- አፍሪካዊ

- አልበንያኛ

- አማርኛ

- አረብኛ

- አርመንያኛ

- አዘርባጃኒ

- ባስክ

- ቤላሩሲያን

- ቤንጋሊ

- ቦስንያን

- ቡልጋርያኛ

- ካታሊያን

- ሴቡአኖ

- ቻይና

- ቻይና (ታይዋን)

- ኮርሲካን

- ክሮኤሽያን

- ቼክ

- ዳኒሽ

- ደች

- እንግሊዝኛ

- እስፔራንቶ

- ኢስቶኒያን

- ፊኒሽ

- ፈረንሳይኛ

- ፍሪሲያን

- ጋላሺያን

- ጆርጅያን

- ጀርመንኛ

- ግሪክኛ

- ጉጅራቲ

- ሓይቲያን ክሬኦሌ

- ሃውሳ

- ሐዋያን

- ሂብሩ

- አይደለም

- ሚያኦ

- ሃንጋሪያን

- አይስላንዲ ክ

- igbo

- ኢንዶኔዥያን

- አይሪሽ

- ጣሊያንኛ

- ጃፓንኛ

- ጃቫኒስ

- ካናዳ

- ካዛክሀ

- ክመር

- ሩዋንዳኛ

- ኮሪያኛ

- ኩርዲሽ

- ክይርግያዝ

- የጉልበት ሥራ

- ላቲን

- ላትቪያን

- ሊቱኒያን

- ሉክዜምብርጊሽ

- ማስዶንያን

- ማልጋሺ

- ማላይ

- ማላያላም

- ማልትስ

- ማኦሪይ

- ማራቲ

- ሞኒጎሊያን

- ማይንማር

- ኔፓሊ

- ኖርወይኛ

- ኖርወይኛ

- ኦሲታን

- ፓሽቶ

- ፐርሽያን

- ፖሊሽ

- ፖርቹጋልኛ

- ፑንጃቢ

- ሮማንያን

- ራሺያኛ

- ሳሞአን

- ስኮትላንዳዊ ጌሊክ

- ሰሪቢያን

- እንግሊዝኛ

- ሾና

- ስንድሂ

- ሲንሃላ

- ስሎቫክ

- ስሎቬንያን

- ሶማሊ

- ስፓንኛ

- ሱዳናዊ

- ስዋሕሊ

- ስዊድንኛ

- ታንጋሎግ

- ታጂክ

- ታሚል

- ታታር

- ተሉጉ

- ታይ

- ቱሪክሽ

- ቱሪክሜን

- ዩክሬንያን

- ኡርዱ

- ኡጉር

- ኡዝቤክ

- ቪትናሜሴ

- ዋልሽ

- እገዛ

- ዪዲሽ

- ዮሩባ

ነሐሴ . 28, 2025 00:20 ወደ ዝርዝር ተመለስ

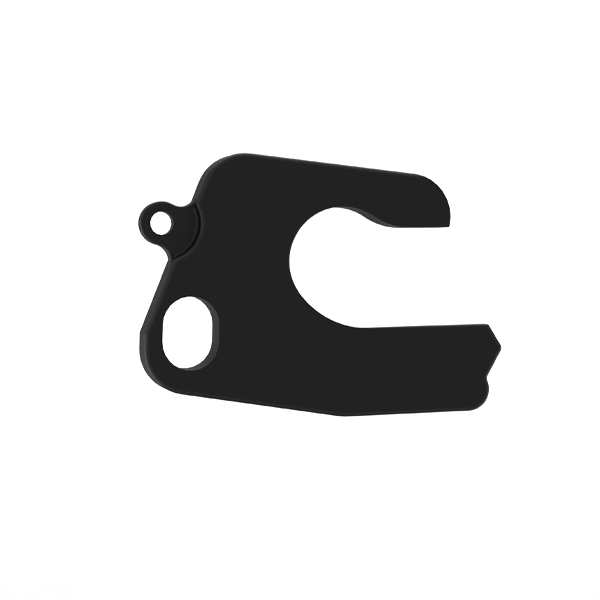

Durable 5th Wheel Bumper Kit for Enhanced Safety & Storage

In the demanding world of heavy-duty transportation, the integrity and reliability of every component are paramount. Among these, the 5ኛ የጎማ መከላከያ ኪት stands as a critical safety and operational element. These kits are not merely accessories; they are integral systems designed to protect the fifth wheel coupling from external impacts, extend its service life, and ensure the secure attachment between tractor and trailer. For B2B decision-makers and engineering professionals, understanding the intricate details, manufacturing precision, and application benefits of these components is essential for optimizing fleet performance and safety.

