Nov . 11, 2024 05:31 Back to list

Optimal Semi Truck Kingpin Dimensions for Enhanced Performance and Safety

Understanding Semi Kingpin Sizes Choosing the Best for Your Needs

When discussing the intricacies of trucking, particularly in the realm of semi-trailers, one component frequently overlooked by the untrained eye is the kingpin. The semi kingpin, a critical element in the coupling of a truck and trailer, plays an essential role in maintaining the stability and safety of the vehicle on the road. Understanding the various sizes and specifications of semi kingpins can significantly impact both performance and safety for trucking professionals.

What is a Semi Kingpin?

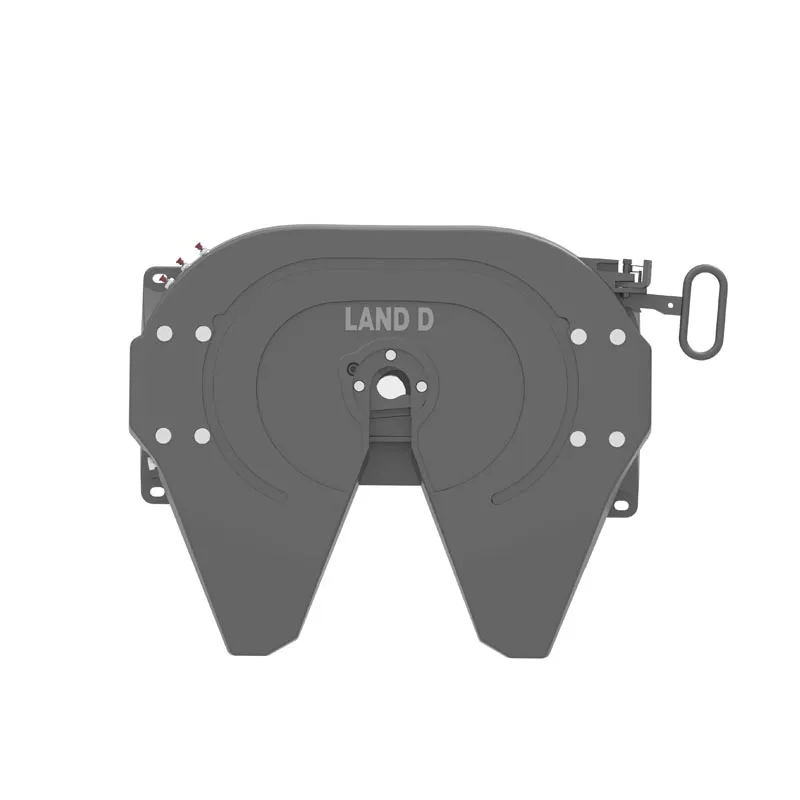

A semi kingpin is the pivotal part that connects the semi-trailer to the tractor. It is a steel pin that is mounted on the trailer, and it fits into the fifth wheel on the truck. The design allows for a pivoting motion, which is necessary for maneuverability, especially when navigating tight turns or backing up. The size of the kingpin can influence the overall handling and stability of the trailer, making the selection of the right dimension crucial for optimal performance.

Common Sizes and Standards

The most common semi kingpin sizes are typically categorized by the diameter of the pin and the height at which it is mounted on the trailer. The industry standard for kingpins is generally a diameter of 2.0 inches. However, there are variations that include 1.5 inches and 3 inches, primarily depending on the manufacturer and the specific requirements of the trailer.

The height of the kingpin is also crucial. Standard heights are usually around 18 inches from the ground to the top of the kingpin. Correct height ensures that the trailer aligns adequately with the tractor's fifth wheel, preventing excessive wear and potential accidents. Any misalignment can affect the center of gravity of the whole rig, leading to handling difficulties, especially when driving through adverse weather conditions or negotiating inclines.

Factors to Consider When Choosing a Kingpin Size

best semi kingpin size

When selecting a kingpin size, several factors warrant consideration

1. Trailer Type and Weight Different types of trailers (flatbeds, tankers, refrigerated units) may require specific kingpin sizes. Heavier loads might necessitate a more robust kingpin to handle the stress and strain put upon it.

2. Compatibility with the Fifth Wheel Ensure that the kingpin size matches the specifications of the tractor's fifth wheel. Mismatched sizes can lead to unsafe connections, resulting in increased wear or, worse, trailer detachment during transit.

3. Regulatory Compliance Be aware of local and federal regulations regarding towing configurations. Certain sizes and types may be mandated, especially when it comes to specific industries or cargo types.

4. Performance Requirements Think about the operational conditions the truck will face. Off-road conditions, frequent heavy hauls, or extended travel times may necessitate a higher-quality or differently-sized kingpin.

Conclusion

Choosing the best semi kingpin size is more than just selecting a part; it is about ensuring safety, compliance, and performance in transportation operations. By carefully considering the factors outlined above, trucking professionals can make informed decisions that enhance the overall functionality of their vehicles. Whether you are an owner-operator or a fleet manager, understanding the implications of kingpin size can lead to better road handling and, ultimately, a safer journey on the open road. Thus, investing time in selecting the right semi kingpin is imperative for any serious player in the trucking industry.

-

Imperial Truck Repair Hayward CA - High Quality, Affordable & Reliable Services

NewsJun.10,2025

-

High Quality Fontaine International do Brasil – Best Discount Offers Online

NewsJun.10,2025

-

Premium Fontaine Valves - High Quality & Discount Offers Durable

NewsJun.10,2025

-

Premium Fifth Wheel King Pins Top Durability & Savings

NewsJun.10,2025

-

Best Semi Trailer Kingpins for Sale Premium & Discounted

NewsJun.10,2025

-

Premium Holland Fifth Wheel Slider Parts Durable & Discount Deals

NewsJun.09,2025