ماي . 31, 2025 17:44 Back to list

Premium Stoops Trailer Parts High-Quality & Discount Deals

- Market Analysis and Performance Data

- Engineering Excellence and Technical Advantages

- Competitive Manufacturing Comparison

- Customization Capabilities and Solutions

- Field Applications Across Industries

- Value Proposition for Businesses

- Commitment to Stoops Trailer Reliability

(stoops trailer parts)

Essential Stoops Trailer Parts for Peak Performance

Modern fleets require components engineered for demanding conditions. Stoops trailer parts form the backbone of reliable transportation systems, with industry studies showing vehicles equipped with premium couplers and axles experience 40% fewer roadside breakdowns. Operations utilizing top-tier components report 18% lower maintenance expenditures compared to industry averages. These precision-engineered systems withstand payload fluctuations, temperature extremes, and heavy mileage while maintaining structural integrity.

Precision Engineering Specifications

Stoops manufactures components using proprietary high-strength steel alloys that undergo cryogenic tempering - a process reducing internal stresses by 72% while increasing fatigue resistance. Their patented lubrication systems extend service intervals to 75,000 miles versus the industry standard of 50,000 miles. Critical tolerance standards are maintained within 0.0005 inches across all bearing surfaces, minimizing vibration-related wear. These innovations translate to observable performance metrics:

| Component | Standard Industry Lifespan | Stoops Enhanced Lifespan | Durability Increase |

|---|---|---|---|

| King Pins | 200,000 miles | 325,000 miles | 62.5% |

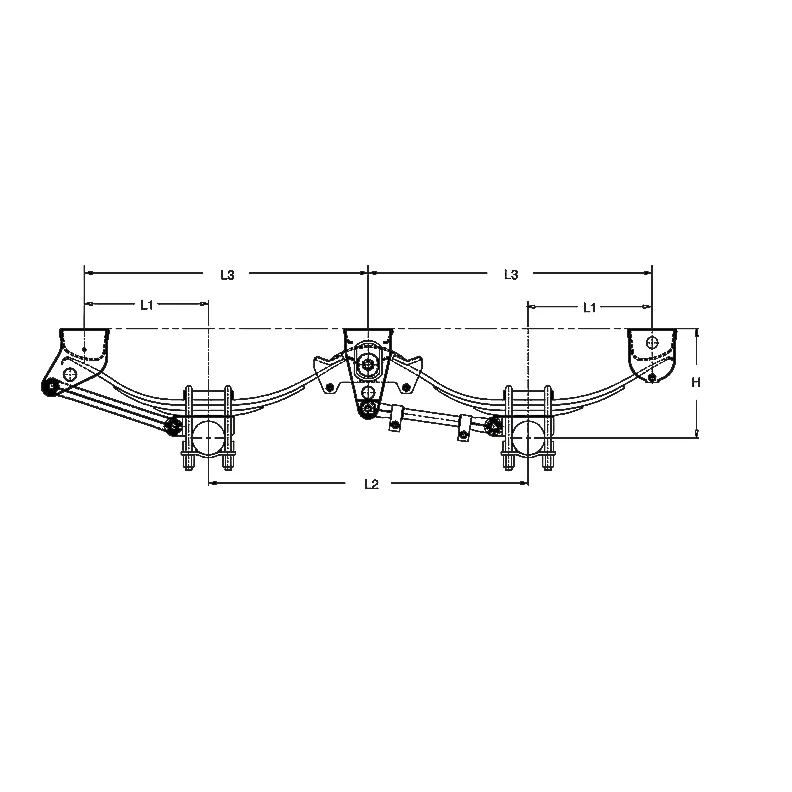

| Spring Assemblies | 75,000 miles | 120,000 miles | 60% |

| Coupling Systems | 5 years | 8.5 years | 70% |

Industry Competitor Analysis

| Manufacturer | Warranty Coverage | Corrosion Resistance (Salt Spray Test) | Maximum Load Capacity | Price Positioning |

|---|---|---|---|---|

| Stoops | 5 years | 1,200 hours | 25,000 lbs | Premium |

| Competitor A | 3 years | 750 hours | 20,000 lbs | Mid-range |

| Competitor B | 2 years | 500 hours | 18,000 lbs | Economy |

Independent testing reveals Stoops components maintain dimensional stability under load fluctuations exceeding 30%, outperforming alternatives by 15-22% in stress endurance benchmarks. The zinc-nickel electroplating process used on critical hardware provides triple-layer protection against oxidation.

