10 月 . 15, 2024 03:26 Back to list

Fifth Wheel Manufacturing for Semi-Tractor Trailers in the Automotive Industry

Understanding the Role of Fifth Wheel Factories in Semi-Tractor Manufacturing

In the complex world of transportation logistics, the semi-trailer truck is a pivotal player. Among its many components, the fifth wheel stands out as a critical piece of equipment, enabling the connection between the tractor unit and the trailer. This essential mechanism allows for articulation during transport, ensuring that the trailer can pivot when turning without losing stability. This article delves into the world of fifth wheel factories that manufacture this vital component, highlighting their significance in the trucking industry.

The Fifth Wheel A Vital Link

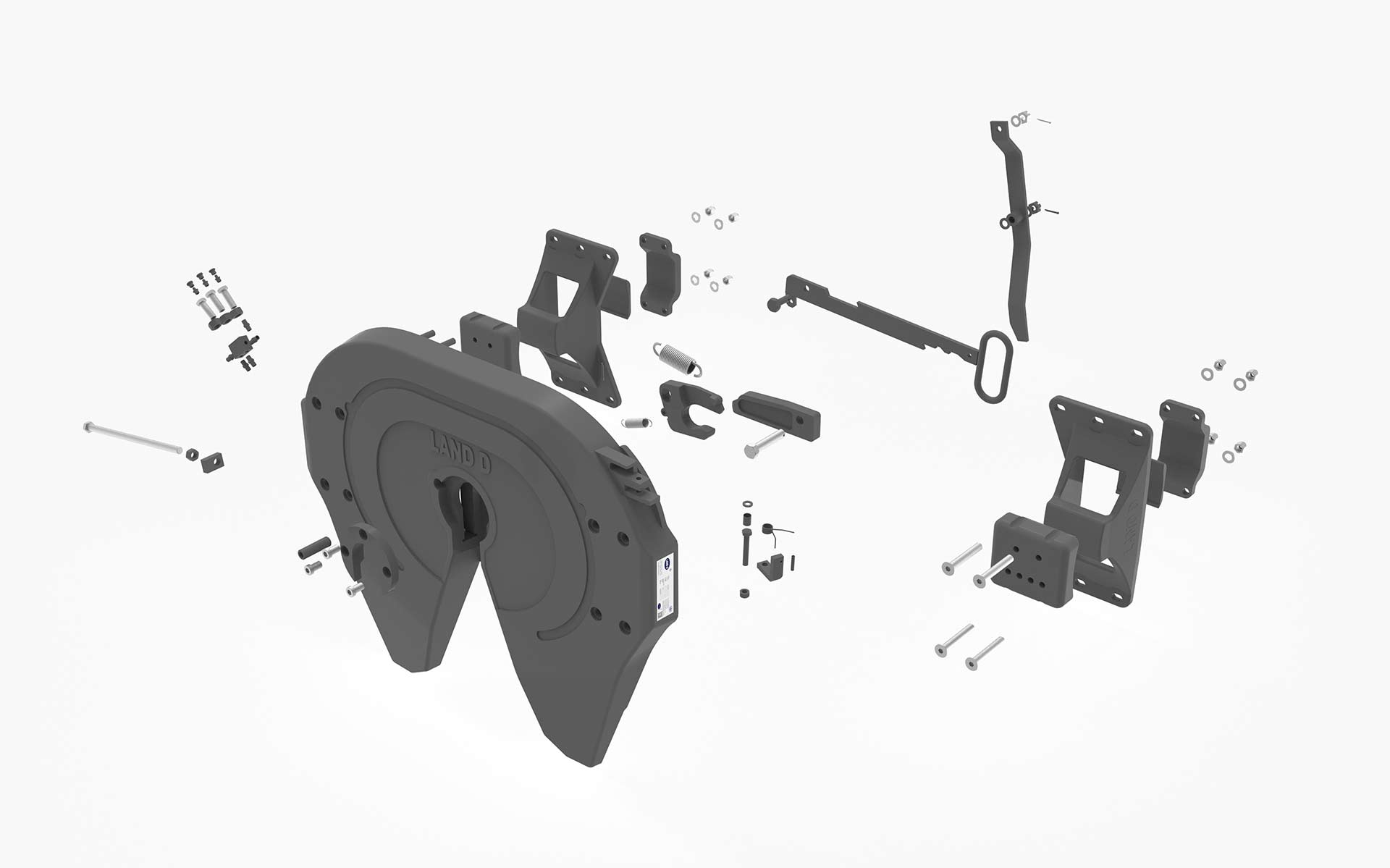

The fifth wheel is a crucial interface in heavy-duty vehicles, particularly in semi-trailer configurations. It consists of a horizontal plate mounted on the rear of the tractor that connects to the kingpin of the trailer. When properly installed, the fifth wheel allows for smooth and reliable hitching and unhitching of the trailer while permitting necessary mobility during transit.

Performance and durability are paramount for this component, as it must withstand significant stress and forces during operations. Given the high standards required, fifth wheel factories focus heavily on material quality, design specifications, and engineering excellence. They play an essential role in ensuring that the trucking industry operates efficiently and safely.

Manufacturing Processes in Fifth Wheel Factories

The manufacturing process of fifth wheels involves several stages, from design and engineering to production and quality assurance. Here’s a brief overview

1. Design and Engineering The first step in producing fifth wheels is rigorous design and engineering work, where engineers use computer-aided design (CAD) software to create models that meet specific performance standards. During this phase, considerations such as load capacity, weight distribution, ease of operation, and safety features are meticulously calculated.

2. Material Selection The choice of materials is critical; fifth wheels must be made of high-strength steels or other durable materials to ensure longevity and reliability under heavy loads. Factories often conduct material tests to ensure they meet industry standards.

semi tractor fifth wheel factories

3. Manufacturing Techniques Factories utilize advanced machining processes, including forging, casting, and welding, to create the components of the fifth wheel. CNC (Computer Numerical Control) machines allow for precision in shaping and finishing parts, resulting in a high-quality product.

