and semi - trailers. Central to this connection are concepts such as the fifth wheel mechanism, fifth wheel coupling system, fifth wheel coupling device, ਅਤੇ fifth wheel coupling design. These components work in harmony to ensure secure, efficient, and reliable load transfer, enabling the seamless operation of commercial trucking fleets across various terrains and under diverse conditions. Understanding the intricacies of these elements is essential for optimizing vehicle performance, enhancing safety, and prolonging the lifespan of heavy - hauling equipment.

The Intricate Functioning of the Fifth Wheel Mechanism

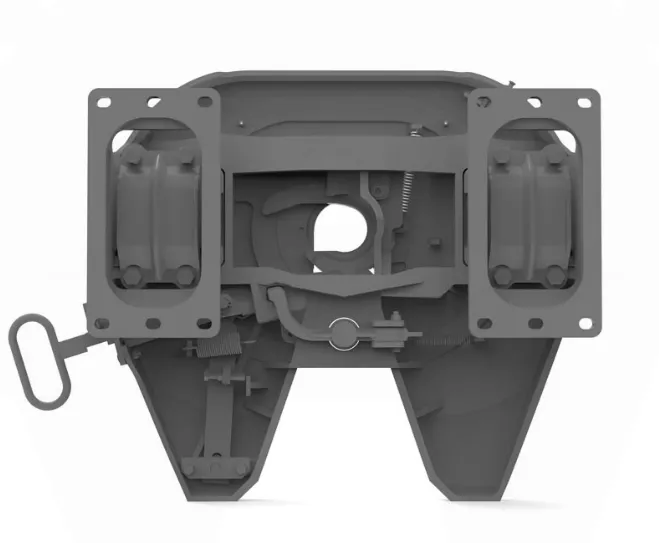

At the heart of the tractor - trailer connection lies the fifth wheel mechanism, a complex assembly designed to withstand substantial forces while facilitating smooth maneuvering. This mechanism typically consists of a top plate, locking jaws, and a release system. During operation, the fifth wheel mechanism engages with the kingpin on the trailer, distributing the weight of the load evenly between the tractor and the trailer. For example, in long - distance hauling, the fifth wheel mechanism allows the trailer to pivot freely during turns, ensuring that the vehicle can navigate sharp corners and narrow roads without compromising stability. High - quality fifth wheel mechanisms are engineered with precision - crafted components, such as hardened steel jaws, to resist wear and tear and maintain a secure connection over extended periods of use.

The Comprehensive Nature of the Fifth Wheel Coupling System

The fifth wheel coupling system encompasses not only the physical components of the fifth wheel but also the processes and procedures involved in connecting and disconnecting trailers. This system includes elements like the coupling mechanism, alignment aids, and safety features. Modern fifth wheel coupling systems often incorporate advanced technologies, such as automatic locking mechanisms and sensor - based monitoring systems. These enhancements improve the efficiency of the coupling process and enhance safety by providing real - time feedback on the connection status. For instance, some fifth wheel coupling systems are equipped with indicators that alert operators when the trailer is not properly coupled, reducing the risk of accidents caused by loose connections. The seamless integration of these components within the fifth wheel coupling system ensures that the tractor - trailer combination can operate safely and effectively in a variety of environments.

The Design and Function of Fifth Wheel Coupling Devices

Fifth wheel coupling devices are the physical structures that enable the connection between tractors and trailers. These devices come in various designs, each tailored to specific applications and load requirements. Traditional fifth wheel coupling devices are typically made of robust materials, such as cast iron or steel, to withstand the rigors of heavy - duty transportation. Newer designs may incorporate lightweight yet durable materials, like aluminum alloys, to reduce vehicle weight and improve fuel efficiency. The shape and size of fifth wheel coupling devices also play a crucial role in their performance. For example, low - profile designs can lower the center of gravity of the tractor - trailer combination, enhancing stability during high - speed travel. Additionally, some fifth wheel coupling devices feature adjustable components, allowing operators to fine - tune the connection based on the type of trailer and the nature of the load being transported.

