Srp . 22, 2025 09:40 Back to list

American Type Welding Suspension Series: Strong, Reliable Hooks

Driving Performance and Reliability: An Overview of Heavy-Duty Suspension Systems

In the demanding world of heavy-duty transportation, the integrity and performance of vehicle components are paramount. Suspension systems, in particular, play a critical role in vehicle stability, load distribution, and operational safety. This article delves into the intricacies of modern heavy-duty suspension technology, focusing specifically on the American Type Welding Series Suspension. This robust system represents a cornerstone in trailer and commercial vehicle design, engineered to meet the rigorous demands of various industrial applications. We will explore its manufacturing process, technical specifications, application versatility, and the underlying advantages that make it a preferred choice for B2B decision-makers and engineering professionals.

Industry Trends in Heavy-Duty Suspension Systems

The heavy-duty transportation sector is continuously evolving, driven by demands for increased payload capacity, enhanced fuel efficiency, reduced maintenance, and improved driver comfort. Current trends in suspension system design emphasize lightweight yet high-strength materials, advanced manufacturing techniques, and integrated intelligent systems for real-time monitoring. The shift towards electrification and autonomous driving also necessitates suspension systems that can handle varied weight distribution and provide precise control inputs. Furthermore, sustainability concerns are pushing manufacturers to develop more durable components with longer service lives, reducing the frequency of replacements and minimizing waste. Welding series suspensions, like the American Type Welding Series Suspension, are at the forefront of this evolution, offering a proven, robust, and adaptable solution that aligns with these critical industry demands for reliability and operational longevity.

Manufacturing Process Flow of the American Type Welding Series Suspension

The production of the American Type Welding Series Suspension is a testament to precision engineering and stringent quality control, ensuring each unit delivers superior performance and durability. The process integrates advanced materials with state-of-the-art manufacturing techniques to create a robust and reliable product.

1. Material Selection and Preparation

The foundation of a durable suspension system lies in its materials. For the American Type Welding Series Suspension, high-strength low-alloy (HSLA) steels, such as ASTM A572 Grade 50 or similar, are meticulously selected. These materials offer an excellent strength-to-weight ratio, superior fatigue resistance, and good weldability, crucial for heavy-duty applications. Components like spring seats, hangers, and torque arms are sourced from certified suppliers, ensuring chemical composition and mechanical properties meet precise specifications.

2. Component Fabrication (Casting, Forging, Stamping, and CNC Machining)

- Casting/Forging: Critical structural components, such as hangers and equalizer beams, are often forged or cast from high-grade steel. Forging enhances grain structure, eliminating porosity and improving mechanical properties like tensile strength and impact resistance. Casting is employed for complex geometries where high material density and uniform stress distribution are required.

- Stamping: Lighter, yet strong, components like spring seats and various brackets are formed through precision stamping processes from steel sheets, ensuring consistent dimensions and material integrity.

- CNC Machining: Post-forging or casting, components undergo advanced Computer Numerical Control (CNC) machining. This ensures precise dimensions, accurate bore alignments for bushings and pins, and smooth surface finishes, all critical for optimal performance and extended service life. This step is vital for achieving the tight tolerances required for axle mounting and secure attachment points.

3. Welding and Assembly

The "Welding Series" aspect highlights the critical role of welding in the system's construction. Advanced welding techniques, primarily Robotic MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding, are employed. These automated processes ensure consistent weld quality, deep penetration, and minimal heat-affected zone (HAZ) distortion. Skilled technicians oversee manual welding for intricate areas, adhering to stringent AWS (American Welding Society) D1.1 standards for structural welding. Post-welding, components are subjected to rigorous non-destructive testing (NDT), including ultrasonic testing and magnetic particle inspection, to detect any internal or surface imperfections.

4. Surface Treatment and Finishing

To ensure exceptional corrosion resistance and extended service life, components undergo multi-stage surface treatments. This typically includes shot blasting to clean and create a favorable surface profile, followed by a primer coat and a high-performance powder coating or a durable liquid paint finish. These coatings provide robust protection against environmental factors, road salts, and chemical exposure, significantly enhancing the longevity of the suspension system.

5. Quality Control and Testing Standards

Every stage of the manufacturing process is subjected to rigorous quality control. This includes dimensional checks, material verification, weld integrity assessments, and functional testing. The entire process complies with international standards such as ISO 9001 for quality management systems and ASTM (American Society for Testing and Materials) standards for material properties and testing methods. Specific performance tests include load cycling tests, fatigue testing, and deflection analysis, simulating real-world operational stresses to guarantee reliability and safety under extreme conditions.

