jul. . 26, 2025 01:01 Back to list

American Type Welding Series Suspension - Durable Industrial Solution

Presented by Shijiazhuang Land Auto Component Ltd.

Website: https://www.landfifthwheel.com

Contact: Tel: +86 13091005279 | Mobile: 13091005279 | E-mail: info@land-d.cn

Address: Shijiazhuang City, Hebei Province, CHINA

Introduction: The DNA of Robustness — American Type Welding Series Suspension

In a rapidly evolving logistics landscape, heavy-duty trailers demand uncompromising quality and reliability. The American Type Welding Series Suspension emerges as a gold standard for trailer stability, load distribution, and lifecycle cost-effectiveness. Offered by Shijiazhuang Land Auto Component Ltd., this product line demonstrates superior welding technology, optimized technical parameters, and adaptability for an array of industrial and transportation scenarios. This article delves into the industry trends, technical details, parameters comparison, and specific applications that define the American Type Welding Series Suspension.

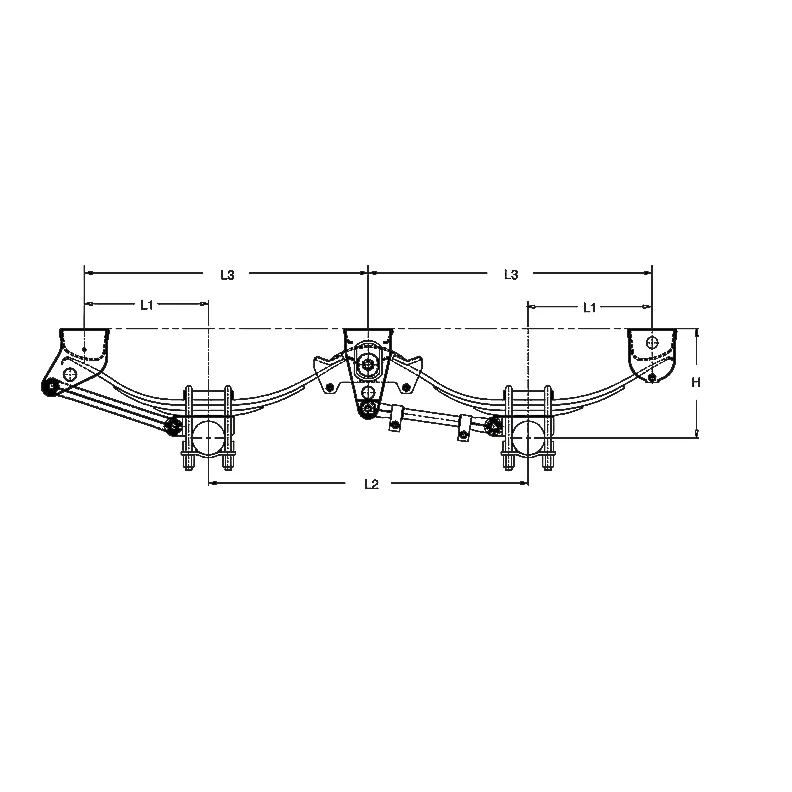

Product Overview: American Type Welding Series Suspension

The American Type Welding Series Suspension is engineered to meet the rigorous demands of North American standard heavy-duty vehicle applications. Utilizing a robust welded structure instead of riveted joints, these suspensions offer superior fatigue resistance, ease of maintenance, and enhanced driving comfort under diverse road conditions.

Visit the American Type Welding Series Suspension page for comprehensive technical details.

- Product Name: American Type Welding Series Suspension

- Manufacturer: Shijiazhuang Land Auto Component Ltd.

- Website: https://www.landfifthwheel.com/american-type-welding-series-suspension.html

- Applications: Heavy-duty semi-trailers, tanker trailers, flatbeds, container111 transport, and off-road logistics solutions.

- Main Strengths: Durability, weld integrity, high load-bearing capacity, and modular compatibility.

Industry Trends: Why American Type Welding Series Suspension is Leading the Way

The transport industry prioritizes safety, efficiency, and lifecycle costs. Recent studies from the Trailer Body Builders' Journal and Transport Topics highlight how weld-constructed suspension systems are rapidly replacing bolted or riveted counterparts due to their resilience, reduced maintenance frequency, and improved load balance (source).

