jul. . 28, 2025 16:40 Tornar a la llista

How Do 5th Wheel Systems Enhance Commercial Hauling Efficiency and Versatility?

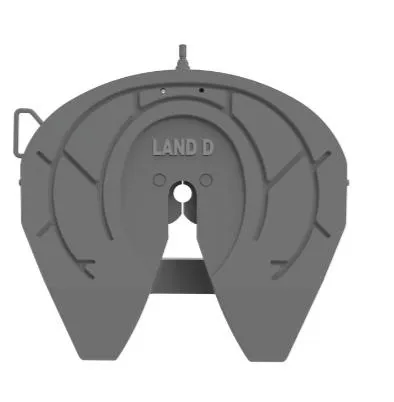

In the realm of heavy - duty transportation, 5th wheel systems serve as a cornerstone for connecting tractors to semi - trailers, enabling safe and efficient freight hauling. The advantages of 5th wheel technology, combined with features like adjustable components and axle flip solutions, have revolutionized commercial trucking by addressing challenges related to load distribution, maneuverability, and maintenance. This exploration delves into how these systems work, their key benefits, and the practical solutions they offer for optimizing hauling operations.

Exploring the Core Benefits of 5th Wheel Technology

One of the primary benefits of a 5th wheel system is its ability to provide a secure and stable connection, a key advantage of 5th wheel that significantly reduces the risk of trailer detachment during transit. The design of a 5th wheel coupling, with its robust locking mechanism, evenly distributes the vertical and horizontal forces exerted by the trailer, enhancing overall vehicle stability. For long - haul trucks navigating diverse terrains, this stability translates to better control, reduced wear on tires and suspension components, and improved fuel efficiency. Additionally, the elevated position of the 5th wheel allows for a tighter turning radius, making it easier to maneuver in confined spaces—an essential feature for urban delivery routes or construction sites.

Understanding the Adjustment Process for Semi - Truck Fifth Wheels

Proper maintenance of a semi - truck’s fifth wheel includes knowing when and how to perform adjustments, such as when addressing issues like excessive play or uneven weight distribution. The adjusting fifth wheel on semi typically involves checking the lock mechanism, lubricating moving parts, and ensuring the correct alignment between the tractor and trailer. For example, if a driver notices trailer sway or unusual noise during turns, adjusting the fifth wheel’s lock tension or replacing worn components can restore optimal performance. Following the manufacturer’s guidelines for adjustment is crucial to avoid damaging the coupling, as incorrect adjustments may compromise safety and lead to costly breakdowns.

Leveraging Adjustable Features for Customized Hauling

Modern commercial vehicles often utilize an adjustable fifth wheel to accommodate different trailer heights and weight distributions, ensuring optimal load balance and maneuverability. These adjustable systems allow operators to fine - tune the position of the fifth wheel along the tractor’s frame, which is particularly useful when hauling trailers with varying deck heights or when redistributing weight to meet axle load limits. By optimizing the fifth wheel’s position, drivers can improve traction, reduce stress on the driveline, and comply with regulatory weight restrictions—all while maintaining the flexibility to switch between different trailers as needed.

Maximizing Utility with Axle Flip Solutions

For fleets requiring enhanced ground clearance or the ability to adapt to unique hauling needs, a Kit de volteig de l'eix de la cinquena roda or 5th wheel axle flip can be a game - changing solution. An axle flip involves reversing the position of the trailer axle relative to the suspension, effectively raising or lowering the trailer deck height. When combined with a compatible 5th wheel system, this modification allows operators to transport taller cargo without exceeding height restrictions or to lower the center of gravity for improved stability when hauling heavy loads. A Kit de volteig de l'eix de la cinquena roda typically includes the necessary hardware to safely perform the conversion, providing a cost - effective way to customize trailers for specific applications.

FAQ: Key Insights into 5th Wheel Systems

What are the main safety benefits of a properly adjusted 5th wheel?

A properly adjusted 5th wheel ensures a secure connection, reducing the risk of trailer separation—a critical safety advantage of 5th wheel. It also minimizes excessive movement between the tractor and trailer, which can cause sway or jackknifing, especially in adverse weather conditions. Regular adjustments help maintain even weight distribution, preventing tire overloading and improving braking efficiency.

How often should I adjust the fifth wheel on my semi - truck?

The frequency of adjustments depends on usage and operating conditions. In general, inspect the fifth wheel during routine maintenance (every 10,000–20,000 miles) or whenever signs of misalignment appear, such as uneven tire wear, trailer instability, or difficulty coupling/uncoupling. Heavy - duty applications or rough terrain may require more frequent checks.

Can an adjustable fifth wheel improve fuel efficiency?

Yes, an adjustable fifth wheel can contribute to better fuel efficiency by optimizing the trailer’s position for reduced air resistance and improved weight distribution. Proper alignment minimizes drag and tire rolling resistance, which are significant factors in fuel consumption during long hauls.

What is the purpose of a 5th wheel axle flip, and when is it necessary?

A 5th wheel axle flip is used to change the trailer’s deck height, either to accommodate taller cargo or to lower the center of gravity for stability. It’s necessary when standard configurations can’t meet load height requirements or when hauling heavy, low - profile loads that benefit from a lower center of mass.

Are there weight restrictions when using a 5th wheel axle flip kit?

Yes, weight restrictions vary based on the trailer’s design and the axle flip kit’s specifications. Always consult the manufacturer’s guidelines to ensure the modified setup complies with legal weight limits and maintains structural integrity. Overloading can compromise safety and lead to regulatory penalties.

-

Why Are Specialized Components Crucial in Commercial Vehicle Maintenance and Operation?

NotíciesJul.28,2025

-

Why Are Fifth Wheels Critical for Trucking and How to Select the Right One?

NotíciesJul.28,2025

-

What Defines the Excellence of American Trailer Components in Key Markets?

NotíciesJul.28,2025

-

What Defines the Excellence of American 5th Wheel Systems and Their Market Offerings?

NotíciesJul.28,2025

-

How Do 5th Wheel Trailers Redefine Towing and Living Standards?

NotíciesJul.28,2025

-

How Do 5th Wheel Systems Enhance Commercial Hauling Efficiency and Versatility?

NotíciesJul.28,2025