Aug . 30, 2024 07:24 Back to list

Liner Thickness Product - Precision Solutions for Your Needs

Understanding Liner Thickness in Manufacturing Products

Liner thickness is a critical factor in various manufacturing processes, particularly in industries that involve the production of composite materials, packaging, and construction components. The term liner typically refers to a layer or coating that is applied to a substrate for protection, functional enhancement, or aesthetic purposes. The thickness of this liner can significantly impact the product's overall performance, durability, and cost-effectiveness.

Importance of Liner Thickness

There are several reasons why liner thickness is crucial in product development. First and foremost, it has a direct influence on the mechanical properties of the end product. A thicker liner may provide increased strength and resistance to wear and tear, making it suitable for heavy-duty applications such as industrial piping or high-traffic flooring. Conversely, a thinner liner might be more appropriate for lightweight applications where flexibility and ease of handling are required.

Moreover, liner thickness can affect thermal and acoustic insulation properties. In environments where temperature fluctuations are a concern, a thicker liner may offer better insulation, resulting in energy savings and improved comfort levels. Similarly, for products that need to minimize sound transmission, like walls or partitions, a thicker liner can play a vital role in soundproofing.

Balancing Performance and Cost

While it is clear that liner thickness can enhance product characteristics, manufacturers must also consider cost implications. Thicker liners often require more material, which increases production costs. For companies operating on tight margins, finding the right balance between adequate liner thickness and overall cost is essential.

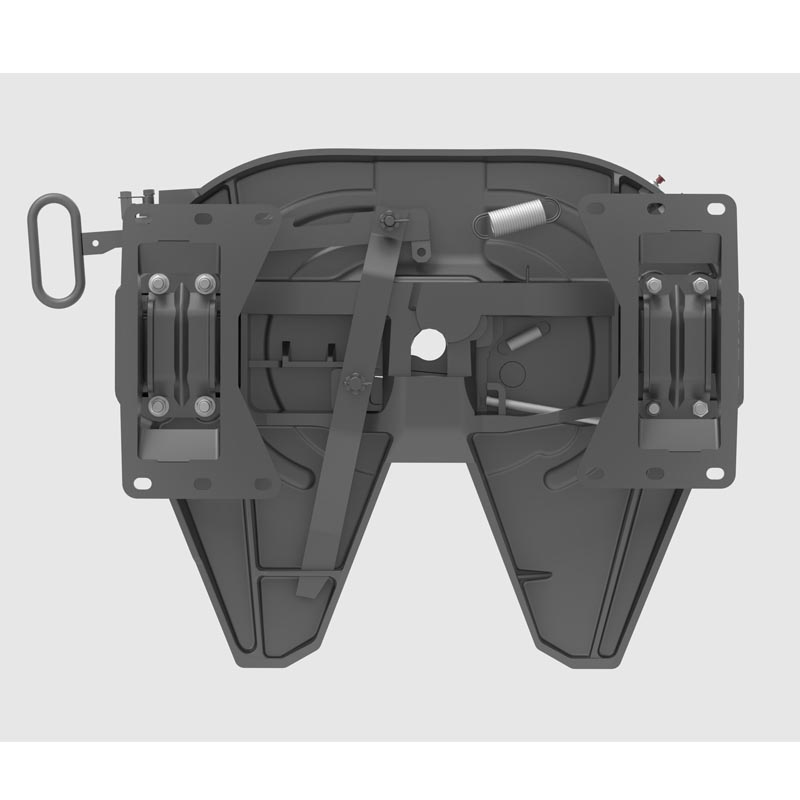

liner thickness product

Additionally, thicker liners can complicate manufacturing processes, leading to longer production times and potential challenges in quality control. As a result, manufacturers should conduct thorough testing and analysis to determine the optimal liner thickness for their specific application. This includes considering factors such as the intended use of the product, expected wear conditions, and industry standards.

Applications of Liner Thickness

The concept of liner thickness is applicable in numerous sectors. In the packaging industry, for example, the thickness of the liner in flexible packaging films can influence barrier properties, affecting how well products are protected from moisture, oxygen, and contaminants. In building materials, exterior wall liners designed to provide insulation and weather resistance must be carefully engineered to achieve the right thickness for maximum longevity and performance.

In the automotive sector, the development of liners for engine components or interior elements can improve the vehicle’s overall efficiency and comfort. Foreseeing how changes in liner thickness can alter the performance and safety of such components is key for engineers and product designers.

Conclusion

In conclusion, liner thickness is a multifaceted aspect of product manufacturing that requires careful consideration. By understanding its importance, manufacturers can optimize their designs to achieve desired performance without unnecessarily increasing costs. As industries continue to evolve and demand higher quality products, the significance of liner thickness will only become more pronounced, making it a vital area for research and innovation in manufacturing.

-

Imperial Truck Repair Hayward CA - High Quality, Affordable & Reliable Services

NewsJun.10,2025

-

High Quality Fontaine International do Brasil – Best Discount Offers Online

NewsJun.10,2025

-

Premium Fontaine Valves - High Quality & Discount Offers Durable

NewsJun.10,2025

-

Premium Fifth Wheel King Pins Top Durability & Savings

NewsJun.10,2025

-

Best Semi Trailer Kingpins for Sale Premium & Discounted

NewsJun.10,2025

-

Premium Holland Fifth Wheel Slider Parts Durable & Discount Deals

NewsJun.09,2025