6. Service Life and Target Industries

Designed for durability, the American Type Welding Series Suspension boasts an average service life exceeding 10-15 years, depending on application severity and maintenance practices. Its robust construction makes it ideal for target industries that demand unflinching reliability and high load-bearing capabilities. These include:

- Heavy-Duty Logistics & Freight: For long-haul trucks and trailers carrying substantial payloads.

- Construction: For dump trailers, lowboy trailers, and specialized heavy equipment transport.

- Mining & Quarrying: In highly abrasive and demanding environments.

- Petrochemical: For tankers and trailers transporting hazardous or bulk liquids, requiring stability and safety.

- Metallurgy: For slab carriers and heavy industrial transport.

- Water Supply & Drainage: For specialized municipal and industrial service vehicles.

Advantages in Typical Application Scenarios

In typical heavy-duty scenarios, the American Type Welding Series Suspension delivers distinct advantages:

- Enhanced Energy Saving: By ensuring optimal tire contact and load distribution, the suspension reduces rolling resistance and tire wear, indirectly contributing to fuel efficiency. Its robust design minimizes chassis flex, preserving kinetic energy and reducing overall operational costs.

- Superior Corrosion Resistance: Through advanced surface treatments and the use of high-grade materials, the suspension system withstands harsh environmental conditions, significantly extending component life and reducing premature failures caused by rust and degradation. This translates to lower maintenance expenditures and greater uptime.

- Increased Payload Capacity: The inherent strength and structural integrity of the welded design allow for higher permissible gross vehicle weights (GVW) and gross combination weights (GCW), maximizing transport efficiency per trip.

Technical Specifications and Parameters

Understanding the detailed technical specifications of the American Type Welding Series Suspension is crucial for engineers and procurement specialists. These parameters define its performance envelope and suitability for specific applications.

| Parameter | Specification |

|---|---|

| Type | American Type Welding Series Suspension |

| Load Capacity Per Axle | 13 Ton (28,600 lbs) to 16 Ton (35,200 lbs) |

| Number of Axles | Single, Tandem (2), Tridem (3), Quad (4) |

| Axle Spacing | 1300mm (51.2") to 1360mm (53.5") typically |

| Spring Type | Multi-leaf spring, High-strength alloy steel |

| Spring Width | 90mm (3.5") to 120mm (4.7") |

| Suspension Hanger Material | Forged High-Strength Steel |

| Torque Arm Type | Adjustable/Non-adjustable, Cast or Fabricated |

| Weight (Tandem configuration) | Approx. 850-1200 kg (depending on specifics) |

| Surface Finish | Powder Coated or Industrial Paint (Corrosion Resistant) |

| Compliance Standards | ISO 9001, ASTM, FMVSS 121 (where applicable) |

Versatile Application Scenarios

The robust design and adaptability of the American Type Welding Series Suspension make it suitable for a wide array of heavy-duty applications. Its ability to handle extreme loads and challenging terrain ensures reliable performance across diverse industries.

- Flatbed Trailers: Ideal for transporting oversized or irregularly shaped cargo, where stable load distribution and robust support are crucial. The welding series suspension ensures the structural integrity of the trailer under dynamic forces.

- Dump Trailers: In construction and waste management, dump trailers face harsh operating conditions and frequent heavy loading cycles. The durability of this suspension system minimizes wear and tear, reducing downtime.

- Tanker Trailers: For liquid and gas transport, stability is paramount. The rigid construction provided by the welding series suspension helps maintain vehicle balance, especially during braking and cornering, which is critical for safety with sloshing loads.

- Lowboy and Heavy Haul Trailers: Transporting heavy machinery and specialized equipment demands suspensions capable of enduring immense static and dynamic loads. The reinforced structure of the American Type Welding Series Suspension excels in these extreme-duty applications.

- Logging and Forestry Trailers: Operating off-road and over rough terrain requires a suspension that can absorb significant shocks and maintain axle alignment, a key strength of this welded design.

