4 月 . 24, 2025 13:41 返回目录

The Role of Materials in Fifth Wheel Coupling Design

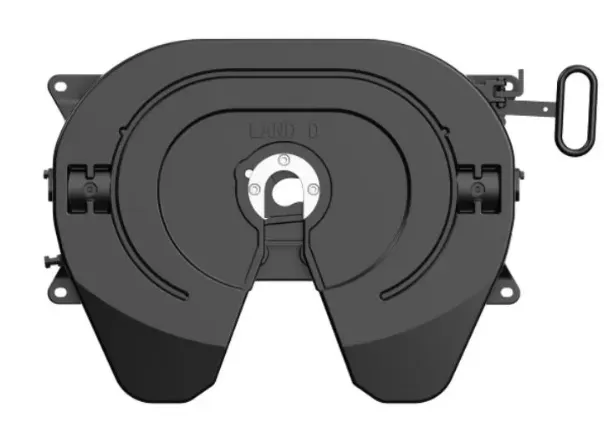

这 第五轮联轴器 is a crucial component in the trucking industry, enabling the secure attachment of trailers to trucks. The choice of materials in 第五轮联轴器组件 plays a significant role in ensuring durability, safety, and efficiency. From 5th wheel jaws to the overall coupling system, high-quality materials contribute to enhanced performance and longevity. This article explores the importance of materials in 第五轮联轴器, their impact on truck and trailer operations, and why material selection is critical for reliable transportation.

High-Strength Steel in Fifth Wheel Coupling Components

One of the most commonly used materials in 第五轮联轴器组件 is high-strength steel. This material offers:

- Exceptional Load-Bearing Capacity– The 第五轮联轴器 must withstand immense pressure and weight, making steel the ideal choice for its durability.

- Resistance to Wear and Tear– Frequent coupling and uncoupling generate friction, which steel components can endure without significant damage.

- Safety and Stability– Steel ensures that 5th wheel jaws maintain a secure grip on the trailer kingpin, preventing accidents caused by detachment.

Due to its high strength and toughness, steel remains the preferred material for critical truck & trailer components ltd uses in coupling systems.

F第五 Wheel Coupling Components: Alloy Enhancements for Improved Durability

While standard steel is strong, alloyed steel takes 第五轮联轴器组件 to the next level. Alloy enhancements improve:

- Corrosion Resistance– Exposure to moisture, road salts, and extreme weather conditions can cause rust and degradation. Alloyed steel resists corrosion better, extending the lifespan of 第五轮联轴器.

- Increased Fatigue Strength– Alloying elements like chromium and nickel enhance the toughness of 5th wheel jaws, allowing them to endure repetitive stress without failure.

- Weight Optimization– Some advanced alloys offer high strength while reducing overall weight, improving fuel efficiency in truck & trailer components ltd

Using alloyed materials in 第五轮联轴器 ensures longevity and dependable performance under tough operating conditions.

Composite Materials for Modern Fifth Wheel Couplings

While steel and alloys dominate 第五轮联轴器设计, modern innovations have introduced composite materials. These materials offer:

- Lightweight Construction– Composite materials reduce the weight of 第五轮联轴器组件, making trucks more fuel-efficient.

- Reduced Maintenance Needs– Composites are resistant to rust and corrosion, requiring less upkeep than traditional steel components.

- High-Impact Resistance– Certain composites can absorb shocks and vibrations better than metal, reducing wear on 5th wheel jaws and other coupling parts.

Though not yet widespread, composite materials are becoming more popular in truck & trailer components ltd manufacturing for their efficiency and performance benefits.

To further improve the strength and reliability of 第五轮联轴器, many manufacturers use heat-treated materials. The benefits include:

- Higher Load Capacity– Heat treatment enhances the strength of 5th wheel jaws, allowing them to support heavier trailers without deformation.

- Improved Toughness– Heat-treated steel resists cracking and breaking under stress, making it ideal for 第五轮联轴器组件.

- Better Friction Resistance– Heat treatment helps minimize wear caused by repeated engagement and disengagement of 第五轮联轴器.

By selecting heat-treated materials, truck & trailer components ltd ensures maximum durability and safety in their coupling systems.

The Role of Materials in Fifth Wheel Coupling Design: FAQs

What material is best for fifth wheel couplings?

High-strength steel is the most commonly used material due to its durability, load-bearing capacity, and resistance to wear and tear. Alloyed and heat-treated versions further improve performance.

Are composite materials reliable for fifth wheel coupling components?

Yes, composite materials offer lightweight construction, corrosion resistance, and high-impact strength, but they are not yet as widely used as steel.

How do 5th wheel jaws benefit from heat treatment?

Heat treatment strengthens the 5th wheel jaws, making them more resistant to stress, wear, and extreme loads, ensuring a secure truck-trailer connection.

Why is corrosion resistance important for truck & trailer components ltd couplings?

Corrosion-resistant materials extend the lifespan of 第五轮联轴器组件, reducing maintenance costs and improving long-term performance.

Where can I purchase high-quality fifth wheel couplings?

As a trusted foreign trade wholesaler, we offer durable 第五轮联轴器组件, including 5th wheel jaws and advanced materials for maximum performance. Visit our website today for reliable solutions!

-

Why Are Specialized Components Crucial in Commercial Vehicle Maintenance and Operation?

新闻Jul.28,2025

-

Why Are Fifth Wheels Critical for Trucking and How to Select the Right One?

新闻Jul.28,2025

-

What Defines the Excellence of American Trailer Components in Key Markets?

新闻Jul.28,2025

-

What Defines the Excellence of American 5th Wheel Systems and Their Market Offerings?

新闻Jul.28,2025

-

How Do 5th Wheel Trailers Redefine Towing and Living Standards?

新闻Jul.28,2025

-

How Do 5th Wheel Systems Enhance Commercial Hauling Efficiency and Versatility?

新闻Jul.28,2025