4. Quality Control Quality assurance is integral throughout the manufacturing process. Factories implement stringent testing measures, including load testing and fatigue testing, to ensure each unit can handle the expected demands once in the field. This step ensures compliance with safety regulations and industry standards.

5. Assembly and Final Testing After manufacturing individual components, assemblies are formed, and final testing is conducted to verify performance and durability. Each fifth wheel is meticulously checked for alignment and functionality before being shipped to manufacturers or dealers.

Quality and Innovation in Fifth Wheel Factories

With the growing demand for enhanced performance and safety in trucking, innovation in fifth wheel design and technology is an ongoing endeavor in factories. Manufacturers are investing in research and development to create new features, such as lightweight designs for improved fuel efficiency, enhanced locking mechanisms for increased safety, and shock-absorbing systems to reduce wear on both the tractor and trailer.

Moreover, environmental considerations are becoming crucial, leading to the exploration of sustainable materials and manufacturing practices. Factories are progressively adopting eco-friendly processes to minimize their carbon footprint, reflecting a broader trend within the transportation industry.

Conclusion

Fifth wheel factories serve as the backbone of the semi-trailer truck industry. By producing high-quality, durable, and innovative fifth wheels, these factories ensure the safety and efficiency of freight transportation. As the industry continues to evolve with new technologies and regulations, the role of fifth wheel manufacturers will remain crucial. The ongoing commitment to quality, performance, and innovation will support the future of transportation logistics, marking the fifth wheel as an indispensable element in connecting goods across vast distances.

-

Nuss Truck Sauk Rapids - High Quality, Best Deals & Discounts Available

NewsJul.08,2025

-

High Quality Kingpin Adalah – Best Kingpin Adalah for Trucks, Get Discount Kingpin Adalah Now!

NewsJul.08,2025

-

High Quality Fifth Wheel Bracket for Heavy Loads – Best Discount Deals Online

NewsJul.08,2025

-

High Quality Fifth Wheel Coupling System for Trucks Best Fifth Wheel Coupling System Online

NewsJul.07,2025

-

High Quality & Best Volvo Trucks in Kansas City Discount Volvo Trucks for Sale

NewsJul.07,2025

-

High Quality & Best Standard Height of Tractor Trailer – Discount Prices Available

NewsJul.07,2025