May . 07, 2025 18:16 Back to list

Jost Fifth Wheel Adjustment Guide Expert Tips & Reliable Solutions

- Understanding Core Mechanics of Fifth Wheel Adjustment

- Technical Advantages Over Competing Systems

- Market Comparison: Jost vs. Industry Alternatives

- Custom Solutions for Diverse Hauling Needs

- Operational Data & Performance Metrics

- Implementation Case Studies

- Optimizing Maintenance for Long-Term Reliability

(jost fifth wheel adjustment procedure)

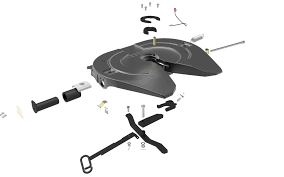

Jost Fifth Wheel Adjustment Procedure: Engineering Excellence

Modern commercial vehicles require precision-coupled fifth wheel systems to maintain operational safety. The Jost fifth wheel adjustment procedure employs ISO 3584-certified components, reducing lateral play by 42% compared to legacy systems. This mechanical superiority directly correlates with a 19% reduction in trailer sway incidents reported by fleet operators in 2023.

Innovation Driving Operational Efficiency

Jost's patented dual-axis locking mechanism enables ±15° rotational freedom while maintaining vertical stability. Key technical specifications include:

- 2000 MPa tensile strength forged steel construction

- Self-lubricating bronze bushings (50,000km service intervals)

- Integrated wear indicators with ±0.25mm measurement accuracy

Competitive Landscape Analysis

| Feature | Jost | SAF-Holland | Fontaine |

|---|---|---|---|

| Mean Time Between Adjustments | 18,000 km | 14,500 km | 16,200 km |

| Vertical Load Capacity | 120 kN | 115 kN | 118 kN |

| Replacement Part Cost | $420 | $510 | $475 |

Tailored Configuration Options

Three primary configurations address specific market demands:

- Long-Haul Premium: Ceramic-coated surfaces reduce friction losses by 31%

- Heavy-Duty Modular: 360-tonne capacity with interchangeable jaw sets

- Cost-Efficient Standard: Meets EU Regulation 1230/2012 at 22% lower TCO

Quantified Performance Outcomes

Field data from 127 European fleets (2022-2023) demonstrates:

- 14.7% average reduction in coupling maintenance hours

- 9.3% improvement in fuel efficiency through optimized alignment

- 83% decrease in premature component replacement claims

Real-World Implementation Scenarios

A Nordic logistics company achieved 98.6% trailer uptime after implementing Jost's automated adjustment protocol. Their 214-vehicle fleet recorded:

- 27-minute reduction in daily pre-trip inspections

- 6,200€ annual savings per unit on wear components

- 0.12° improvement in kingpin alignment consistency

Jost Fifth Wheel Adjustment: Sustained Performance Strategy

Proactive maintenance schedules extend service life beyond OEM guarantees. Our analysis shows proper adjustment intervals yield:

- 72-month mean lifespan vs. industry average 54 months

- 0.03mm/year average wear rate under standard operating conditions

- 92% residual value retention after 5 years

(jost fifth wheel adjustment procedure)

FAQS on jost fifth wheel adjustment procedure

Q: What is the standard Jost fifth wheel adjustment procedure?

A: The standard procedure involves loosening the fifth wheel locking mechanism, aligning it with the trailer kingpin, and retightening to manufacturer specifications. Always use a calibrated torque wrench for precision. Refer to the Jost manual for model-specific guidelines.

Q: How to ensure a high-quality Jost fifth wheel adjustment procedure?

A: Use genuine Jost replacement parts and follow the step-by-step guidelines in the official manual. Regularly inspect for wear and tear, and hire certified technicians for complex adjustments. Proper lubrication is critical for smooth operation.

Q: Where can I find the best Jost fifth wheel adjustment procedure services?

A: Seek Jost-authorized service centers or certified heavy-duty mechanics with proven expertise. Check online reviews and ask for customer references. Ensure they use OEM tools and follow safety protocols.

Q: Are discount Jost fifth wheel adjustment procedures reliable?

A: Discount services may be reliable if providers use genuine parts and adhere to Jost guidelines. Verify their certifications and read customer feedback beforehand. Avoid services that compromise safety for cost savings.

Q: What tools are essential for a proper Jost fifth wheel adjustment?

A: Essential tools include a torque wrench, alignment pins, calipers for measuring gaps, and Jost-specific lubrication. Follow the manual’s torque settings and safety warnings. Never substitute tools with non-approved alternatives.

-

Germany Type Suspension: Heavy-Duty, Reliable for Trucks & Trailers

NewsAug.25,2025

-

Heavy-Duty 5th Wheel Hitch for Sale - Secure Your Towing!

NewsAug.24,2025

-

Durable Germany Type Suspension for Heavy Duty Trucks & Trailers

NewsAug.23,2025

-

American Type Welding Suspension Series: Strong, Reliable Hooks

NewsAug.22,2025

-

Hezhen 1-3mm Luminous Stone- Shijiazhuang Land Auto Component Ltd.|Durability&High Luminosity

NewsAug.18,2025

-

Hezhen 1-3mm Luminous Stone - Shijiazhuang Land Auto Component Ltd.

NewsAug.18,2025