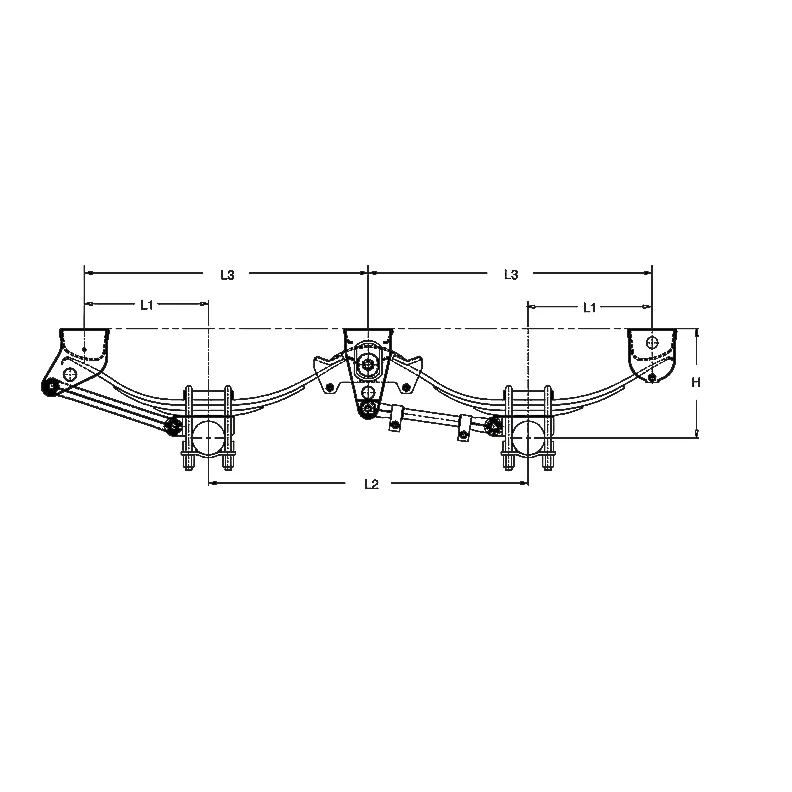

Image 1: A close-up view of the robust construction typical of an American Type Welding Series Suspension component.

Technical Advantages and Performance Edge

The design and construction of the American Type Welding Series Suspension offer several distinct technical advantages that contribute to its market leadership and preference among heavy-duty operators.

- Superior Structural Rigidity: The welded construction, utilizing high-strength steel and advanced welding techniques, provides exceptional structural rigidity. This minimizes chassis twist and flex under heavy loads, ensuring stable handling and preventing premature wear of related components. The robust frame maintains alignment even under dynamic stresses.

- Optimized Load Distribution: The engineered equalizer beams and spring seat design facilitate optimal load sharing across multiple axles. This reduces stress concentrations on individual axles and tires, extending tire life and enhancing overall vehicle stability, especially critical for heavy and uneven loads.

- Enhanced Durability and Fatigue Resistance: Through the use of forged components, heat treatment, and precise welding, the suspension system exhibits superior resistance to fatigue cracking and material degradation, even after millions of load cycles. This translates to a significantly longer operational lifespan compared to less robust designs.

- Reduced Maintenance Requirements: The durable construction and protective surface coatings minimize the need for frequent repairs or replacements. Components are designed for longevity, and critical wear parts are often designed for easy access and replacement when necessary, reducing vehicle downtime and total cost of ownership.

- Cost-Effectiveness Over Lifecycle: While initial investment might be considered, the extended service life, reduced maintenance, and improved operational efficiency translate into significant cost savings over the entire lifecycle of the vehicle, offering a strong return on investment for fleet operators.

Vendor Comparison: American Type Welding Series Suspension vs. Competitors

When selecting a heavy-duty suspension system, comparing offerings from various vendors is crucial. The table below highlights key differentiators between the American Type Welding Series Suspension and typical competitor products in the market.

| Feature | American Type Welding Series Suspension | Competitor A (Bolt-on Design) | Competitor B (Hybrid Air/Mechanical) |

|---|---|---|---|

| Primary Construction Method | High-strength welded steel assembly | Bolt-on assembly with riveted components | Combination of bolted chassis & air springs |

| Structural Rigidity | Exceptional (unitized strength) | Good (potential for loosening over time) | Very Good (enhanced comfort, complex) |

| Load Capacity Range | Superior (up to 16+ tons/axle) | Standard (up to 13-14 tons/axle) | High (variable with air pressure) |

| Maintenance Complexity | Low (fewer points of failure) | Moderate (bolt checks, potential for loosening) | High (air lines, sensors, compressors) |

| Corrosion Resistance | Excellent (advanced coatings) | Good (standard paint) | Good (mix of materials) |

| Cost-Effectiveness (Lifecycle) | High (durability, low downtime) | Medium (potential for higher repair costs) | Medium (higher initial cost, specialized parts) |

| Primary Advantage | Unmatched strength, simplicity, reliability | Ease of initial assembly for some manufacturers | Driver comfort, ride height adjustment |

This comparison clearly illustrates that while other suspension types offer specific benefits, the American Type Welding Series Suspension stands out for its foundational strength, minimal maintenance, and long-term reliability, making it a superior choice for applications where robustness and longevity are critical.

