பிப் . 10, 2025 09:26 Back to list

semi kingpin size

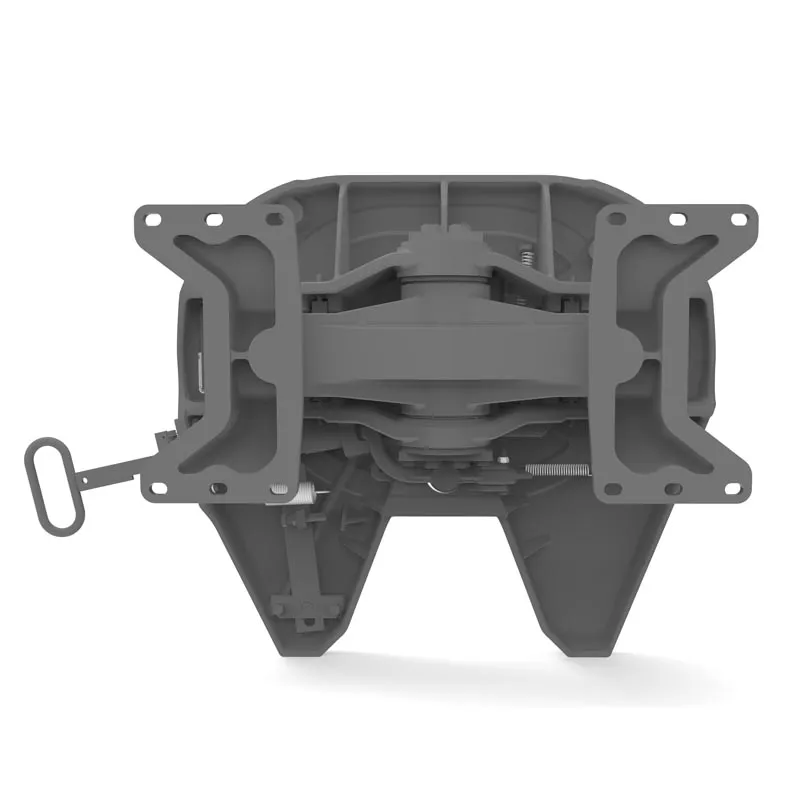

In the realm of truck and trailer manufacturing and customization, the concept of semi kingpin size is often overshadowed by more commonly discussed components. However, as a crucial element in the articulation between the tractor and the trailer, understanding the intricacies of semi kingpin size can have a profound impact on vehicle performance, safety, and efficiency.

A noteworthy trend seen among logistics companies is the shift toward modular design, allowing diverse trailer configurations without compromising on the robustness of the fifth-wheel assembly. Here, the adaptability in kingpin size facilitates a smoother transition between varying trailer types, ultimately improving logistical efficiency and reducing downtime often associated with equipment incompatibility. For fleet managers looking to optimize their assets, investing in telemetry systems that monitor the stress levels imposed on the kingpin during transit offers a new level of authoritativeness in vehicle maintenance. By analyzing data on kingpin wear and stress, preventive measures can be instituted, safeguarding against potential on-road failures. Trustworthiness in the selection and maintenance of semi kingpin size boils down to adhering to well-established industry standards such as the SAE J700, which outlines specifications for kingpin construction and installation. Leveraging these guidelines not only ensures compliance with safety regulations but also fosters confidence among stakeholders. Moreover, engaging with reputable manufacturers and suppliers who offer certified components aids in instilling trust. These entities typically provide detailed documentation and guidelines for installation and usage, ensuring that purchasers are well-informed and equipped to make educated decisions regarding their setups. In conclusion, while the semi kingpin size might initially appear as a minor detail within the broader scope of heavy vehicle operations, its impact on performance and safety is undeniably significant. By applying a blend of technical understanding, practical experience, and rigorous testing, stakeholders can capitalize on improved reliability and efficiency, ultimately driving both successful outcomes and industry advancement.

A noteworthy trend seen among logistics companies is the shift toward modular design, allowing diverse trailer configurations without compromising on the robustness of the fifth-wheel assembly. Here, the adaptability in kingpin size facilitates a smoother transition between varying trailer types, ultimately improving logistical efficiency and reducing downtime often associated with equipment incompatibility. For fleet managers looking to optimize their assets, investing in telemetry systems that monitor the stress levels imposed on the kingpin during transit offers a new level of authoritativeness in vehicle maintenance. By analyzing data on kingpin wear and stress, preventive measures can be instituted, safeguarding against potential on-road failures. Trustworthiness in the selection and maintenance of semi kingpin size boils down to adhering to well-established industry standards such as the SAE J700, which outlines specifications for kingpin construction and installation. Leveraging these guidelines not only ensures compliance with safety regulations but also fosters confidence among stakeholders. Moreover, engaging with reputable manufacturers and suppliers who offer certified components aids in instilling trust. These entities typically provide detailed documentation and guidelines for installation and usage, ensuring that purchasers are well-informed and equipped to make educated decisions regarding their setups. In conclusion, while the semi kingpin size might initially appear as a minor detail within the broader scope of heavy vehicle operations, its impact on performance and safety is undeniably significant. By applying a blend of technical understanding, practical experience, and rigorous testing, stakeholders can capitalize on improved reliability and efficiency, ultimately driving both successful outcomes and industry advancement.

Previous:

Next:

Latest news

-

Heavy-Duty 5th Wheel Hitch for Sale - Secure Your Towing!

NewsAug.24,2025

-

Durable Germany Type Suspension for Heavy Duty Trucks & Trailers

NewsAug.23,2025

-

American Type Welding Suspension Series: Strong, Reliable Hooks

NewsAug.22,2025

-

Hezhen 1-3mm Luminous Stone- Shijiazhuang Land Auto Component Ltd.|Durability&High Luminosity

NewsAug.18,2025

-

Hezhen 1-3mm Luminous Stone - Shijiazhuang Land Auto Component Ltd.

NewsAug.18,2025

-

Hezhen 1-3mm Luminous Stone - Shijiazhuang Land Auto Component Ltd.|Durable & Versatile

NewsAug.18,2025