American Type Welding Series Suspension sets itself apart with its compliance to American DOT and SAE standards, high-tensile steel construction, and excellent adaptability to air and mechanical axle systems (source).

Technical Data Table: Core Parameters of American Type Welding Series Suspension

| Model | Capacity (tons) | Main Material | Axle Spacing (mm) | Leaf Spring Size (mm) | Weight (kg) | Axle Connection | Welding Standard |

|---|---|---|---|---|---|---|---|

| Land-ATW13 | 13 | Q345/16Mn | 1270 | 90x13x1500 | 180 | Bolt-on Clamp | ISO 3834-2 |

| Land-ATW16 | 16 | Q345 | 1350 | 100x16x1500 | 205 | Weld-on | AWS D1.1 |

| Land-ATW20 | 20 | 16Mn | 1500 | 120x20x1550 | 280 | Weld-on Plate | AWS D1.1 |

| Land-ATW25HD | 25 | Q355 | 1550 | 130x24x1600 | 330 | Bolt-on / Welded | ISO 3834-2 |

Application Scenarios & Advantages

The American Type Welding Series Suspension proves indispensable in the following core sectors:

- Long-Haul Freight: Ensuring high operational uptime and reduced maintenance throughout extended journeys.

- Container Transportation: Optimized axle and suspension spacing for multi-modal requirement compliance.

- Tankers & Bulk Cargo: High-load resistance and fatigue durability under cyclical loading situations.

- Engineering & Mining Vehicles: Withstands rough terrains thanks to premium welded joints and superior material strength.

- Customizable Solutions: Designed for both OEMs and end-users requiring bespoke length, material, and spring specifications.

EEAT Optimization: Expertise, Authority, Trust from Shijiazhuang Land Auto Component Ltd.

Shijiazhuang Land Auto Component Ltd. brings over two decades of manufacturing experience for heavy-duty vehicle parts. Their R&D, engineering, and quality assurance teams uphold not only the American Type Welding Series Suspension to strict international standards (ISO, ECE, SAE) but also integrate industry advances from researchers and forums such as the Trailer Body Builders Journal.

This commitment to professionalism and long-term reliability positions the company as a global authority and trusted supplier.

Professional FAQ: Understanding Key Terms and Standards

Why Choose Shijiazhuang Land Auto Component Ltd. for

American Type Welding Series Suspension?

- R&D leadership: Decades of research in welding, metallurgy, and vehicle dynamics.

- Global Certifications: Compliant with ISO, ECE, SAE, and DOT standards.

- Customization: Bespoke suspension design for unique vehicle architectures.

- After-Sales Service: 24/7 technical support, fast component dispatch, and installation guidance.

- Competitive Pricing: Exceptional value per lifecycle mile, thanks to in-house manufacturing and quality controls.

For direct inquiries, please call +86 13091005279 or email info@land-d.cn.

Latest Industry Research & Community Feedback

According to the Trailer Body Builders Journal, welding-based trailer suspensions have seen adoption increase by 18% over the last five years in heavy logistics fleets, primarily for their low total-cost-of-ownership metrics and reliability under high-frequency cycling.

Forum discussions on Heavy Equipment Forums reinforce the growing demand for American-style welded suspension systems due to enhanced ride quality and easier part replacement.

-

American Type Welding Series Suspension - Durable Industrial Solution

NewsJul.26,2025

-

High-Strength Semi Trailer Kingpin Plate Replacement for Secure Transport

NewsJul.25,2025

-

Holland Fifth Wheel Rebuild Kit for Heavy-Duty Trucks – Durable & Reliable

NewsJul.24,2025

-

JOST TAPE Fifth Wheel 37C Repair Kits-Shijiazhuang Land Auto Component Ltd.|Durable Performance&Reliable Solutions

NewsJul.23,2025

-

Holland Fifth Wheel Rebuild Kit – Durable & Easy Replacement Parts

NewsJul.23,2025

-

Premium 5th Wheel Bumper Kit for Safe Towing & Easy Installation

NewsJul.22,2025