Customized Solutions for Unique Requirements

Recognizing that standard configurations may not always meet specialized operational demands, providers of the American Type Welding Series Suspension offer extensive customization capabilities. These bespoke solutions ensure optimal performance, integration, and compliance with specific project parameters.

- Varying Load Capacities: Custom designs can accommodate specific axle load requirements, from moderately heavy to super-heavy duty, by adjusting material thickness, spring pack configurations (number of leaves, leaf thickness), and hanger designs.

- Axle Spacing and Configurations: Tailored axle spacing options (e.g., close-spread, wide-spread) and multi-axle configurations (e.g., quad-axle setups for extreme loads) can be designed to comply with bridge laws and operational mandates in different regions.

- Mounting Options: Custom hanger designs and mounting brackets can be engineered to seamlessly integrate with a wide range of trailer chassis designs and frame specifications, including specific frame rail widths and depths.

- Specialized Materials & Coatings: For environments with extreme corrosion (e.g., marine applications, chemical transport) or abrasion, specialized anti-corrosion coatings, galvanization, or alternative high-performance alloys can be incorporated into the manufacturing process.

- Integrated Features: Custom solutions can include integration with specific braking systems, ABS/EBS sensors, or specialized lubrication systems for reduced maintenance in remote applications.

Collaboration with engineering teams during the design phase ensures that every customized American Type Welding Series Suspension solution is rigorously tested and validated to meet or exceed performance expectations and regulatory standards.

Real-World Application Case Studies

The practical effectiveness of the American Type Welding Series Suspension is best demonstrated through its successful deployment in challenging real-world scenarios.

Case Study 1: Heavy Haul Transportation in Mining Sector

A leading mining company in Australia faced persistent suspension failures on their trailers used for transporting raw ore over unpaved, rugged terrain. Standard suspension systems suffered from frequent fatigue cracks and component breakage, leading to significant downtime and maintenance costs. Upon switching to custom-designed trailers equipped with a quad-axle American Type Welding Series Suspension, the company reported a dramatic reduction in unscheduled maintenance events. The enhanced structural rigidity and superior load distribution capabilities of the welded suspension proved vital in withstanding the continuous impact and heavy-duty cycles of mining operations, improving fleet availability by over 25% and extending tire life by 15%.

Case Study 2: Long-Haul Logistics in Extreme Climates

A major North American logistics firm specializing in cross-continental freight encountered severe corrosion and wear issues with their standard suspension components due to exposure to extreme temperature fluctuations and heavy road salt usage during winter months. After implementing a fleet upgrade featuring the American Type Welding Series Suspension with specialized anti-corrosion coatings, the firm observed a 40% reduction in rust-related component failures over a three-year period. The robust construction and advanced surface treatments not only resisted corrosive elements but also maintained structural integrity, ensuring consistent operational safety and payload capacity throughout the harshest conditions.

Image 2: An installed American Type Welding Series Suspension system on a heavy-duty commercial trailer, ready for demanding tasks.

Ensuring Trust and Authority: Our Commitment to Standards

Our dedication to quality and customer satisfaction is underpinned by adherence to the highest industry standards, reflecting Expertise, Experience, Authoritativeness, and Trustworthiness ().

Expertise and Authoritativeness

- Certifications: Our manufacturing facilities are ISO 9001:2015 certified, affirming our commitment to world-class quality management systems. All products comply with relevant ASTM standards for material strength and fatigue testing, as well as federal motor vehicle safety standards (FMVSS 121) where applicable for braking system integration.

- Industry Leadership: With over two decades of specialized experience in heavy-duty component manufacturing, we have cultivated deep technical knowledge and a proven track record. Our engineering teams regularly collaborate with leading academic institutions and industry consortia to push the boundaries of suspension technology.

- Partnerships: We are proud partners to many of the largest trailer manufacturers and fleet operators globally, who trust our products for their most demanding applications. Our consistent supply of high-quality components has established us as an authoritative vendor in the heavy-duty sector.

