Июн . 12, 2025 09:45 Обратно к списку

Unveiling the Core Solutions in Commercial Vehicle and Industrial Equipment by Jost

In the realm of commercial vehicle components and industrial equipment, Jost has established itself as a global leader, offering innovative solutions that prioritize durability, safety, and efficiency. Among its diverse product portfolio, jost munster, jost material handling, jost landing leg parts, jost landing gear price, и jost king pin gauge stand out as critical elements across various industries. These products are engineered to meet rigorous standards, ensuring optimal performance in demanding environments such as logistics, transportation, and manufacturing.

Jost Munster: Precision Engineering for Specialized Applications

Within Jost’s extensive product range, jost munster represents a line of specialized components designed for specific industrial needs. These solutions often cater to niche applications, such as heavy-duty machinery or specialized transport systems. For example, in the automotive sector, jost munster parts may include high-strength couplings or precision-engineered brackets that ensure seamless integration with trailers and commercial vehicles. The materials used in jost munster products, such as austempered ductile iron and corrosion-resistant alloys, contribute to their longevity and reliability in challenging operational conditions. By combining advanced manufacturing techniques with meticulous quality control, Jost ensures that jost munster components deliver consistent performance, even under extreme loads or harsh weather conditions.

Jost Material Handling: Enhancing Efficiency in Material Movement

Jost material handling solutions are pivotal in optimizing workflow and productivity across industries. From warehouse operations to construction sites, Jost offers a comprehensive range of equipment, including electric pallet trucks, stackers, and forklifts. These tools are designed to streamline material transport, reduce manual labor, and improve overall operational efficiency. For instance, Jost’s electric pallet trucks feature ergonomic designs and advanced battery systems, allowing for smooth maneuverability and extended runtime. In industrial settings, jost material handling equipment such as reach trucks and scissor lifts enables safe and efficient access to elevated storage areas, maximizing space utilization. By integrating smart technology and robust engineering, Jost ensures that its material handling solutions adapt to diverse operational requirements, from small-scale warehouses to large industrial complexes.

Jost Landing Leg Parts: Reliable Support for Trailer Stability

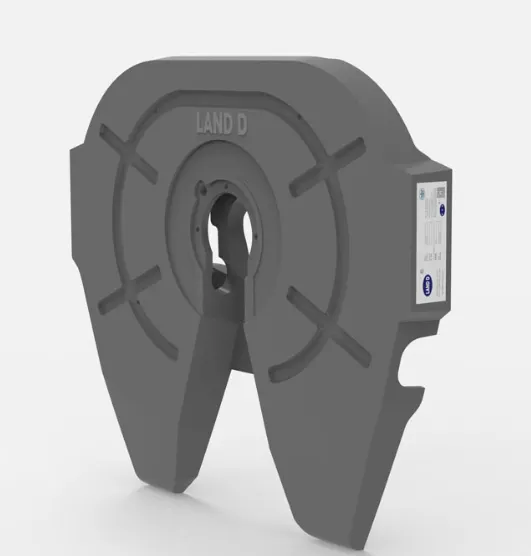

Jost landing leg parts play a vital role in maintaining the stability of trailers when detached from tractors. These components, often made from high-strength steel, are engineered to withstand heavy loads and provide secure support during loading and unloading processes. For example, Jost’s A400 series landing gear features a compact design with a high lifting capacity, making it suitable for semi-trailers and other heavy-duty applications. The landing leg parts are designed for easy installation and maintenance, with replaceable components such as gearboxes and crank handles available to minimize downtime. Regular inspection and lubrication of jost landing leg parts are essential to ensure smooth operation and prevent wear, particularly in environments with high moisture or corrosive elements.

Analyzing Factors Influencing Jost Landing Gear Price

The cost of jost landing gear varies based on several factors, including load capacity, material composition, and additional features. Entry-level models, such as the A400 series, are more budget-friendly and suitable for standard applications, while premium models like the Magnum 10-year series offer enhanced durability and higher load ratings at a higher price point. Material choices, such as aluminum for lightweight applications or steel for heavy-duty use, also impact pricing. Customization options, such as specialized coatings for corrosion resistance or integrated safety features, can further influence the final cost. Additionally, purchasing in bulk or through authorized dealers may provide cost savings, as volume discounts and promotional offers are often available. When evaluating jost landing gear price, it is crucial to balance upfront costs with long-term reliability and maintenance requirements to ensure optimal value.

