Jan . 17, 2025 05:42 Back to list

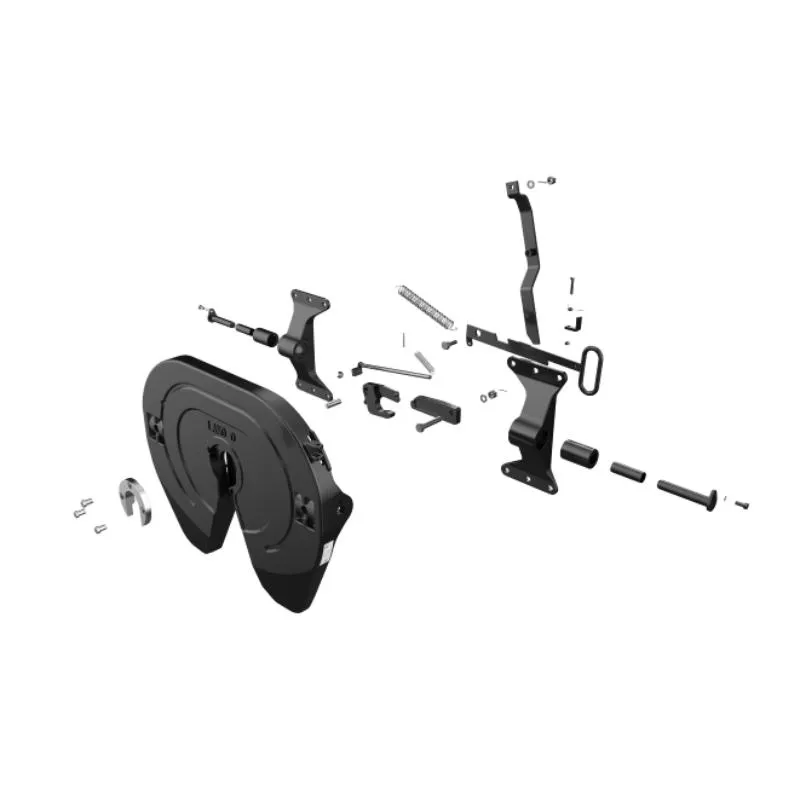

High quality JSK casting fifth wheel 37C

Adjusting a Jost fifth wheel requires a blend of technical know-how and experience to ensure optimal performance and safety. A fifth wheel is a pivotal component that connects a tractor to its trailer, allowing for smooth articulation and secure hauling. To maintain its reliability, proper adjustment is essential, ensuring it can adequately bear loads and withstand road conditions without failures.

Height adjustment is another critical factor. An improperly set height can lead to uneven load distribution and potentially catastrophic failures on the road. Measure the distance from the ground to the kingpin and compare it with the fifth wheel’s height specifications. Adjust the fifth wheel’s height by using the adjustment bolts located typically on either side of the mounting structure. This ensures the trailer sits level when connected and distributes weight evenly. Greasing the fifth wheel is a non-negotiable maintenance practice. Proper lubrication reduces resistance between moving parts, minimizes wear and tear, and prevents metal-on-metal contact. Use a high-quality fifth wheel grease and apply it thoroughly across the fifth wheel plate, ensuring even coverage. Pay attention to lubrication points as indicated by Jost, which include the pivot points and locking mechanism. Trustworthiness in equipment handling comes from consistent maintenance records. Keeping a log of every adjustment, inspection, and component replacement enhances credibility and ensures compliance with safety regulations. It also aids in tracking wear patterns and prevents future unscheduled downtimes. Finally, expert advice should always be sought if uncertain about the adjustments. Professional mechanics or maintenance technicians have the experience and precision tools necessary for optimal adjustments. Online forums and user manuals provide support and insights into common issues encountered by other operators. Properly adjusting a Jost fifth wheel ensures not only the longevity of the equipment but also the safety of operator and cargo. It fortifies the reliability of your transport operations, aligns with professional standards, and positively impacts the overall trucking experience. Quality adjustments reflect expertise, uphold authority, and establish trustworthiness with clients who depend on timeliness and reliability. Implementing these practices consistently positions your operations a step ahead in the competitive logistics landscape.

Height adjustment is another critical factor. An improperly set height can lead to uneven load distribution and potentially catastrophic failures on the road. Measure the distance from the ground to the kingpin and compare it with the fifth wheel’s height specifications. Adjust the fifth wheel’s height by using the adjustment bolts located typically on either side of the mounting structure. This ensures the trailer sits level when connected and distributes weight evenly. Greasing the fifth wheel is a non-negotiable maintenance practice. Proper lubrication reduces resistance between moving parts, minimizes wear and tear, and prevents metal-on-metal contact. Use a high-quality fifth wheel grease and apply it thoroughly across the fifth wheel plate, ensuring even coverage. Pay attention to lubrication points as indicated by Jost, which include the pivot points and locking mechanism. Trustworthiness in equipment handling comes from consistent maintenance records. Keeping a log of every adjustment, inspection, and component replacement enhances credibility and ensures compliance with safety regulations. It also aids in tracking wear patterns and prevents future unscheduled downtimes. Finally, expert advice should always be sought if uncertain about the adjustments. Professional mechanics or maintenance technicians have the experience and precision tools necessary for optimal adjustments. Online forums and user manuals provide support and insights into common issues encountered by other operators. Properly adjusting a Jost fifth wheel ensures not only the longevity of the equipment but also the safety of operator and cargo. It fortifies the reliability of your transport operations, aligns with professional standards, and positively impacts the overall trucking experience. Quality adjustments reflect expertise, uphold authority, and establish trustworthiness with clients who depend on timeliness and reliability. Implementing these practices consistently positions your operations a step ahead in the competitive logistics landscape.

Previous:

Latest news

-

Heavy-Duty 5th Wheel Hitch for Sale - Secure Your Towing!

NewsAug.24,2025

-

Durable Germany Type Suspension for Heavy Duty Trucks & Trailers

NewsAug.23,2025

-

American Type Welding Suspension Series: Strong, Reliable Hooks

NewsAug.22,2025

-

Hezhen 1-3mm Luminous Stone- Shijiazhuang Land Auto Component Ltd.|Durability&High Luminosity

NewsAug.18,2025

-

Hezhen 1-3mm Luminous Stone - Shijiazhuang Land Auto Component Ltd.

NewsAug.18,2025

-

Hezhen 1-3mm Luminous Stone - Shijiazhuang Land Auto Component Ltd.|Durable & Versatile

NewsAug.18,2025