Industry Trends in Heavy-Duty Trailer Components

The heavy-duty transportation sector is currently undergoing significant transformation, driven by advancements in materials science, manufacturing technologies, and evolving regulatory landscapes. Key trends impacting components like the 5ኛ የጎማ መከላከያ ኪት include a strong emphasis on lightweighting for improved fuel efficiency, the integration of smart technologies for enhanced safety and predictive maintenance, and an unwavering demand for increased durability and corrosion resistance. The market for these specialized components is projected to grow steadily, with an increasing focus on integrated systems that reduce installation time and overall maintenance costs.

Specific trends include the adoption of advanced high-strength steels and composite materials to achieve weight reductions without compromising structural integrity. Furthermore, there's a growing demand for components that can withstand extreme operating conditions, from the harsh environments faced by a 5ኛ የጎማ መጣል ተጎታች to the continuous long-haul operations that necessitate robust jost fifth wheel systems. Manufacturers are also developing more sophisticated testing protocols to ensure products meet increasingly stringent safety and performance benchmarks.

Manufacturing Process Flow of the 5th Wheel Bumper Kit

The production of a high-quality 5ኛ የጎማ መከላከያ ኪት is a multi-stage process demanding meticulous precision, robust material selection, and adherence to stringent quality control standards. This ensures components can endure the significant stresses of heavy-duty applications.

1. Design and Engineering

- CAD/CAM Development: Utilizing advanced Computer-Aided Design and Manufacturing software to create precise 3D models and manufacturing instructions.

- Finite Element Analysis (FEA): Simulating real-world stress and strain conditions to optimize structural integrity, identify potential failure points, and ensure design robustness under maximum load.

2. Material Sourcing and Preparation

- High-Strength Alloys: Primary materials include high-grade steel alloys such as ASTM A514 (for exceptional strength-to-weight ratio), AISI 4130 chromoly steel (for toughness), and specialized ductile irons for certain cast components. These materials are selected for their superior mechanical properties, including high tensile strength, fatigue resistance, and impact absorption.

- Quality Verification: All incoming materials undergo rigorous testing for chemical composition and mechanical properties to ensure compliance with specified standards (e.g., ASTM, EN).

3. Core Manufacturing Processes

- Forging/Casting: Critical load-bearing components may be forged for maximum strength and grain structure optimization or cast from ductile iron for complex geometries with excellent shock absorption.

- CNC Machining: Precision machining ensures tight tolerances for all mating surfaces and critical dimensions. This stage is crucial for the perfect fit and function of the 5 ኛ ጎማ ሳህን and related components.

- Welding: Robotic and manual welding (MIG, TIG) processes are employed, following certified welding procedures (e.g., AWS D1.1). Weld integrity is verified through Non-Destructive Examination (NDE) methods like ultrasonic or magnetic particle inspection.

4. Surface Treatment and Finishing

- Corrosion Protection: Components undergo surface treatments such as powder coating (for durable chemical and abrasion resistance), galvanizing (for superior corrosion protection in marine or highly corrosive environments), or phosphating (as a base for further painting and improved adhesion). These treatments are vital for components like the 5ኛ የጎማ መከላከያ ኪት, which are exposed to harsh weather and road conditions.

5. Assembly and Quality Control

- Component Assembly: Using high-grade fasteners and specialized tooling to assemble the various parts of the kit.

- Testing Standards: Each 5ኛ የጎማ መከላከያ ኪት undergoes rigorous testing. This includes dimensional inspections to ISO 2768 standards, load testing (static and dynamic), and fatigue testing to simulate millions of operational cycles. Compliance with industry standards like ISO 9001 (Quality Management System) and relevant ANSI standards (e.g., ANSI B11.1-2009 for machine safety) is strictly maintained.

- Service Life Expectation: Designed for an operational service life typically ranging from 5 to 10 years or exceeding 1 million coupling cycles under normal operating conditions, contingent on proper maintenance and usage.

Target Industries and Application Advantages

Our 5ኛ የጎማ መከላከያ ኪትs are engineered for versatility across a wide array of heavy-duty industries:

- Petrochemical: Ensuring secure transport of hazardous materials, where reliability and corrosion resistance are non-negotiable.

- Metallurgy: Withstanding abrasive conditions and heavy loads common in metal transport.

- Construction: Providing robust performance for construction equipment and material haulage.

- Water Supply & Drainage: Supporting infrastructure projects with reliable equipment transport.

