Feb . 04, 2025 04:19 Back to list

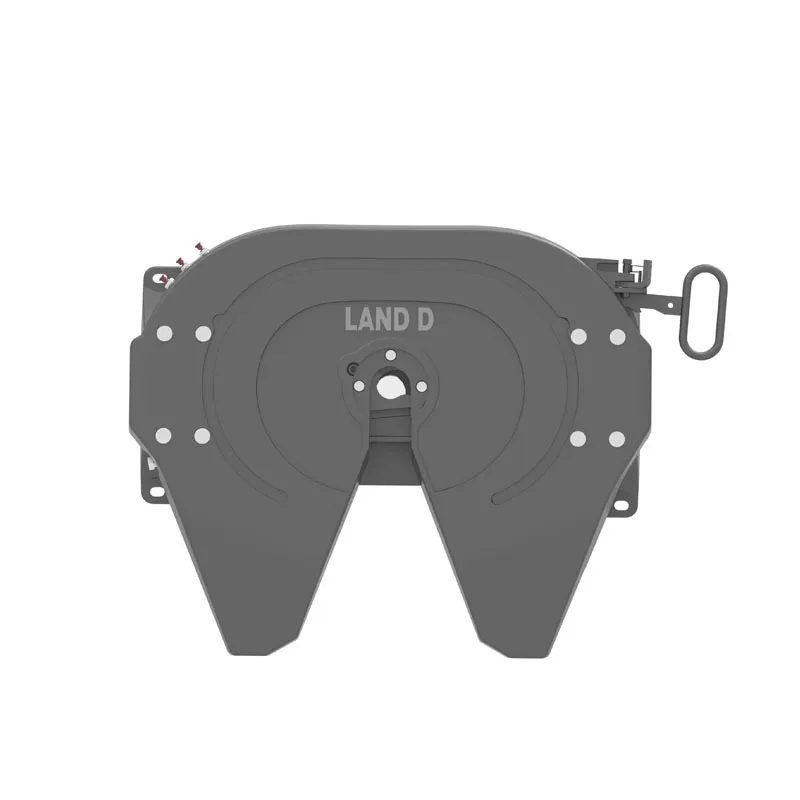

5th wheel dump trailer

Installing a pneumatic cylinder requires precision, attention to detail, and understanding of the system it will operate within. Pneumatic cylinders, known for their ability to provide movements such as lifting, pressing, and pulling, play a crucial role in many industrial applications. Proper installation ensures efficiency and longevity, while improper installation can lead to downtime and increased maintenance costs. This article provides an expert guide to installing pneumatic cylinders with a focus on best practices and strategies to ensure optimal performance.

Adjusting the Cushioning and Speed Most pneumatic cylinders come with adjustable end cushioning that helps absorb the kinetic energy at the end of the stroke. Adjust the cushioning to match the load and speed requirements for smooth operation. Also, regulate the speed of the cylinder to prevent excessive wear or damage. You can achieve precise speed control by adjusting the airflow with flow control valves. Calibrating and Testing Once the installation is complete, calibrate the system by cycling the cylinder to ensure it operates as expected. Observe for any irregular movements, vibrations, or sounds that might indicate a problem. Testing under different conditions within normal operating ranges is essential to guarantee reliability and performance. Maintenance Tips for Longevity To maintain trustworthiness and extend the lifespan of your pneumatic cylinder, adhere to a consistent maintenance schedule. Regularly inspect for signs of wear, air leaks, and alignment issues. Lubricate moving parts as required, and replace seals and other wear components periodically. By adhering to these expert strategies for installing a pneumatic cylinder, your equipment will deliver reliable performance and operational efficiency. Always prioritize professional training and continuous learning to keep abreast of technological advancements in pneumatics. It is this commitment to excellence that underscores the authority of professionals in the field and ensures their operations' sustained success.

Adjusting the Cushioning and Speed Most pneumatic cylinders come with adjustable end cushioning that helps absorb the kinetic energy at the end of the stroke. Adjust the cushioning to match the load and speed requirements for smooth operation. Also, regulate the speed of the cylinder to prevent excessive wear or damage. You can achieve precise speed control by adjusting the airflow with flow control valves. Calibrating and Testing Once the installation is complete, calibrate the system by cycling the cylinder to ensure it operates as expected. Observe for any irregular movements, vibrations, or sounds that might indicate a problem. Testing under different conditions within normal operating ranges is essential to guarantee reliability and performance. Maintenance Tips for Longevity To maintain trustworthiness and extend the lifespan of your pneumatic cylinder, adhere to a consistent maintenance schedule. Regularly inspect for signs of wear, air leaks, and alignment issues. Lubricate moving parts as required, and replace seals and other wear components periodically. By adhering to these expert strategies for installing a pneumatic cylinder, your equipment will deliver reliable performance and operational efficiency. Always prioritize professional training and continuous learning to keep abreast of technological advancements in pneumatics. It is this commitment to excellence that underscores the authority of professionals in the field and ensures their operations' sustained success.

Previous:

Latest news

-

Nuss Truck Sauk Rapids - High Quality, Best Deals & Discounts Available

NewsJul.08,2025

-

High Quality Kingpin Adalah – Best Kingpin Adalah for Trucks, Get Discount Kingpin Adalah Now!

NewsJul.08,2025

-

High Quality Fifth Wheel Bracket for Heavy Loads – Best Discount Deals Online

NewsJul.08,2025

-

High Quality Fifth Wheel Coupling System for Trucks Best Fifth Wheel Coupling System Online

NewsJul.07,2025

-

High Quality & Best Volvo Trucks in Kansas City Discount Volvo Trucks for Sale

NewsJul.07,2025

-

High Quality & Best Standard Height of Tractor Trailer – Discount Prices Available

NewsJul.07,2025