Feb . 08, 2025 01:56 Back to list

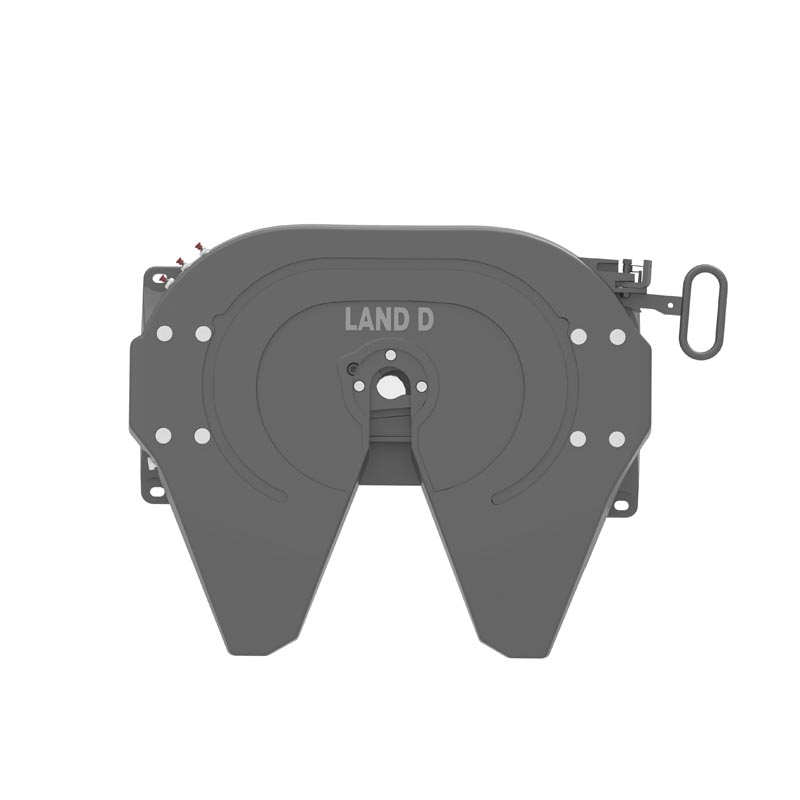

fifth wheel support

Fifth wheel supports play an essential role in the safe and efficient operation of heavy-duty vehicles. Experienced truck drivers, as well as mechanics specializing in tractor-trailer maintenance, understand just how crucial these components are. Drawing from thousands of miles on the road and extensive mechanical insights, we delve into the unique features and optimal usage of fifth wheel supports.

Trustworthiness in the context of fifth wheel supports is paramount. Trusted manufacturers adhere to strict safety standards, such as those outlined by the Society of Automotive Engineers (SAE) and the American Trucking Association (ATA). These standards ensure that every fifth wheel support meets rigorous safety and performance criteria before hitting the market. One cannot overlook the integral role of education in maintaining the fifth wheel support's effectiveness. Companies dedicated to freight safety conduct workshops and training sessions for drivers, providing hands-on experience with coupling and uncoupling techniques as well as tutorials on inspection protocols for wear and tear. Experienced drivers are often regarded as sources of authority, sharing their wisdom on the intricacies of fifth wheel maintenance, which not only enhances operational safety but also instills confidence in newer drivers. In conclusion, the fifth wheel support is more than just a piece of metal. It is a critical component engineered for excellence under pressure, withstanding tons of weight and variable conditions to keep trucking operations safe and efficient. By fostering a culture of continuous learning and adherence to authoritative standards, professionals across the transportation sector can trust in these supports to deliver the reliability they promise. Through the cumulative knowledge of seasoned mechanics and drivers, bolstered by the robust engineering of trusted manufacturers, fifth wheel supports continue to earn their place as stalwarts of heavy-duty transportation.

Trustworthiness in the context of fifth wheel supports is paramount. Trusted manufacturers adhere to strict safety standards, such as those outlined by the Society of Automotive Engineers (SAE) and the American Trucking Association (ATA). These standards ensure that every fifth wheel support meets rigorous safety and performance criteria before hitting the market. One cannot overlook the integral role of education in maintaining the fifth wheel support's effectiveness. Companies dedicated to freight safety conduct workshops and training sessions for drivers, providing hands-on experience with coupling and uncoupling techniques as well as tutorials on inspection protocols for wear and tear. Experienced drivers are often regarded as sources of authority, sharing their wisdom on the intricacies of fifth wheel maintenance, which not only enhances operational safety but also instills confidence in newer drivers. In conclusion, the fifth wheel support is more than just a piece of metal. It is a critical component engineered for excellence under pressure, withstanding tons of weight and variable conditions to keep trucking operations safe and efficient. By fostering a culture of continuous learning and adherence to authoritative standards, professionals across the transportation sector can trust in these supports to deliver the reliability they promise. Through the cumulative knowledge of seasoned mechanics and drivers, bolstered by the robust engineering of trusted manufacturers, fifth wheel supports continue to earn their place as stalwarts of heavy-duty transportation.

Previous:

Next:

Latest news

-

Heavy-Duty 5th Wheel Hitch for Sale - Secure Your Towing!

NewsAug.24,2025

-

Durable Germany Type Suspension for Heavy Duty Trucks & Trailers

NewsAug.23,2025

-

American Type Welding Suspension Series: Strong, Reliable Hooks

NewsAug.22,2025

-

Hezhen 1-3mm Luminous Stone- Shijiazhuang Land Auto Component Ltd.|Durability&High Luminosity

NewsAug.18,2025

-

Hezhen 1-3mm Luminous Stone - Shijiazhuang Land Auto Component Ltd.

NewsAug.18,2025

-

Hezhen 1-3mm Luminous Stone - Shijiazhuang Land Auto Component Ltd.|Durable & Versatile

NewsAug.18,2025