- Logistics & General Freight: Enhancing operational efficiency and safety for diverse cargo.

The technical advantages in these scenarios are significant, including enhanced safety due to superior impact protection, reduced operational downtime from fewer repairs, and superior corrosion resistance extending the lifespan of the entire fifth wheel assembly, leading to substantial energy and cost savings over the equipment's lifetime.

Technical Specifications and Parameters: JOST TAPE Fifth Wheel 37C Repair Kits

Our JOST TAPE Fifth wheel 37C repair kits are engineered to restore the optimal performance and safety of jost fifth wheel systems. These kits contain critical 5 ኛ ጎማ መሰኪያ ክፍሎች, meticulously manufactured to exact OEM specifications to ensure perfect fit and functionality, thereby extending the life of your existing fifth wheel assembly. Understanding the precise specifications is crucial for compatibility and performance assurance.

| Parameter | Specification |

|---|---|

| Product Model | JOST TAPE Fifth Wheel 37C Repair Kit |

| Compatibility | Specifically designed for JOST JSK 37C series fifth wheel hitches |

| Key Components Included | Locking jaws, wear plates, rubber cushions, pins, bushings, springs, operating handle components (exact contents may vary by kit configuration) |

| Material (Locking Jaws/Pins) | Forged high-strength alloy steel (e.g., 42CrMo4 equivalent), heat-treated for optimal hardness and wear resistance |

| Material (Wear Plates) | High-density, low-friction polymer composites (e.g., UHMW-PE) or hardened steel, designed for specific frictional properties and extended life |

| Surface Treatment | Phosphate coating, zinc plating, or rust-inhibiting finishes on metal components for corrosion resistance |

| Operating Temperature Range | -40°C to +80°C (-40°F to +176°F) |

| Compliance Standards | Meets or exceeds SAE J2228, ECE R55, and ISO 3842 standards for fifth wheel couplings and components. Manufactured under ISO 9001 certified processes. |

| Typical Service Life Extension | Up to 70-80% of original fifth wheel's design life with proper installation and maintenance |

Application Scenarios and Case Studies

The robust design and precision engineering of our 5ኛ የጎማ መከላከያ ኪት make it indispensable across diverse and challenging operational environments. These applications underscore the critical role of superior component quality in ensuring operational continuity and driver safety.

Scenario 1: Long-Haul Freight Operations

A major logistics firm operating a fleet of 500 trucks experienced frequent wear and tear on their fifth wheel coupling mechanisms due to high mileage and varied terrain. Implementing our advanced 5ኛ የጎማ መከላከያ ኪትs across their fleet resulted in a documented 25% reduction in unplanned maintenance events related to fifth wheel damage over a 12-month period. The enhanced impact protection and wear resistance of the kits significantly prolonged the life of the primary fifth wheel assemblies, contributing to a 15% improvement in overall fleet uptime.

Scenario 2: Heavy-Duty Construction Transport

For a construction company specializing in moving heavy machinery and oversized loads, ensuring a secure and stable connection is paramount. Their 5ኛ የጎማ መጣል ተጎታች operations often involve uneven ground and dynamic loading conditions. By upgrading to our heavy-duty 5ኛ የጎማ መከላከያ ኪት, they reported a marked increase in driver confidence and a complete elimination of coupling plate deformation issues that previously led to expensive repairs and project delays. The robust construction of the kit also provided superior protection against debris and minor collisions common on construction sites.

Customer Feedback Snapshot:

- "The durability of these bumper kits is exceptional. We've seen a noticeable reduction in the need for 5 ኛ ጎማ መሰኪያ ክፍሎች replacements since installation." - Fleet Manager, Acme Logistics Inc.

- "Reliability is key in our oilfield operations. The robust construction of the 5ኛ የጎማ መከላከያ ኪት provides the peace of mind we need for critical hauls." - Operations Director, Apex Energy Transport.

Technical Advantages of Advanced 5th Wheel Bumper Kit Systems

Modern 5ኛ የጎማ መከላከያ ኪት designs incorporate several key technical advantages that significantly enhance performance, safety, and cost-efficiency for fleet operators:

- Superior Durability and Fatigue Resistance: Utilizing advanced heat-treated alloy steels and robust welding techniques, these kits are engineered to withstand millions of dynamic load cycles and significant shock impacts, far exceeding the lifespan of standard components. This directly translates to less frequent replacements of 5 ኛ ጎማ መሰኪያ ክፍሎች.

