Okt . 11, 2024 18:42 Back to list

china fifth wheel plastic lube plate

The Importance of China Fifth Wheel Plastic Lube Plates

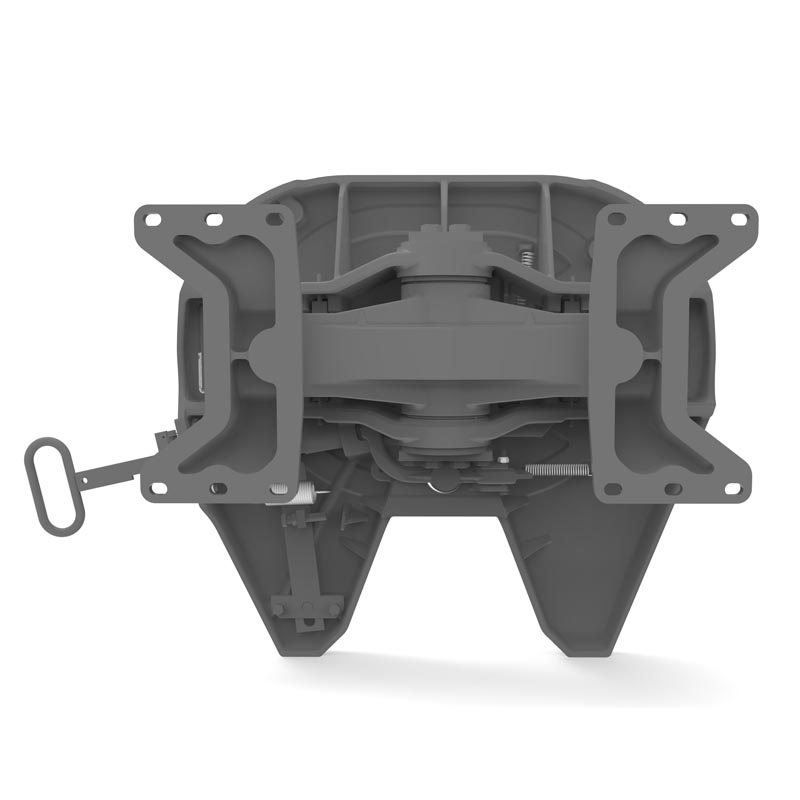

In the realm of heavy-duty transportation, the smooth operation of tractor-trailers is crucial for both safety and efficiency. One seemingly small but essential component that contributes significantly to this smooth operation is the fifth wheel plastic lube plate. Originating from the need for enhanced performance and reduced wear and tear, these plates are vital in ensuring that the connection between the tractor and trailer remains functional under various conditions. The manufacturing prowess of China in producing these vital components has garnered significant attention in the trucking industry.

What is a Fifth Wheel Plastic Lube Plate?

A fifth wheel plastic lube plate is a thin disc used between the fifth wheel coupling on a truck and the kingpin on a trailer. Its primary purpose is to facilitate the easy movement of the trailer as it pivots or articulates. The lube plate acts as a barrier between metal surfaces, greatly reducing friction and wear that could otherwise lead to damage over time. With less friction, the resistance during turning and maneuvering is minimized, providing better handling and stability for large vehicles.

The Benefits of Using Plastic Lube Plates

1. Reduced Friction The primary advantage of plastic lube plates is the significant reduction in friction compared to traditional metal-on-metal connections. This reduction not only leads to smoother operations but also prolongs the life of both the fifth wheel and the kingpin.

2. Wear Resistance Plastic lube plates are designed to withstand the harsh conditions of heavy-duty trucking. They are resistant to abrasion and wear, ensuring that they remain effective even after extended use. This quality is particularly vital when considering the varying weather conditions and loads that trucks encounter.

3. Lightweight Design The lightweight nature of plastic lube plates contributes to overall fuel efficiency. Since these plates do not add substantial weight to the vehicle, they help maintain optimal payload limits, resulting in lower fuel consumption and cost savings for trucking companies.

china fifth wheel plastic lube plate

4. Easy Installation Installing a plastic lube plate is straightforward, which minimizes downtime during maintenance. Truck operators can easily replace worn or damaged plates without requiring specialized tools or significant labor.

5. Cost-Effectiveness Chinese manufacturers have positioned themselves as leaders in the production of plastic lube plates, offering competitive pricing without compromising on quality. Businesses can benefit from these cost advantages, allowing for better budgeting and resource allocation.

The Role of China in Lube Plate Production

China has established itself as a key player in the global market for automotive components, including plastic lube plates. Advanced manufacturing techniques, along with a focus on quality assurance, allow for the mass production of durable and reliable products. Chinese manufacturers utilize high-grade plastics and innovative designs to produce lube plates that meet or exceed international standards.

Furthermore, the ability of these manufacturers to scale production according to demand makes them an attractive option for businesses looking for reliable suppliers. The ongoing improvements in logistics and supply chain management in China also facilitate quicker delivery times, ensuring that fleets remain operational without prolonged interruptions.

Conclusion

As the trucking industry continues to evolve, the importance of maintaining efficient and reliable operations cannot be overemphasized. Fifth wheel plastic lube plates are a critical component in achieving these goals. With China’s advancements in manufacturing, the availability of high-quality, cost-effective, and durable plastic lube plates positions the country as a go-to source for essential trucking parts. By investing in these components, trucking companies can enhance vehicle performance, reduce maintenance costs, and ultimately improve their bottom line.

-

Premium T5th Wheels High Quality, Best Prices & Discount Offers

NewsMay.28,2025

-

Holland Fifth Wheel Parts Breakdown Premium Quality & Discounts

NewsMay.28,2025

-

Jost Fifth Wheel Rebuild Kit – High-Quality & Durable Parts at Best Prices

NewsMay.28,2025

-

High Quality New West Freightliner Lethbridge Best Deals & Services

NewsMay.28,2025

-

Independent Diesel Services in Enid, OK Expert Repairs & Savings

NewsMay.28,2025

-

Premium Fifth Wheel Legacy Trailers Durable & Comfortable RVs

NewsMay.27,2025