Sht . 28, 2024 12:05 Back to list

oem fontaine fifth wheel rebuild instructions

OEM Fontaine Fifth Wheel Rebuild Instructions

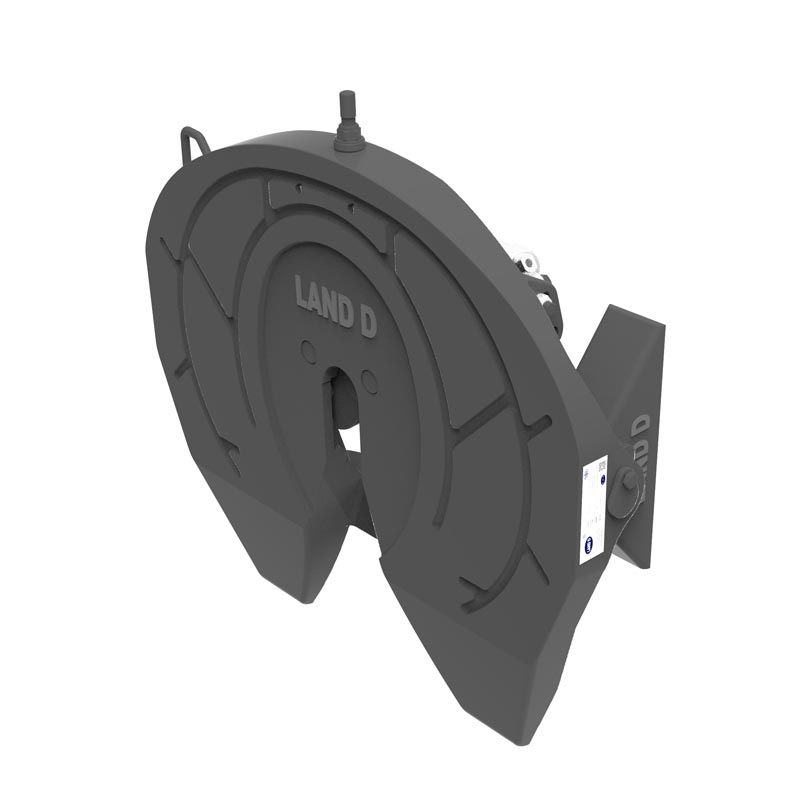

The Fontaine fifth wheel is a critical component in the trucking industry, connecting the truck to the trailer and enabling smooth transportation of goods. Over time, wear and tear can affect its functionality, necessitating a rebuild. Here’s a comprehensive guide on how to effectively rebuild an OEM Fontaine fifth wheel.

Step 1 Gather Necessary Tools and Materials

Before beginning the rebuild, ensure you have the right tools and materials on hand. You'll need basic tools such as wrenches, socket sets, screwdrivers, and a hammer. Additionally, procure a rebuild kit from an OEM supplier, which typically includes replacement parts such as bearings, seals, grease, and any necessary bolts or fasteners.

Step 2 Safety Precautions

Safety should always be a priority in any maintenance task. Ensure that the truck is on a flat surface and the fifth wheel is not under any load. Use wheel chocks to prevent any movement of the truck. Wearing appropriate personal protective equipment (PPE), such as gloves and safety glasses, is crucial to avoid injuries.

Step 3 Disassemble the Fifth Wheel

Start by removing the fifth wheel from the truck chassis. This usually involves unbolting it from the frame and disconnecting air and electrical connections if applicable. Once removed, place the fifth wheel on a clean workbench to facilitate the rebuilding process. Carefully disassemble the fifth wheel by removing the retaining clips and bolts, taking note of the order of parts for easier reassembly.

Step 4 Inspect Components

oem fontaine fifth wheel rebuild instructions

Examine all components for signs of wear or damage. Pay particular attention to the locking mechanism, jaws, and pivot pins. Any worn parts should be replaced with new ones from your rebuild kit. Cleaning all parts with a suitable solvent will also enhance performance and longevity.

Step 5 Reassemble with New Parts

Begin reassembling the fifth wheel, starting from the base. Use the replacement parts from the rebuild kit, ensuring that all components are correctly positioned and aligned. Pay attention to the torque specifications provided in the OEM manual to ensure all bolts are tightened adequately.

Step 6 Apply Lubrication

Proper lubrication is vital for the smooth operation of the fifth wheel. Use high-quality grease in designated areas, particularly on the pivot points and jaws. This will help in reducing friction and wear during operation.

Step 7 Final Inspection and Reinstallation

Once the fifth wheel is fully assembled and lubricated, conduct a final inspection to verify that all parts are correctly installed and functioning. Reinstall the fifth wheel onto the truck chassis, reconnecting all necessary components and ensuring everything is secure.

Conclusion

Rebuilding an OEM Fontaine fifth wheel is a straightforward process with the right tools and diligence. Regular maintenance can prolong the life of the fifth wheel and ensure safe trucking operations. Always refer to the specific OEM guidelines for your model to ensure compliance and safety during the rebuild.

-

Imperial Truck Repair Hayward CA - High Quality, Affordable & Reliable Services

NewsJun.10,2025

-

High Quality Fontaine International do Brasil – Best Discount Offers Online

NewsJun.10,2025

-

Premium Fontaine Valves - High Quality & Discount Offers Durable

NewsJun.10,2025

-

Premium Fifth Wheel King Pins Top Durability & Savings

NewsJun.10,2025

-

Best Semi Trailer Kingpins for Sale Premium & Discounted

NewsJun.10,2025

-

Premium Holland Fifth Wheel Slider Parts Durable & Discount Deals

NewsJun.09,2025