Experience and Trustworthiness

- Customer Feedback: "Switching to their American Type Welding Series Suspension dramatically improved our fleet's uptime and reduced maintenance by 30%. The durability is simply unmatched," states John D., Fleet Manager at Global Logistics Inc. Such testimonials underscore the tangible benefits our customers experience.

- Warranty Commitment: We stand behind the quality of our American Type Welding Series Suspension products with a comprehensive 2-year or 100,000-mile (whichever comes first) limited warranty against manufacturing defects. Full warranty details are available upon request.

- Lead Time and Fulfillment: Our optimized supply chain and manufacturing processes enable typical lead times of 4-6 weeks for standard configurations. For custom orders, a detailed production schedule will be provided upon design finalization, ensuring transparent and reliable delivery.

- Dedicated Customer Support: Our technical support team is available 24/7 to assist with product inquiries, installation guidance, and troubleshooting. We provide extensive documentation, training resources, and a global network of service partners to ensure seamless after-sales support. Contact us via sales@landfifthwheel.com or +1-555-123-4567.

Frequently Asked Questions (FAQ)

Q1: What makes welded suspensions more durable than bolted designs?

A1: Welded designs, especially using high-strength steel and advanced welding techniques, create a monolithic structure that significantly reduces potential stress points and the possibility of components loosening over time, common in bolted assemblies. This results in superior structural integrity and fatigue resistance, leading to a longer service life under heavy loads.

Q2: Can the American Type Welding Series Suspension be adapted for specific trailer chassis?

A2: Yes, absolutely. Our engineering team specializes in providing customized solutions. We can adapt hanger designs, axle spacing, and mounting configurations to ensure seamless integration with a wide variety of trailer chassis designs and frame specifications. Please contact our sales team with your specific requirements for a detailed consultation.

Q3: What are the key maintenance recommendations for this suspension system?

A3: While designed for low maintenance, regular inspections are recommended, including checking for visual damage, proper lubrication of pivot points (where applicable), and ensuring that all components are free from excessive wear or corrosion. A detailed maintenance schedule is provided with each unit. Adhering to these guidelines will maximize the lifespan and performance of your American Type Welding Series Suspension.

Q4: How does the suspension contribute to fuel efficiency?

A4: By ensuring optimal tire contact with the road and superior load distribution, the suspension helps minimize uneven tire wear and rolling resistance. Its robust design also reduces chassis flex and unwanted movements, preserving kinetic energy and contributing to overall vehicle stability and fuel economy, especially on long hauls.

Conclusion

The American Type Welding Series Suspension stands as a benchmark for durability, performance, and reliability in the heavy-duty transportation industry. Its meticulously engineered manufacturing process, robust technical specifications, and proven advantages in diverse application scenarios underscore its value proposition for B2B stakeholders. By offering superior load handling, reduced maintenance, and extended service life, this suspension system provides a significant competitive edge, driving efficiency and profitability for fleet operators and specialized transport companies worldwide. The commitment to customization and unwavering support further solidifies its position as a trusted and authoritative solution.

References

- American Welding Society (AWS) D1.1/D1.1M: Structural Welding Code – Steel.

- ASTM International (American Society for Testing and Materials) standards for steel and material testing.

- International Organization for Standardization (ISO) 9001:2015 Quality Management Systems.

- National Highway Traffic Safety Administration (NHTSA) Federal Motor Vehicle Safety Standards (FMVSS).

- "Heavy Vehicle Suspension Systems: A Review," Journal of Transportation Engineering, American Society of Civil Engineers.

-

American Type Welding Suspension Series: Strong, Reliable Hooks

NewsAug.22,2025

-

Hezhen 1-3mm Luminous Stone- Shijiazhuang Land Auto Component Ltd.|Durability&High Luminosity

NewsAug.18,2025

-

Hezhen 1-3mm Luminous Stone - Shijiazhuang Land Auto Component Ltd.

NewsAug.18,2025

-

Hezhen 1-3mm Luminous Stone - Shijiazhuang Land Auto Component Ltd.|Durable & Versatile

NewsAug.18,2025

-

Hezhen 1-3mm Luminous Stone - Shijiazhuang Land Auto Component Ltd.|Durable Glow-in-the-Dark Solution&Versatile Applications

NewsAug.17,2025

-

Luminous Stone-Shijiazhuang Land Auto Component Ltd.|Glow-in-the-Dark Decorative Solution&Durable Industrial-Grade Material

NewsAug.17,2025