- Enhanced Safety Mechanisms: Integrated design features provide improved protection for critical fifth wheel locking mechanisms, safeguarding against accidental uncoupling and minimizing damage during tight maneuvers or minor impacts. This contributes to overall operational safety, especially when dealing with complex setups like a 5 ኛ ጎማ ማቆሚያ.

- Reduced Maintenance Requirements: Through advanced coatings (e.g., low-friction, high-wear polymers) and precision manufacturing, our kits minimize friction and wear on contacting surfaces. This reduces the need for frequent lubrication and replacement of wear-prone parts, lowering operational expenditure.

- Weight Optimization for Fuel Efficiency: Strategic material selection and optimized design reduce unnecessary weight without compromising strength. A lighter 5ኛ የጎማ መከላከያ ኪት contributes to a lower overall vehicle weight, leading to improved fuel economy and increased payload capacity.

- Broad Compatibility and Versatility: Engineered to be compatible with a wide range of fifth wheel models, including popular jost fifth wheel designs and various trailer types (from standard freight to specialized 5ኛ የጎማ መጣል ተጎታችs), ensuring seamless integration into diverse fleets.

Vendor Comparison and Selection Criteria

Selecting the right supplier for a 5ኛ የጎማ መከላከያ ኪት involves more than just price; it requires a comprehensive evaluation of product quality, technical support, and long-term value. Decision-makers should consider the following critical criteria:

- Quality Certifications: Look for manufacturers holding ISO 9001, IATF 16949 (for automotive sector relevance), and relevant product-specific certifications (e.g., ECE R55).

- Material Traceability and Quality: Ensure the vendor provides full traceability of materials, backed by material test reports.

- Engineering and Customization Capabilities: Assess the vendor's ability to provide customized solutions for unique fleet requirements, including specialized materials or configurations.

- After-Sales Support and Warranty: Evaluate the comprehensiveness of warranty terms, availability of spare parts (e.g., 5 ኛ ጎማ መሰኪያ ክፍሎች), and technical support responsiveness.

- Lead Time and Fulfillment: Reliable delivery schedules are critical for minimizing operational downtime and managing inventory efficiently.

- Cost-Effectiveness vs. Price: Focus on the total cost of ownership, factoring in durability, maintenance, and longevity, rather than just the initial purchase price, especially when considering a 5 ኛ ጎማ መሰኪያ ለሽያጭ.

Comparison of Key Vendor Attributes

| Attribute | Our Offering (Example) | Typical Competitor (Hypothetical) |

|---|---|---|

| Certifications | ISO 9001, IATF 16949, ECE R55 compliant | Basic ISO 9001 |

| Material Quality | Forged high-strength alloy steel, fully traceable | Standard cast steel, limited traceability |

| Customization | Full engineering support for bespoke solutions | Limited to minor modifications of existing products |

| Warranty Period | 2-year comprehensive warranty | 1-year standard warranty |

| Lead Time (Standard Orders) | 2-4 weeks | 4-6 weeks |

| Technical Support | Dedicated engineering support, 24/7 online assistance | Standard business hours support |

Customized Solutions for Specialized Needs

Understanding that off-the-shelf solutions may not always meet the unique challenges of every heavy-duty application, we offer comprehensive customized solutions for our 5ኛ የጎማ መከላከያ ኪትs. Our engineering team collaborates closely with clients to develop bespoke configurations that address specific operational demands, environmental factors, and integration requirements. This includes:

- Material Adaptations: For extreme temperatures, corrosive agents (e.g., saltwater for coastal operations, chemicals in specialized transport), or exceptionally high-impact scenarios, we can specify alternative high-performance alloys or composite materials.

- Unique Mounting Configurations: Tailored mounting brackets and attachment points to integrate seamlessly with non-standard chassis designs or specialized trailer connections, ensuring optimal 5 ኛ ጎማ ቦታment.

- Specialized Coatings: Application of anti-friction, anti-corrosion, or extreme-temperature-resistant coatings to specific components to extend service life in highly aggressive environments.

- Integrated Sensor Systems: Development of kits with pre-drilled or integrated sensor mounts for compatibility with advanced telematics and predictive maintenance systems, offering real-time monitoring of impact forces or wear levels.

Our design flexibility and engineering expertise ensure that even the most complex requirements for 5ኛ የጎማ መከላከያ ኪትs can be met with precision and unwavering quality.

Ensuring Quality: Certifications and Trust

Our commitment to manufacturing excellence is underpinned by adherence to global quality standards and robust certifications. We understand that trust in B2B relationships is built on verifiable quality and consistent performance.

