Oct . 21, 2024 12:35 Back to list

Wheel Coupling Price List and Comparison Guide for Optimal Selection

Understanding Wheel Coupling Price Lists A Comprehensive Guide

When it comes to machinery and equipment, wheel coupling plays a crucial role in ensuring smooth operations. It provides the necessary link between the driving and driven components, allowing for the transfer of torque while accommodating misalignment. As industries continue to evolve, the demand for high-quality wheel couplings has surged, leading to a diverse market with a range of options and corresponding price lists. This article will explore the factors influencing wheel coupling prices, the various types available, and how to effectively navigate price lists to make informed purchasing decisions.

Factors Influencing Wheel Coupling Prices

Several key factors contribute to the pricing of wheel couplings. One of the primary considerations is the material used in manufacturing the couplings. Common materials include steel, aluminum, and various polymers, each offering different levels of strength, durability, and resistance to wear. Couplings made from high-grade materials generally command higher prices due to their enhanced performance and longevity.

Another significant factor is the design and type of coupling. There are several different types of wheel couplings, including rigid couplings, flexible couplings, and universal joints, each serving specific purposes and applications. For instance, flexible couplings are designed to accommodate misalignment and are often more expensive due to their complex design and functionality.

The manufacturing process also plays a role in determining prices. Custom-made couplings, which are tailored to meet specific requirements, will typically be more expensive than standard alternatives. The level of precision in machining and the technology used in production also impact costs.

Navigating Wheel Coupling Price Lists

When examining a wheel coupling price list, it's crucial to consider not only the price but also the specifications and performance characteristics of each coupling. A comprehensive price list should include detailed information such as the coupling type, material, size, load capacity, and any additional features (e.g., corrosion resistance, temperature ratings) that may affect its performance in specific applications.

To effectively navigate price lists, potential buyers should start by identifying their requirements. Understanding the operational environment and the specific needs of the machinery will help narrow down the options. For example, a high-torque application may necessitate a more robust coupling, while lighter applications may have more flexibility in choosing materials.

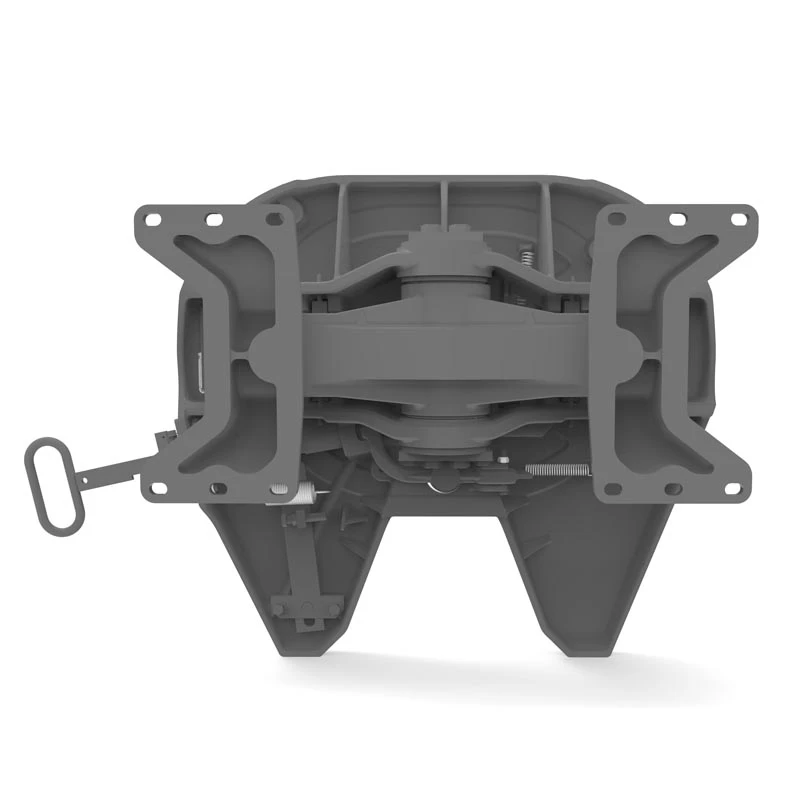

wheel coupling pricelist

It's also advisable to compare prices from multiple suppliers. While a lower price can be tempting, it's essential to ensure that the coupling meets the necessary quality standards. Additionally, considering the reputation of the manufacturer and reading customer reviews can provide insight into the reliability and performance of the couplings being considered.

Types of Wheel Couplings

Wheel couplings come in various designs, each suited for specific applications. Here are a few common types

1. Rigid Couplings These are used to connect shafts that are perfectly aligned. They offer high torque transmission with no misalignment compensation, making them ideal for applications with precise alignment.

2. Flexible Couplings Designed to accommodate misalignment, these couplings are essential in applications where shafts may not align perfectly due to thermal expansion or installation errors. They are commonly used in various industries, from automotive to manufacturing.

3. Universal Joints These couplings are capable of accommodating angular misalignment and are often used in applications where shafts operate at varied angles to each other, such as in motor vehicles.

4. Oldham Couplings These consist of three discs and are ideal for applications requiring high torque capacity and moderate misalignment accommodation.

Conclusion

Understanding wheel coupling price lists is essential for anyone involved in industrial machinery or applications requiring the transfer of torque. By considering material quality, design specifications, and application needs, buyers can make informed decisions that align with their operational requirements. Whether investing in standard or custom couplings, careful analysis of price lists and supplier options can lead to successful procurement, ultimately enhancing the efficiency and longevity of machinery and equipment.

-

Imperial Truck Repair Hayward CA - High Quality, Affordable & Reliable Services

NewsJun.10,2025

-

High Quality Fontaine International do Brasil – Best Discount Offers Online

NewsJun.10,2025

-

Premium Fontaine Valves - High Quality & Discount Offers Durable

NewsJun.10,2025

-

Premium Fifth Wheel King Pins Top Durability & Savings

NewsJun.10,2025

-

Best Semi Trailer Kingpins for Sale Premium & Discounted

NewsJun.10,2025

-

Premium Holland Fifth Wheel Slider Parts Durable & Discount Deals

NewsJun.09,2025