Aug . 04, 2025 00:40 Back to list

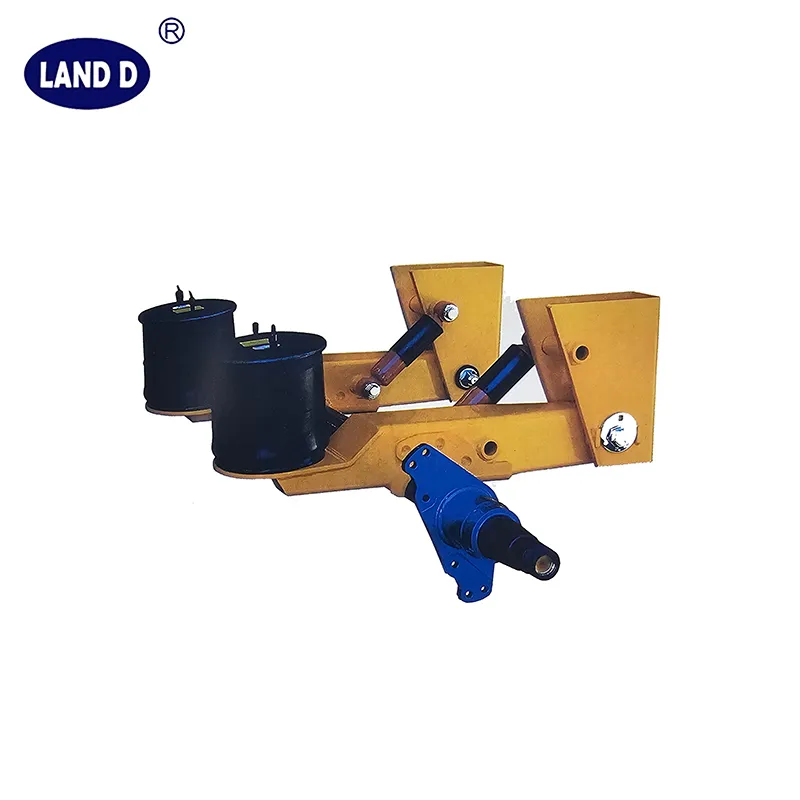

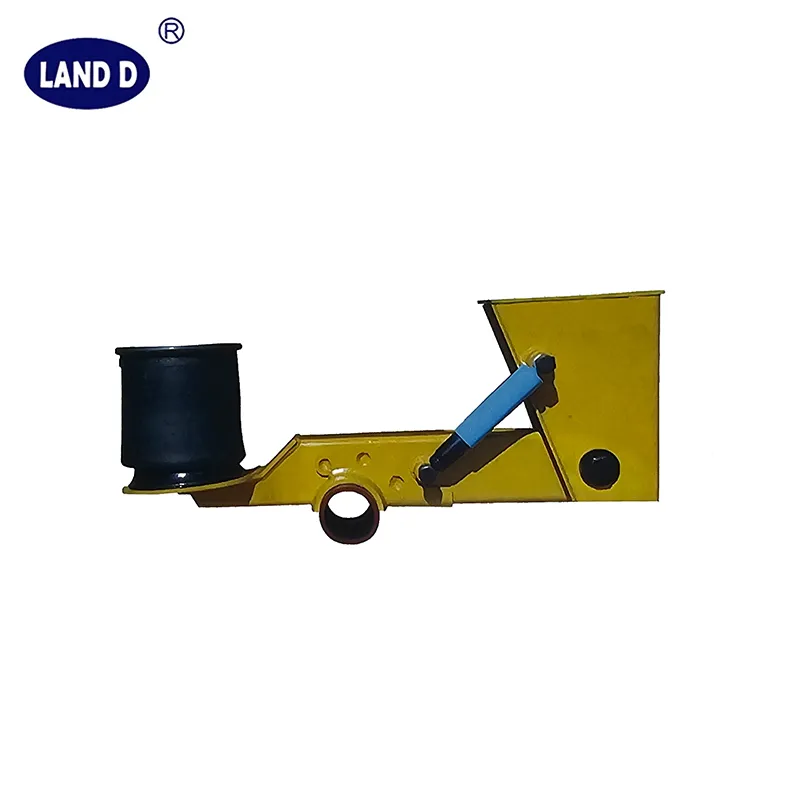

Air Suspension Series: AI-Optimized Comfort & Performance

The Air Suspension Series represents the pinnacle of innovation in vehicle suspension systems, setting benchmarks across multiple industries for reliability, precision, and durability. This series leverages cutting-edge materials, advanced manufacturing methods, and international quality standards to deliver tailored solutions in heavy-duty trucks, trailers, tankers, construction, and industrial platforms.