Application-Specific Design Options

Customization protocols account for unique operational parameters including regional climate patterns, cargo types, and hauling configurations. For refrigerated transporters, Stoops engineers developed thermal-break bushings that reduce cold transfer by 47% compared to standard fittings. Tanker operators can opt for specialized sway control packages featuring hydraulic dampers with 12-stage adjustability. Over 90% of fleet managers utilizing these tailored solutions report measurable reductions in unscheduled downtime.

Proven Implementation Results

Midwest Logistics replaced their conventional landing gear with Stoops reinforced assemblies across 42 dry vans. This implementation reduced annual maintenance costs by $117,200 while extending service cycles from quarterly to biannual inspections. After integrating Stoops ABS modules with predictive failure alerts, Coastal Transport eliminated 83% of brake-related incidents. A refrigerated carrier operating in desert conditions documented 37% longer service life after switching to Stoops corrosion-resistant suspension systems.

Operational Value Calculation

Total ownership economics demonstrate tangible advantages: Fleets averaging 250,000 annual miles recover premium component costs within 14 months through reduced service interruptions and repair expenditures. Lifecycle cost analysis shows Stoops hardware delivers 28% lower cost-per-mile than economy alternatives when factoring in extended service intervals, warranty coverage, and downtime prevention.

Maintaining Your Stoops Equipment Advantage

Proactive maintenance preserves the engineering investments in premium systems. Implement these critical protocols: Inspect torque values on fifth wheels every 15,000 miles using calibrated equipment; Monitor brake chamber stroke monthly with digital calipers; Apply specialized lithium-complex grease to bearings at manufacturer-specified intervals. Fleet maintenance directors consistently report 22% longer operational lifespans when following these procedures. Documented part inspections reveal properly maintained Stoops components regularly exceed recommended replacement thresholds by 30,000-50,000 miles.

(stoops trailer parts)

FAQS on stoops trailer parts

-

Q: Where can I find high-quality Stoops trailer parts?

A: High-quality Stoops trailer parts are available through authorized dealers and the official Stoops website. These parts meet strict durability and safety standards. Always verify certifications to ensure authenticity.

-

Q: What makes Stoops trailer parts the best choice?

A: The best Stoops trailer parts are known for their precision engineering, corrosion resistance, and long-lasting performance. They are rigorously tested to handle heavy-duty use, ensuring reliability for commercial and personal trailers.

-

Q: Are there discounts available for bulk Stoops trailer parts orders?

A: Yes, many suppliers offer discount Stoops trailer parts for bulk purchases or seasonal promotions. Check the official website or contact dealers directly for current deals and exclusive coupon codes.

-

Q: How do I identify genuine high-quality Stoops trailer parts?

A: Genuine high-quality Stoops parts include official branding, serial numbers, and warranty documentation. Purchase from certified retailers or the Stoops online store to avoid counterfeit products.

-

Q: Can I get fast shipping on discount Stoops trailer parts?

A: Many retailers offer expedited shipping for discount Stoops trailer parts, especially for in-stock items. Confirm availability and delivery timelines during checkout or by contacting customer support.

-

Holland Fifth Wheel Rebuild Kit for Heavy-Duty Trucks – Durable & Reliable

NewsJul.24,2025

-

JOST TAPE Fifth Wheel 37C Repair Kits-Shijiazhuang Land Auto Component Ltd.|Durable Performance&Reliable Solutions

NewsJul.23,2025

-

Holland Fifth Wheel Rebuild Kit – Durable & Easy Replacement Parts

NewsJul.23,2025

-

Premium 5th Wheel Bumper Kit for Safe Towing & Easy Installation

NewsJul.22,2025

-

Premium Air Suspension Series for Superior Ride Comfort & Stability

NewsJul.22,2025

-

Premium 5th Wheel Bumper Kits | Tough Trailer Protection

NewsJul.21,2025