Feb . 13, 2025 04:09 Back to list

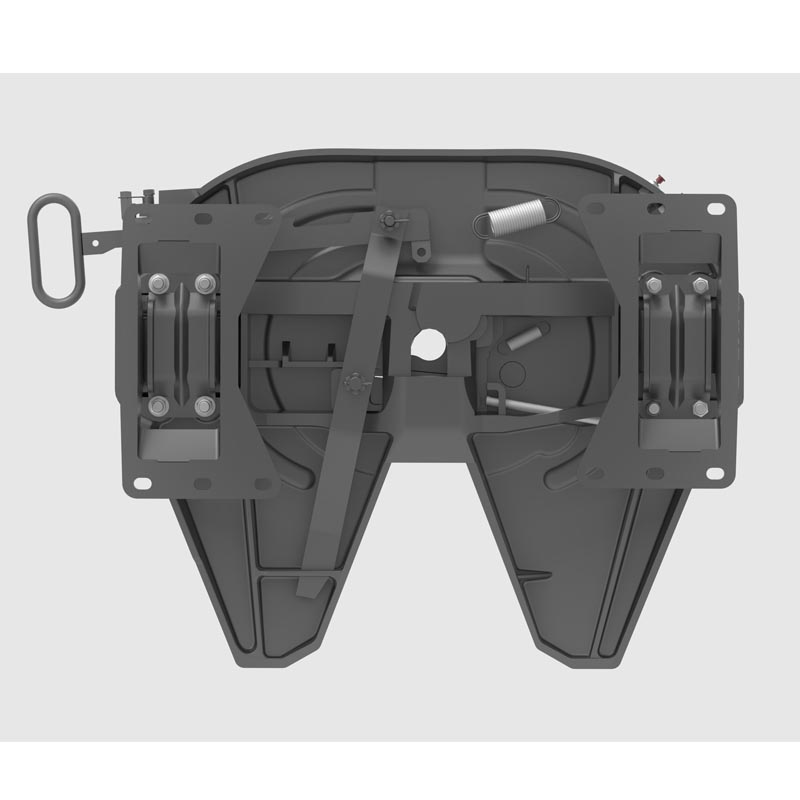

High Quality JOST tape Fifth wheel J3800 repair kits

In recent years, the industrial and automotive sectors have increasingly embraced the value of lube inserts. These components, while seemingly simple, play a pivotal role in ensuring machinery and vehicles operate smoothly, efficiently, and with reduced wear and tear. Understanding the intricacies and advantages of lube inserts can position you as an informed stakeholder in any mechanical field.

Furthermore, leveraging authoritative insights from industry leaders and technical literature can deepen one’s knowledge about advanced lube insert technologies. Many leading manufacturers conduct extensive research and testing to develop inserts that meet evolving demands. For example, the development of self-lubricating inserts represents a significant advancement. These inserts gradually release lubricants during operation, negating the necessity for manual reapplication, which further cuts down on maintenance time and costs. Trustworthiness is another essential factor when selecting a supplier for lube inserts. It is advisable to partner with reputable manufacturers who have a proven track record for quality and reliability. Companies that offer thorough product guarantees or extended warranties can provide additional peace of mind. Moreover, product reviews and testimonials can provide valuable insights into real-world performance and customer satisfaction. It's crucial to remember that while lube inserts present numerous advantages, their effectiveness is maximized when paired with routine maintenance and inspections. Regular checks help to ensure that inserts remain intact and functioning optimally, and any signs of wear are addressed promptly. This proactive approach helps in maintaining operational efficiency and can further augment the benefits that lube inserts inherently provide. In conclusion, by embracing the use of lube inserts, businesses can achieve substantial improvements in operational efficiency, cost-effectiveness, and machinery longevity. The key lies in understanding the distinct needs of your equipment, selecting the right inserts, and collaborating with reputable manufacturers. As industries continue to evolve, staying informed about the latest developments in lube insert technology ensures that you are well-positioned to maintain a competitive edge in your field.

Furthermore, leveraging authoritative insights from industry leaders and technical literature can deepen one’s knowledge about advanced lube insert technologies. Many leading manufacturers conduct extensive research and testing to develop inserts that meet evolving demands. For example, the development of self-lubricating inserts represents a significant advancement. These inserts gradually release lubricants during operation, negating the necessity for manual reapplication, which further cuts down on maintenance time and costs. Trustworthiness is another essential factor when selecting a supplier for lube inserts. It is advisable to partner with reputable manufacturers who have a proven track record for quality and reliability. Companies that offer thorough product guarantees or extended warranties can provide additional peace of mind. Moreover, product reviews and testimonials can provide valuable insights into real-world performance and customer satisfaction. It's crucial to remember that while lube inserts present numerous advantages, their effectiveness is maximized when paired with routine maintenance and inspections. Regular checks help to ensure that inserts remain intact and functioning optimally, and any signs of wear are addressed promptly. This proactive approach helps in maintaining operational efficiency and can further augment the benefits that lube inserts inherently provide. In conclusion, by embracing the use of lube inserts, businesses can achieve substantial improvements in operational efficiency, cost-effectiveness, and machinery longevity. The key lies in understanding the distinct needs of your equipment, selecting the right inserts, and collaborating with reputable manufacturers. As industries continue to evolve, staying informed about the latest developments in lube insert technology ensures that you are well-positioned to maintain a competitive edge in your field.

Latest news

-

Extreme Fifth Wheels Premium Durability & Off-Road Performance

NewsMay.12,2025

-

Best Deals on Volvo & Mack Trucks Southwest El Paso, TX

NewsMay.12,2025

-

Hubbard Auto Sales Boaz AL Quality Cars & Discount Prices

NewsMay.11,2025

-

5th Wheel Kingpins - Best Discounts, Sizes & Heavy-Duty Designs

NewsMay.11,2025

-

High-Quality Fontaine Trailer Parts Near Me Best Deals & Local Pickup

NewsMay.11,2025

-

High-Quality Wheel Equipment Inc Durable & Cost-Effective Solutions

NewsMay.10,2025