- ISO 9001:2015 Certified: Our entire manufacturing process, from design to delivery, operates under an ISO 9001 certified Quality Management System, ensuring consistent product quality and continuous improvement.

- Adherence to ECE R55: Our products meet the stringent requirements of ECE R55, the United Nations regulation concerning the approval of mechanical coupling components of combinations of vehicles.

- Extensive Industry Experience: With over two decades of dedicated service in the heavy-duty components sector, our expertise is built on years of research, development, and real-world application.

- Trusted Partnerships: We are proud to be a supplier to leading original equipment manufacturers (OEMs) and major fleet operators globally, testament to our reliability and product quality.

Frequently Asked Questions (FAQ)

Q: What is the typical lifespan of a 5ኛ የጎማ መከላከያ ኪት?

A: With proper installation, regular inspection, and maintenance, our 5ኛ የጎማ መከላከያ ኪትs are designed to provide robust protection for 5-10 years, or up to 1 million coupling cycles, extending the lifespan of the primary fifth wheel assembly significantly.

Q: How often should a 5ኛ የጎማ መከላከያ ኪት be inspected?

A: We recommend a visual inspection during routine vehicle maintenance, typically every 3-6 months or at specified mileage intervals, to check for any signs of wear, damage, or loose fasteners. Detailed inspections should be part of annual maintenance checks.

Q: Can these kits be customized for specific trailer types or operating conditions?

A: Absolutely. We offer extensive customization options, including material modifications, specialized coatings, and unique mounting configurations, to meet precise client requirements and challenging operational environments. Our engineering team is available for consultation.

Q: What safety standards do your products meet?

A: Our products are designed and tested to meet or exceed international standards such as ECE R55, SAE J2228, and ISO 3842, ensuring highest levels of safety and performance. Our manufacturing is ISO 9001 certified.

Logistics, Warranty, and Customer Support

Lead Time and Fulfillment

We maintain optimized production schedules and inventory management to ensure timely delivery. Standard orders for our JOST TAPE Fifth wheel 37C repair kits typically have a lead time of 2-4 weeks, depending on order volume and specific customization requirements. Expedited shipping options are available upon request to meet urgent operational needs.

Warranty Commitments

All our 5ኛ የጎማ መከላከያ ኪትs come with a comprehensive 2-year limited warranty against manufacturing defects in materials and workmanship. This warranty underscores our confidence in the quality and durability of our products, ensuring peace of mind for our clients.

የደንበኛ ድጋፍ

Our dedicated customer support team and technical experts are available to assist with product selection, installation guidance, and troubleshooting. We provide accessible channels for support, ensuring that our clients receive prompt and knowledgeable assistance whenever required. Technical documentation, including detailed installation guides and maintenance schedules, is also available.

Conclusion

The selection of a high-performance 5ኛ የጎማ መከላከያ ኪት is a strategic decision for any fleet operator or heavy-duty transport professional. Beyond merely offering protection, these meticulously engineered components contribute significantly to operational efficiency, driver safety, and the longevity of valuable equipment. By investing in products that adhere to rigorous manufacturing standards, leverage advanced materials, and are backed by comprehensive support, businesses can ensure optimal performance and achieve substantial long-term savings. Our commitment to quality, innovation, and client-centric solutions makes us a trusted partner in navigating the complexities of heavy-duty trailer component requirements.

References:

- ISO 9001:2015 Quality management systems – Requirements. International Organization for Standardization.

- ECE Regulation No. 55: Uniform provisions concerning the approval of mechanical coupling components of combinations of vehicles. United Nations Economic Commission for Europe.

- SAE J2228: Fifth Wheel Coupling Pin and Body – Heavy Duty Trucks. Society of Automotive Engineers.

- ASTM A514/A514M: Standard Specification for High-Yield-Strength, Quenched and Tempered Alloy Steel Plate, Suitable for Welding. ASTM International.

- Trucking Efficiency Council. Fuel Economy Best Practices Guide. North American Council for Freight Efficiency.

-

Durable 5th Wheel Bumper Kit for Enhanced Safety & Storage

ዜናAug.28,2025

-

Jost Fifth Wheel Weight Capacity Explained

ዜናAug.23,2025

-

Preventing Rust on Fifth Wheel Plates for Semi-Trucks

ዜናAug.23,2025

-

Light Weight Fifth Wheel Tire Care Guide

ዜናAug.23,2025

-

Why Off-road Trailers Need a Heavy Duty Fifth Wheel

ዜናAug.23,2025

-

Step-by-Step Guide to Lubricating Holland 5th Wheel Parts

ዜናAug.23,2025