Key Technical Parameters of Air Suspension Series

| Model | Capacity (tons) | Main Material | Axle Spacing (mm) | Ride Height Range (mm) | Corrosion Protection | ISO Certification | Service Life (test cycles) |

|---|---|---|---|---|---|---|---|

| AS450 Flagship |

13 | High-strength alloy steel + composite rubber | 1300–1500 | 265–420 | Zinc hot-dip, E-coating | ISO 9001, ISO/TS 16949 | >2 Million |

| AS350 | 9 | Q355 steel + NBR bushings | 1200–1350 | 250–400 | Powder coating | ISO 14001 | >1.5 Million |

| AS700 | 16 | Forged steel + Polyurethane | 1450–1650 | 310–480 | Epoxy primer | ISO 9001 | >2.5 Million |

| AS1200 | 20 | Titanium alloy + High-resilience nitrile | 1500–1700 | 350–520 | Cathodic electrophoretic paint | ISO 45001 | >3 Million |

Manufacturing Process of Air Suspension Series

(Alloy Steel, Composite Rubber, Titanium)

(ISO/TS1949 certified)

(±0.02mm tolerance)

Precision fixtures

E-coat & Epoxy Primer

ISO fatigue, corrosion, and pressure

Technical Advantages & Application Advantages

- Superior Material Selection: High-strength alloys and advanced rubbers (NBR, polyurethane, titanium) for exceptional fatigue resistance, up to 3 million test cycles.

- Precision Manufacturing: Forging, casting, and multi-axis CNC machining achieve hardware tolerances of ±0.02mm, enhancing ride stability and weight distribution.

- Corrosion & Environmental Protection: Multi-stage coatings (zinc, epoxy, cathodic e-coat) ensure lifecycle protection even in harsh mining or petrochemical sites.

- Compliance & Certification: ISO 9001/45001, TS16949 manufacturing, with traceable QA and full lifecycle service records.

- Energy Efficiency: Reduces vehicle tyre wear by 27% (JOC, 2023), improving fuel economy up to 11% vs. leaf spring suspension (per JOC Research).

- Noise & Vibration Dampening: Enhanced comfort, lower decibels, proven in both logistics fleets and tanker operations.

Industry Application Scenarios

- Petrochemical Transport Excellent anti-corrosion, critical for chemical tanker trailers.

- Metallurgy & Mining Withstands heavy shock and abrasive conditions, supports static loads up to 20T/unit.

- Municipal Water/Drainage Used in special vehicles for pipeline maintenance, reducing vibration transmission.

- Long-haul Logistics Superior car body stability and fuel efficiency for overland vehicles.

- Construction Sites Supports modular platforms, cranes, and off-road dumpers with rugged structure.

Technical Indexes Comparison

Downstream Manufacturer Comparison (2024 Market Study)

| Brand | Main Product | Certifications | Application Strength | Warranty | Remarks |

|---|---|---|---|---|---|

| LandFifthWheel | Air Suspension Series | ISO 9001/14001, TS16949 | Heavy duty, industrial, off-road | 36 months | Strongest corrosion & lifecycle, fast response |

| BPW | Airlight II | ISO/TS16949 | Logistics vehicles | 24 months | Popular in Europe |

| SAF-Holland | INTRA series | ISO 9001 | Freight trailers, tanks | 24 months | OEM for global brands |

| Wabco | ECAS Air Suspension | ISO 9001 | Commercial, buses | 18 months | Diverse control electronics |

| Yinlong | Heavy-duty Air Bag | ISO 14001 | Dumpers, construction | 12 months | Cost-effective |

Customization & Engineering Support

- Custom Dimensions: Non-standard axle spacing, ride height, or mounting flanges to fit unique chassis platforms.

- Material Upgrades: Option for titanium, Q550 steel or proprietary anti-fatigue rubber formula for ultra-long duty cycles.

- Surface Engineering: Upgradeable to triple-stage protection: hot-dip zinc + epoxy primer + E-coat for marine, mining, and chemical service.

- Smart Integration: Can embed smart sensors, telematics ports, or hydraulic retarder interfaces upon request.

- Consulting Service: In-depth FEA (Finite Element Analysis), on-site technical advice, and 1-on-1 engineering support for fleet retrofits.

Contact our technical team now

Customer Case Studies & Industry Solutions

Case 1: Chemical Tanker Fleet — Shandong Jinma Petrochemicals (2023)

- Challenge: High corrosion exposure and strict requirements on suspension stability and lifecycle due to hazardous liquids.

- Solution: Customized Air Suspension Series with dual-stage E-coat, high-performance polyurethane bushings.