Innovations in Fifth Wheel Coupling Design

Fifth wheel coupling design has evolved significantly over the years, driven by advancements in materials science, engineering, and safety standards. Modern designs focus on improving ease of use, reliability, and durability. One notable innovation is the development of self - aligning fifth wheel coupling designs, which simplify the coupling process by automatically guiding the kingpin into the correct position. Another trend is the integration of smart technologies, such as Bluetooth - enabled sensors, into fifth wheel coupling designs. These sensors can monitor parameters like coupling force, wear, and temperature, providing valuable data for predictive maintenance and ensuring the longevity of the coupling system. Furthermore, ergonomic considerations have become increasingly important in fifth wheel coupling design, with manufacturers creating more user - friendly release mechanisms and control interfaces to reduce operator fatigue and improve overall efficiency.

FAQ Regarding Fifth Wheel Components

Key Factors in Selecting a Fifth Wheel Coupling Device

When choosing a fifth wheel coupling device, several factors should be considered. First, assess the weight and type of loads you typically transport, as this will determine the required capacity and strength of the device. Consider the operating environment, including terrain, climate, and road conditions, as these factors can impact the durability and performance of the coupling device. Additionally, evaluate the ease of use, maintenance requirements, and compatibility with your existing tractor and trailer fleet. Look for devices that meet or exceed industry safety standards and come with reliable warranties to ensure long - term reliability and peace of mind.

Maintenance Tips for Fifth Wheel Mechanisms

Regular maintenance is essential for keeping fifth wheel mechanisms in optimal condition. Routinely inspect the coupling components for signs of wear, such as cracks, excessive play, or damaged locking jaws. Lubricate moving parts, such as the release mechanism and pivot points, according to the manufacturer's recommendations to prevent friction and premature wear. Clean the fifth wheel surface regularly to remove dirt, debris, and corrosive substances that can damage the components. Check the alignment of the fifth wheel and kingpin during each coupling and uncoupling operation to ensure a secure connection. By following these maintenance practices, you can extend the lifespan of your fifth wheel mechanism and minimize the risk of breakdowns and accidents.

Impact of Fifth Wheel Coupling Design on Fuel Efficiency

The design of the fifth wheel coupling can have a significant impact on fuel efficiency. Lightweight designs, such as those made from aluminum alloys, reduce the overall weight of the vehicle, requiring less energy to move. Aerodynamic fifth wheel coupling designs can also minimize air resistance, further improving fuel economy. Additionally, efficient coupling systems that reduce friction and ensure smooth operation can contribute to better fuel efficiency. By choosing a fifth wheel coupling design that prioritizes weight reduction, aerodynamics, and smooth operation, operators can potentially save on fuel costs over the long term.

Safety Features to Look for in Fifth Wheel Coupling Systems

Safety is paramount when it comes to fifth wheel coupling systems. Look for systems that feature automatic locking mechanisms, which provide a more secure connection compared to manual systems. Sensor - based monitoring systems, such as those that detect improper coupling or excessive wear, can enhance safety by alerting operators to potential issues. Other important safety features include anti - rattle devices, which reduce noise and vibration during travel, and high - visibility indicators that make it easier to check the coupling status. Ensure that the fifth wheel coupling system you choose meets or exceeds all relevant safety standards and regulations to protect both operators and other road users.

Compatibility of Fifth Wheel Components with Different Trailer Types

Not all fifth wheel components are compatible with every type of trailer. It's crucial to ensure that the fifth wheel mechanism, coupling device, and other components are designed to work with the specific kingpin size, height, and weight capacity of your trailer. Different trailer manufacturers may also have specific requirements or recommendations for fifth wheel compatibility. Before purchasing or installing any fifth wheel components, consult the trailer's owner's manual or contact the manufacturer to confirm compatibility. This will help prevent issues such as improper coupling, uneven load distribution, and potential damage to the tractor or trailer.

-

Why Are Specialized Components Crucial in Commercial Vehicle Maintenance and Operation?

ਖ਼ਬਰਾਂJul.28,2025

-

Why Are Fifth Wheels Critical for Trucking and How to Select the Right One?

ਖ਼ਬਰਾਂJul.28,2025

-

What Defines the Excellence of American Trailer Components in Key Markets?

ਖ਼ਬਰਾਂJul.28,2025

-

What Defines the Excellence of American 5th Wheel Systems and Their Market Offerings?

ਖ਼ਬਰਾਂJul.28,2025

-

How Do 5th Wheel Trailers Redefine Towing and Living Standards?

ਖ਼ਬਰਾਂJul.28,2025

-

How Do 5th Wheel Systems Enhance Commercial Hauling Efficiency and Versatility?

ਖ਼ਬਰਾਂJul.28,2025