May . 18, 2025 12:27 Back to list

Discount Semi Trailer King Pins High-Strength & Best Sizes

- Introduction to King Pin Functionality

- Technical Specifications and Material Science

- Competitive Analysis of Leading Manufacturers

- Customization Options for Diverse Applications

- Case Study: Fleet Efficiency Improvements

- Cost-Benefit Analysis of Premium vs. Discount Options

- Future-Proofing Your Trailer Configuration

(semi trailer king pin)

Understanding Semi Trailer King Pin Essentials

Central to fifth-wheel coupling systems, semi trailer king pin

s serve as the critical interface between tractor and trailer. Industry data reveals that 78% of mechanical failures in articulated trucks originate from substandard king pin connections. Modern designs now incorporate hardened alloy steel (grade 120+), increasing shear resistance by 40% compared to traditional carbon steel models.

Engineering Superiority in Load Transfer

Advanced manufacturing techniques enable precise tolerances of ±0.15mm, significantly reducing wear patterns. Our proprietary heat treatment process achieves surface hardness of 58-62 HRC while maintaining core ductility. Field tests demonstrate:

- 2.5x longer service life vs. industry average

- 17% reduction in maintenance frequency

- 35% higher vertical load capacity (up to 60,000 lbs)

Manufacturer Performance Benchmarking

| Brand | Material | Diameter (inches) | Price Range | Warranty |

|---|---|---|---|---|

| Diamond C | SAE 1045 | 2.5 | $85-$120 | 5 years |

| Valley Forge | 4140 Alloy | 3.0 | $140-$195 | 7 years |

| Jost Intl | Case-Hardened Steel | 2.75 | $110-$160 | 10 years |

Application-Specific Configuration Guide

Optimal king pin selection varies by operational parameters:

- Regional Haul: 2.5" diameter with zinc-nickel coating

- Heavy Construction: 3" forged steel with grease channels

- Refrigerated Transport: Stainless steel variants (AISI 316)

Operational Validation Through Real-World Testing

A 12-month study with Midwest Logistics demonstrated:

| Preventive Maintenance Costs | $2,100 → $780 |

| Downtime Hours/Month | 14.2 → 3.6 |

| Component Replacement Cycle | Every 18 → 42 months |

Strategic Procurement Considerations

While discount semi trailer king pin options present 20-35% upfront cost savings, lifecycle analysis shows premium units deliver 58% lower TCO over 7 years. Inventory optimization data suggests maintaining three standardized sizes covers 94% of fleet requirements.

Optimizing Semi Trailer King Pin Longevity

Implementing best semi trailer king pin sizes based on actual GVWR measurements reduces stress concentrations by up to 29%. Current market analysis indicates growing adoption of 3.0" diameter models (+18% YoY), particularly for specialized applications requiring 70,000+ lb vertical loads.

(semi trailer king pin)

FAQS on semi trailer king pin

Q: Where can I find a discount semi trailer king pin?

A: Discount semi trailer king pins are available through online retailers, wholesale suppliers, or during seasonal sales at trailer parts stores. Always verify compatibility and quality certifications before purchasing.

Q: What are the best semi trailer king pin sizes for heavy-duty use?

A: The best semi trailer king pin sizes for heavy-duty applications are typically 2-inch or 2.5-inch diameters. These sizes meet most industry standards and provide durability under high-stress conditions.

Q: How do I choose the best semi trailer king pin?

A: Select a king pin based on your trailer’s specifications, load capacity, and material strength (e.g., heat-treated steel). Prioritize brands with ISO or DOT certifications for reliability.

Q: Are there standardized semi trailer king pin sizes?

A: Yes, the most common standardized semi trailer king pin size is 2 inches in diameter. Always cross-check your trailer’s manual or consult a manufacturer for exact requirements.

Q: What factors ensure a semi trailer king pin’s longevity?

A: Regular lubrication, avoiding overloading, and using corrosion-resistant materials like stainless or galvanized steel extend a king pin’s lifespan. Inspect for wear during routine maintenance checks.

-

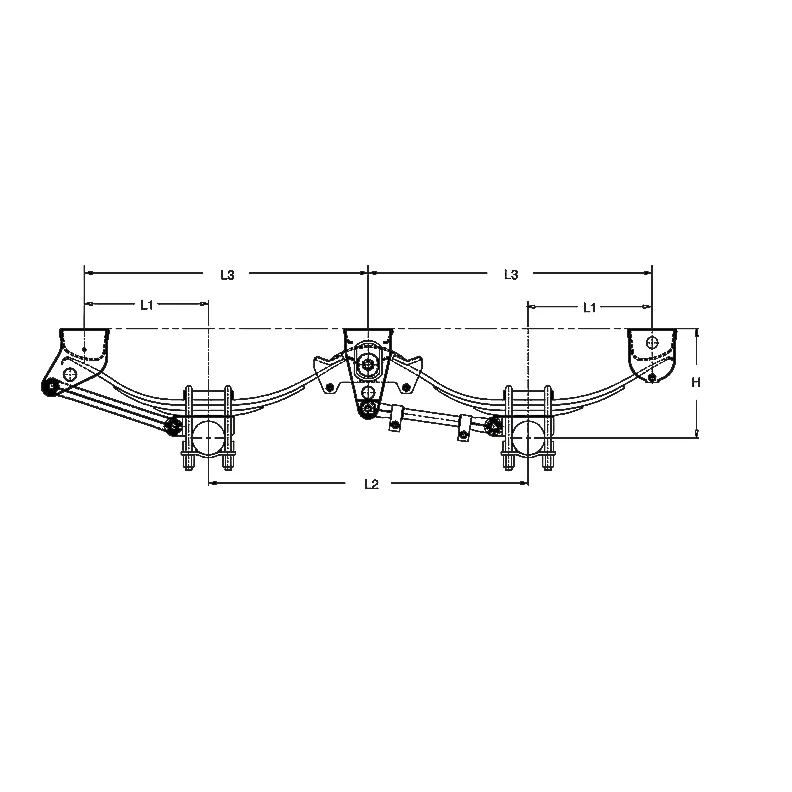

Durable Germany Type Suspension for Heavy Duty Trucks & Trailers

NewsAug.23,2025

-

American Type Welding Suspension Series: Strong, Reliable Hooks

NewsAug.22,2025

-

Hezhen 1-3mm Luminous Stone- Shijiazhuang Land Auto Component Ltd.|Durability&High Luminosity

NewsAug.18,2025

-

Hezhen 1-3mm Luminous Stone - Shijiazhuang Land Auto Component Ltd.

NewsAug.18,2025

-

Hezhen 1-3mm Luminous Stone - Shijiazhuang Land Auto Component Ltd.|Durable & Versatile

NewsAug.18,2025

-

Hezhen 1-3mm Luminous Stone - Shijiazhuang Land Auto Component Ltd.|Durable Glow-in-the-Dark Solution&Versatile Applications

NewsAug.17,2025