Jan . 14, 2025 10:05 Back to list

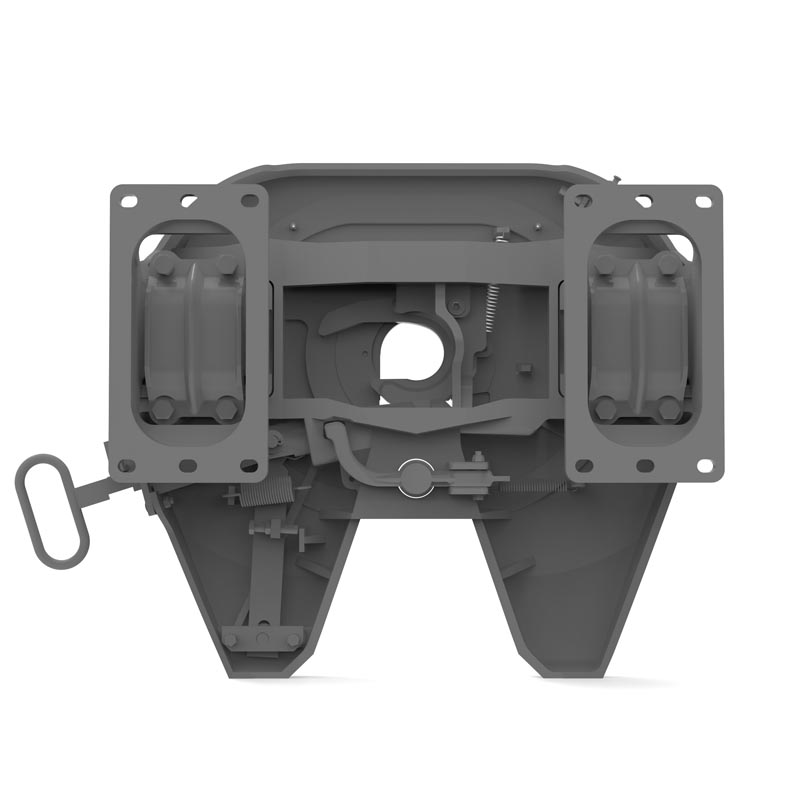

semi trailer jack legs

Navigating the intricacies of semi-trailer jack legs reveals much about their importance in the transportation industry. Semi-trailer jack legs, often referred to as landing gear, play a pivotal role in stabilizing the trailer when it is unhitched from the tractor or other towing vehicle. Understanding their function, maintenance, and selection is essential for optimizing fleet efficiency and safety.

Maintaining jack legs involves routine inspection and proper lubrication of moving parts. Operators should be trained to recognize signs of wear, such as rust or deformation, that might compromise structural integrity. Regular maintenance checks extend the lifespan of the equipment and ensure compliance with safety standards, further enhancing trust in operation. From an authority perspective, industry standards and regulatory compliance cannot be overlooked. Adherence to established guidelines from bodies such as the Department of Transportation (DOT) in the USA ensures that jack legs meet critical safety and performance standards. This compliance underpins both trust and reliability, validating the equipment in the eyes of stakeholders including clients, insurance companies, and safety inspectors. Investing in quality semi-trailer jack legs is an investment in operational efficiency, safety, and longevity of transport vehicles. The expertise required to select the right jack legs aids in creating a fleet that meets the demanding needs of modern logistics, further positioning companies as leaders in a competitive supply chain environment. In conclusion, the expertise, authoritativeness, and trustworthiness within the domain of semi-trailer jack legs hinge on informed choices and rigorous maintenance schedules. For those in the logistics industry, prioritizing these aspects can lead to more efficient and reliable operations, ensuring the safety of both personnel and cargo during transit. These insights into the nuances of semi-trailer jack legs offer a unique perspective that enhances understanding and informs better decision-making.

Maintaining jack legs involves routine inspection and proper lubrication of moving parts. Operators should be trained to recognize signs of wear, such as rust or deformation, that might compromise structural integrity. Regular maintenance checks extend the lifespan of the equipment and ensure compliance with safety standards, further enhancing trust in operation. From an authority perspective, industry standards and regulatory compliance cannot be overlooked. Adherence to established guidelines from bodies such as the Department of Transportation (DOT) in the USA ensures that jack legs meet critical safety and performance standards. This compliance underpins both trust and reliability, validating the equipment in the eyes of stakeholders including clients, insurance companies, and safety inspectors. Investing in quality semi-trailer jack legs is an investment in operational efficiency, safety, and longevity of transport vehicles. The expertise required to select the right jack legs aids in creating a fleet that meets the demanding needs of modern logistics, further positioning companies as leaders in a competitive supply chain environment. In conclusion, the expertise, authoritativeness, and trustworthiness within the domain of semi-trailer jack legs hinge on informed choices and rigorous maintenance schedules. For those in the logistics industry, prioritizing these aspects can lead to more efficient and reliable operations, ensuring the safety of both personnel and cargo during transit. These insights into the nuances of semi-trailer jack legs offer a unique perspective that enhances understanding and informs better decision-making.

Previous:

Next:

Latest news

-

Imperial Truck Repair Hayward CA - High Quality, Affordable & Reliable Services

NewsJun.10,2025

-

High Quality Fontaine International do Brasil – Best Discount Offers Online

NewsJun.10,2025

-

Premium Fontaine Valves - High Quality & Discount Offers Durable

NewsJun.10,2025

-

Premium Fifth Wheel King Pins Top Durability & Savings

NewsJun.10,2025

-

Best Semi Trailer Kingpins for Sale Premium & Discounted

NewsJun.10,2025

-

Premium Holland Fifth Wheel Slider Parts Durable & Discount Deals

NewsJun.09,2025