11 月 . 07, 2024 21:08 Back to list

Explore the Innovative Design of Oakley Bracket Slide by Top Manufacturer

Understanding Oakley Bracket Slide Manufacturing

When it comes to performance eyewear, Oakley has consistently established itself as a leading brand in the industry. Among its many product offerings, the Oakley Bracket Slide stand out as an exceptional combination of style, functionality, and innovation. The manufacturing process behind these sunglasses is a testament to Oakley's commitment to quality and performance.

Oakley was founded in 1975 by Jim Jannard in California and has since evolved into a global powerhouse in the eyewear market. The Bracket Slide series exemplifies the brand's pursuit of excellence, catering primarily to athletes and outdoor enthusiasts who require durability and style in their eyewear. The manufacturing of these sunglasses is crucial to maintaining Oakley's reputation for quality, and it encompasses a variety of processes, materials, and technologies.

Materials Used in Manufacturing

The Oakley Bracket Slide sunglasses are crafted from high-quality materials that offer both durability and comfort. The frames are typically made from lightweight yet robust materials like O Matter™, which is a proprietary thermoplastic. This material is designed to withstand extreme conditions while providing flexibility and comfort, ensuring that the glasses fit snugly without compromising on wearability.

The lenses used in the Bracket Slide series often feature Plutonite® material, which blocks 100% of all UVA, UVB, and UVC rays. This innovative lens technology enhances visual clarity and reduces eye strain for those spending extended periods outdoors. Additionally, many models have anti-scratch and anti-fog coatings, ensuring optimal performance in various environmental conditions.

Advanced Manufacturing Techniques

The manufacturing process for the Oakley Bracket Slide involves advanced techniques and strict quality control measures. Each pair undergoes rigorous testing to ensure that they meet Oakley’s high standards for performance and durability. The manufacturing steps include

1. Design and Prototyping The design phase involves extensive research and development, with teams creating prototypes that undergo extensive field testing. Feedback from athletes and consumers shapes the final design, focusing on both aesthetics and functionality.

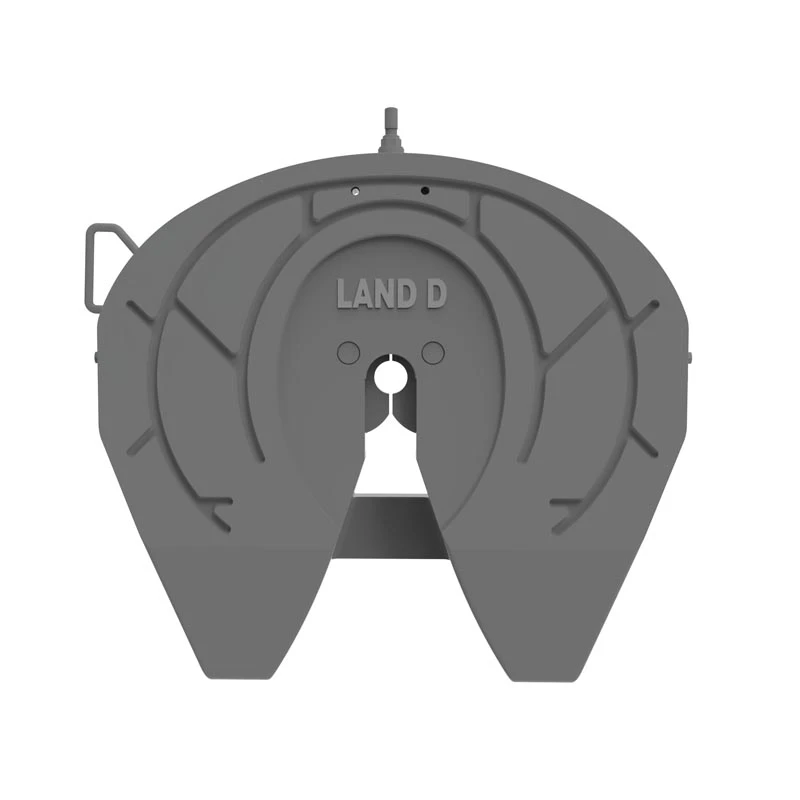

oakley bracket slide manufacturer

2. Injection Molding Oakley employs state-of-the-art injection molding techniques to create the frames of the sunglasses. This process allows for precise shaping and ensures consistent quality across large production runs.

3. Lens Production The lenses are manufactured using advanced optical technology that not only enhances clarity but also provides impact resistance. This is especially important for athletes who require eyewear that can withstand high-speed activities and potential impacts.

4. Assembly After the frames and lenses are produced, they are assembled in a clean environment to avoid contamination. Each component is meticulously checked for quality, ensuring that the final product meets Oakley’s standards.

5. Quality Control Testing Finally, each pair of sunglasses undergoes a series of quality control tests. These tests assess scratch resistance, impact resistance, and overall durability. Only those that pass these stringent tests are packaged and shipped to retailers.

Eco-Friendly Initiatives

Oakley is also committed to sustainability in its manufacturing process. The company has initiated steps to reduce its environmental footprint by implementing eco-friendly practices. This includes using recycled materials in packaging, reducing waste in production, and investing in renewable energy sources for manufacturing plants.

Conclusion

The Oakley Bracket Slide sunglasses represent the pinnacle of eyewear innovation, merging cutting-edge technology with high-quality materials and craftsmanship. The meticulous manufacturing process ensures that each pair is not only aesthetically pleasing but also enhances the performance and protection of the wearer. As Oakley continues to push the boundaries of eyewear design and technology, the Bracket Slide series remains a symbol of the brand’s dedication to excellence, catering to those who demand nothing less than the best in their eyewear—whether on the field, mountain, or urban landscape. Through continual innovation and sustainable practices, Oakley is poised to maintain its leadership in the competitive eyewear market for years to come.

-

Nuss Truck Sauk Rapids - High Quality, Best Deals & Discounts Available

NewsJul.08,2025

-

High Quality Kingpin Adalah – Best Kingpin Adalah for Trucks, Get Discount Kingpin Adalah Now!

NewsJul.08,2025

-

High Quality Fifth Wheel Bracket for Heavy Loads – Best Discount Deals Online

NewsJul.08,2025

-

High Quality Fifth Wheel Coupling System for Trucks Best Fifth Wheel Coupling System Online

NewsJul.07,2025

-

High Quality & Best Volvo Trucks in Kansas City Discount Volvo Trucks for Sale

NewsJul.07,2025

-

High Quality & Best Standard Height of Tractor Trailer – Discount Prices Available

NewsJul.07,2025