Jul . 16, 2025 17:09 Terug na lys

Unveiling the Essentials of Fifth Wheel Components in Commercial Transport

In the realm of heavy - duty transportation, the seamless integration of tractor and trailer relies on specialized components designed for safety, durability, and efficiency. Among these, the fifth wheel puller, fifth wheel plates for semi - trucks, vyfde wiel plaat, fifth wheel pin, and fifth wheel mounting brackets play pivotal roles in ensuring secure connections and optimal performance. Understanding their functions, maintenance, and installation is crucial for fleet managers, mechanics, and operators alike.

The Role of Fifth Wheel Puller in Maintenance

Tools like the fifth wheel puller are essential for safely removing and installing these heavy - duty components. When a fifth wheel plate or mounting bracket needs replacement due to wear or damage, a fifth wheel puller helps detach the unit from the tractor frame without causing additional stress or deformation. This tool typically uses hydraulic or mechanical force to evenly lift and separate the fifth wheel assembly, minimizing the risk of injury or equipment damage. For example, during routine inspections, if a vyfde wiel plaat shows signs of cracks or excessive corrosion, a fifth wheel puller enables mechanics to efficiently remove the old component and install a new one, ensuring minimal downtime for the vehicle.

Functionality of Fifth Wheel Plates for Semi - Trucks

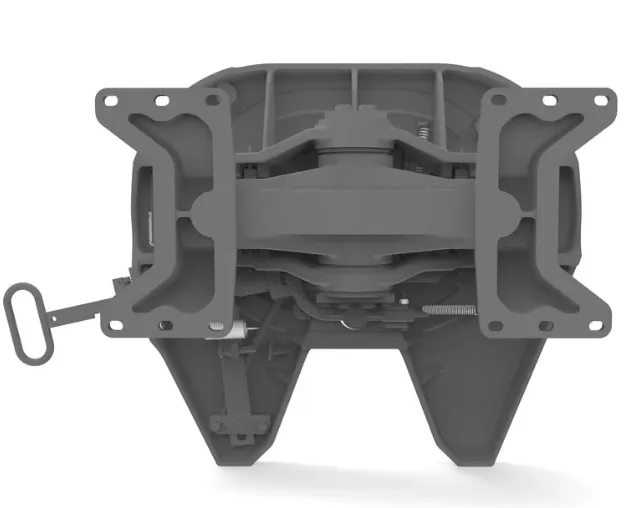

Fifth wheel plates for semi - trucks serve as the foundational interface between the tractor and trailer. These robust plates, often made from high - strength steel, feature a curved surface that cradles the trailer’s kingpin, allowing for smooth articulation during turns while bearing the trailer’s weight. A vyfde wiel plaat is equipped with a locking mechanism that secures the kingpin (or fifth wheel pin) in place, preventing accidental detachment during transit. In long - haul operations, the plate’s design must withstand constant vibrations, heavy loads, and varying road conditions. Regular lubrication of the vyfde wiel plaat and inspection of its locking components are vital to maintaining a secure connection and reducing wear on the fifth wheel pin.

Importance of Fifth Wheel Pin in Coupling Systems

The fifth wheel pin, also known as the kingpin, is a critical component on the trailer that connects to the tractor’s fifth wheel plate. Typically forged from alloy steel, the fifth wheel pin is designed to endure high vertical and horizontal forces. It fits into the horseshoe - shaped slot of the vyfde wiel plaat, and when locked, creates a rigid connection between the two units. Proper alignment and maintenance of the fifth wheel pin are essential; a bent or worn pin can lead to unstable coupling, increased trailer sway, or even complete detachment. Mechanics must regularly check the pin for signs of deformation, cracks, or excessive play, as these issues can compromise the safety of the entire transport system.

Design and Installation of Fifth Wheel Mounting Brackets

Fifth wheel mounting brackets provide the structural support needed to attach the fifth wheel plate to the tractor’s frame. These brackets are engineered to distribute the trailer’s weight evenly across the tractor, reducing stress on the frame and ensuring balanced load transfer. Made from durable materials like carbon steel or aluminum, fifth wheel mounting brackets come in various designs to accommodate different tractor models and fifth wheel plate sizes. During installation, precise alignment of the brackets is crucial to ensure the fifth wheel plate sits level and secure. Any misalignment can lead to uneven wear on the vyfde wiel plaat or fifth wheel pin, potentially causing operational inefficiencies or safety hazards.

FAQ: Key Insights into Fifth Wheel Components

How to Choose the Right Fifth Wheel Puller for My Needs?

When selecting a fifth wheel puller, consider the weight and size of your fifth wheel assembly, as well as the type of force mechanism (hydraulic vs. mechanical). Hydraulic pullers offer greater power for heavy - duty applications, while mechanical options may suffice for lighter units. Look for models with adjustable arms to fit different mounting bracket configurations and ensure the tool is compatible with your tractor’s make and model. Always prioritize safety features like load - bearing capacity ratings and stable bases to prevent accidents during use.

What Maintenance Practices Extend the Life of Fifth Wheel Plates?

Regularly lubricate the surface of the vyfde wiel plaat and the area around the fifth wheel pin to reduce friction and wear. Use a high - temperature grease suitable for heavy - duty applications. Inspect the plate for cracks, dents, or uneven wear, especially around the locking mechanism. Clean debris and dirt from the plate’s surface to prevent abrasive damage. Additionally, check the tightness of the fifth wheel mounting brackets to ensure the plate remains securely attached to the tractor frame.

Can I Install Fifth Wheel Mounting Brackets Without Professional Help?

While experienced mechanics may handle installation, it’s recommended to have fifth wheel mounting brackets installed by professionals. Proper installation requires precise alignment using specialized tools and adherence to manufacturer specifications. Incorrectly installed brackets can lead to misalignment of the fifth wheel plate, causing excessive stress on the fifth wheel pin and potential safety risks. Always refer to the tractor and bracket manufacturer’s guidelines or consult a certified technician for installation.

What Are the Signs of a Worn Fifth Wheel Pin?

A worn fifth wheel pin may show signs such as visible grooves, uneven wear, or a loose fit within the fifth wheel plate’s locking mechanism. You might notice increased trailer sway, unusual noises during turns, or difficulty coupling/uncoupling the trailer. If the pin’s diameter has reduced due to wear, it may no longer fit securely, compromising the connection. Regular visual inspections and dimensional checks against manufacturer standards can help identify when a fifth wheel pin needs replacement.

How Do Fifth Wheel Mounting Brackets Affect Tractor Performance?

Well - designed fifth wheel mounting brackets ensure the fifth wheel plate is positioned correctly, allowing for proper weight distribution and smooth articulation. Misaligned or damaged brackets can cause uneven load distribution, leading to increased tire wear, reduced fuel efficiency, and stress on the tractor’s suspension system. They also impact the trailer’s stability during turns, potentially increasing the risk of jackknifing. Maintaining the integrity of the fifth wheel mounting brackets is essential for overall vehicle performance and safety.

-

What Defines Excellence in Fifth Wheel Components and Their Manufacturers?

NuusJul.16,2025

-

Unveiling the Essentials of Fifth Wheel Systems in Heavy - Haul Transportation

NuusJul.16,2025

-

Unveiling the Essentials of Fifth Wheel Components in Commercial Transport

NuusJul.16,2025

-

Unveiling the Essence of Holland 5th Wheel Systems

NuusJul.16,2025

-

Unveiling the Dominance and Features of Holland Fifth Wheels

NuusJul.16,2025

-

Discovering the Diverse Landscape of Truck - Related Services and Offerings

NuusJul.16,2025