Jost King Pin Gauge: Ensuring Safety and Compliance

The jost king pin gauge is a critical tool for verifying the alignment and wear of king pins in trailer coupling systems. These gauges are designed to measure key dimensions, such as diameter and wear limits, ensuring compliance with industry standards like DIN 74080 and ISO 337. For example, Jost’s KZ series king pins are compatible with specific gauges that check for deviations from factory specifications, preventing safety hazards caused by misalignment or excessive wear. Regular use of a jost king pin gauge helps identify potential issues early, reducing the risk of coupling failures and costly repairs. In commercial transportation, adherence to king pin standards is not only a safety imperative but also a regulatory requirement, making the jost king pin gauge an indispensable tool for fleet managers and maintenance teams.

FAQ: Key Insights into Jost Products

How to Maintain the Longevity of Jost Landing Leg Parts?

Regular maintenance is essential for jost landing leg parts. Inspect components for signs of corrosion, cracks, or excessive wear, and lubricate moving parts such as gears and crank handles according to the manufacturer’s guidelines. Replace worn-out parts promptly to prevent further damage. For example, if the gearbox shows signs of malfunction, replacing it with an authentic Jost replacement part ensures compatibility and performance. Additionally, avoiding overloading the landing legs and storing them in dry, protected environments can significantly extend their lifespan.

What Are the Primary Applications of Jost Material Handling Equipment?

Jost material handling equipment is versatile and finds use in various industries. Electric pallet trucks and stackers are commonly used in warehouses for loading and unloading goods, while forklifts and reach trucks are essential for transporting heavy materials in manufacturing and distribution centers. Scissor lifts and aerial work platforms are utilized in construction and maintenance for accessing elevated areas. These solutions are designed to improve efficiency, reduce physical strain, and enhance workplace safety across diverse operational settings.

How Does the Jost King Pin Gauge Ensure Compliance with Safety Standards?

The jost king pin gauge is calibrated to measure critical dimensions of king pins, such as diameter and wear limits, against industry standards like DIN 74080. By using this gauge, technicians can verify that king pins meet the required specifications, ensuring proper coupling with fifth wheels and preventing accidents caused by misalignment. Regular inspections with the gauge help identify worn or damaged king pins, allowing for timely replacement and maintaining compliance with safety regulations in commercial transportation.

What Factors Should Be Considered When Comparing Jost Landing Gear Prices?

When evaluating jost landing gear price, consider the load capacity, material quality, and additional features. Higher-capacity models, such as the H450 series with a 200,000-pound static load capacity, are more expensive but offer greater durability for heavy-duty applications. Aluminum models, like the AX100 series, are lighter and corrosion-resistant but may cost more than steel alternatives. Customization options, such as specialized coatings or integrated safety mechanisms, also affect pricing. Comparing prices from authorized dealers and considering long-term maintenance costs can help make an informed purchasing decision.

Are There Customization Options Available for Jost Munster Components?

Yes, jost munster components can often be customized to meet specific application requirements. Jost works with clients to tailor materials, dimensions, and features, ensuring compatibility with unique operational needs. For example, in specialized transport systems, jost munster couplings may be designed with specific torque ratings or mounting configurations. By collaborating with Jost’s engineering team, customers can optimize jost munster components for their exact use case, balancing performance, safety, and cost-effectiveness.

-

Why Are Specialized Components Crucial in Commercial Vehicle Maintenance and Operation?

НовостиJul.28,2025

-

Why Are Fifth Wheels Critical for Trucking and How to Select the Right One?

НовостиJul.28,2025

-

What Defines the Excellence of American Trailer Components in Key Markets?

НовостиJul.28,2025

-

What Defines the Excellence of American 5th Wheel Systems and Their Market Offerings?

НовостиJul.28,2025

-

How Do 5th Wheel Trailers Redefine Towing and Living Standards?

НовостиJul.28,2025

-

How Do 5th Wheel Systems Enhance Commercial Hauling Efficiency and Versatility?

НовостиJul.28,2025