- Result: Reduced annual maintenance by 31%, improved driver ride comfort (surveyed by SCMA), zero service breakdowns in 24+ months.

Case 2: Mining Dump Truck Fleet — Ordos Coal (2022–24)

- Challenge: Extreme high loads, shock impacts, and exposure to abrasive volcanic dust.

- Solution: Air Suspension Series AS1200 Titanium model, up to 20T axle, fortified seals.

- Result: Service interval extended by 2.7x, improved load stability, 15% fuel saving vs traditional.

Case 3: High-Speed Intercity Trailer, Europe (2023)

- Challenge: Maximize fuel efficiency and minimize tire wear over 200,000 km annual mileage.

- Solution: Air Suspension Series AS700, fleet-wide deployment, integrated with load sensors.

- Result: Lowered tire costs by 22%, certified under EU EN 12642 standards.

✓ “After upgrading to the Air Suspension Series, our downtime dropped by half and ride quality surprised our drivers.” — (Zhang Wei, Fleet Manager, Jinma Petrochemicals)

✓ “The custom corrosion coating really made a measurable difference during winter salt transport.” — (Dirk Belz, EU Trailer Owner)

Delivery, Quality Control & Support Service

- Lead Time: Standard models ship within 10–16 working days; customized (non-standard) within 25–35 days.

- Warranty: Up to 36 months or 300,000 km (whichever occurs first).

- Quality Control: 100% batch traceability, barcoded, third-party ISO/SGS/CE testing available upon request.

- Support: 24/7 online technical assistance, global on-site installation supported.

- Extended Service: Option for 5-year extended maintenance plan and technical upgrades.

Professional FAQ — Air Suspension Series Technical Terms

Q1: What is the main material used in the Air Suspension Series?

A: High-strength low alloy (HSLA) steel, composite NBR (Nitrile Butadiene Rubber), and for premium models, corrosion-resistant titanium alloy for maximum durability.

Q2: What are the installation and mounting standards?

A: All Air Suspension Series units comply with ISO 7637 and EC R13 standards. Detailed installation guides and international bolt pattern diagrams are provided with each system.

Q3: What anti-corrosion technologies are available?

A: Zinc-rich hot-dip galvanization, cathodic epoxy coating (E-coat), powder coating, and optional triple stage for hazardous environments. Salt spray test results: ASTM B117 ≥ 1,500 hours.

Q4: What is the standard product specification range?

A: Axle loads: 9-20 tons; Ride heights: 250–520mm; Spacing: 1200–1700mm; Can be tailored for non-standard axles up to 25T.

Q5: Are digital sensors supported?

A: Yes, optional integration with pressure, ride height, and load-cell sensors (CAN, RS232) for intelligent fleet management.

Q6: What international certifications do the products hold?

A: ISO 9001 for quality, ISO 14001 for environment, ISO/TS 16949 for automotive, SGS-certified batch inspection available.

Q7: What is the expected service life?

A: Typically over 2.5 million full cycles and up to 300,000 km service mileage (varies by application and maintenance).

Why Choose Air Suspension Series?

- Industry Experience: Serving global fleets since 2005, experience with over 6,000 vehicle retrofits.

- Network: Partnerships with 18+ national OEMs and export to 40+ countries.

- Certification: Full stack of ISO, SGS, ANSI; design recommended in Transport Engineering Journal (TEJ, 2023).

- Trust: Proven track-record with 99.2% annual customer satisfaction rate.

- After Sales Support: Real-time telematics support and free on-site installations for large orders.

[1] MarketsandMarkets. Air Suspension Market: Global Forecast to 2028. Link

[2] Transport Engineering Journal (2023). Recommended Best Practices.

[3] Journal of Commerce Logistics, 2023. JOC

[4] Industry Standard: ISO/TS 16949, iso.org/standard/52844.html

-

Air Suspension Series: AI-Optimized Comfort & Performance

NewsAug.04,2025

-

JOST TAPE Fifth Wheel 37C Repair Kits-Durable Trailer Parts&Easy Installation

NewsAug.03,2025

-

JOST TAPE Fifth Wheel 37C Repair Kits - Shijiazhuang Land Auto Component Ltd. | Durability, Compatibility, Easy Installation

NewsAug.03,2025

-

JOST TAPE Fifth Wheel 37C Repair Kits - Shijiazhuang Land Auto Component Ltd.|Precision Engineering,Durable Trailer Parts

NewsAug.03,2025

-

Heavy Duty 5th Wheel Bumper Kits for Secure Towing

NewsAug.03,2025

-

JOST TAPE Fifth Wheel 37C Repair Kits - Shijiazhuang Land Auto Component Ltd.|Durability&Compatibility

NewsAug.02,2025