Aug . 23, 2025 00:20 Back to list

Durable Germany Type Suspension for Heavy Duty Trucks & Trailers

Industry Trends and Market Dynamics in Heavy-Duty Suspension Systems

The global heavy-duty transportation and logistics sector is undergoing significant transformation, driven by increased demand for efficiency, safety, and durability. Industries such as mining, construction, petrochemicals, and specialized logistics depend heavily on robust vehicle performance under extreme conditions. This reliance places immense pressure on critical components like suspension systems, which must not only bear substantial loads but also ensure vehicle stability, operator comfort, and cargo integrity over long distances and varied terrains. Innovations in materials science, manufacturing precision, and intelligent design are paramount for maintaining competitive advantage and meeting evolving regulatory standards.

In this demanding environment, the Germany Type Suspension stands out as a benchmark for engineering excellence. Known for its robust construction, superior load-bearing capacity, and exceptional operational longevity, it addresses the core challenges faced by heavy-duty fleet operators today. The market trend indicates a clear shift towards solutions that promise reduced downtime, lower maintenance costs, and enhanced operational safety, all while accommodating increasingly heavier and more specialized payloads. Furthermore, environmental considerations are driving demand for designs that contribute to better fuel efficiency through optimized weight distribution and reduced rolling resistance.

Understanding Germany Type Suspension: Core Technology and Design Principles

The core technology behind the Germany Type Suspension system is rooted in a commitment to over-engineering for durability and performance. Characterized by its sturdy construction and multi-leaf spring configuration, this system is designed to manage high static and dynamic loads inherent in heavy-duty applications. Key design principles include:

- Multi-Leaf Spring Configuration: Utilizing multiple layers of high-strength spring steel, these systems distribute load stresses effectively, preventing premature fatigue and ensuring a predictable, progressive spring rate under varying load conditions. This design provides superior resistance to sagging and offers excellent shock absorption.

- Robust Hanger and Equalizer Assemblies: Critical connection points, such as hangers and equalizer beams, are typically manufactured from high-grade cast or forged steel. These components are designed with generous cross-sections and reinforced mounting points to withstand extreme torsional forces and shear stresses, ensuring the structural integrity of the entire suspension unit.

- Optimized Axle Alignment: Precision engineering ensures optimal axle alignment, which is crucial for tire longevity, fuel efficiency, and directional stability. The design often incorporates features that facilitate accurate alignment during installation and maintenance, minimizing uneven tire wear and reducing operational costs.

- Enhanced Bushing and Pin Design: High-performance bushings, often made from specialized polymers or metals, are used at pivot points to minimize friction, reduce wear, and extend service intervals. Pins are typically hardened and precision-ground to ensure tight tolerances and secure articulation.

These design elements collectively contribute to a suspension system that is not only capable of handling formidable loads but also excels in providing stability and control, even in the most challenging operational environments. The robust design philosophy translates directly into longer operational life and reduced total cost of ownership for fleet operators.

Manufacturing Process and Quality Assurance

The production of a Germany Type Suspension system adheres to stringent quality control and precision engineering practices, ensuring each component meets the highest industrial standards. The process is a testament to the pursuit of durability and reliability.

1. Materials Selection

The foundation of a durable suspension system lies in its materials. High-grade alloy steels, specifically optimized for fatigue resistance and tensile strength, are selected. For example, spring leaves are typically crafted from specialized spring steels (e.g., SAE 5160, 60Si2Mn), while hangers and equalizers utilize high-strength cast iron (e.g., ASTM A536 ductile iron) or forged steel (e.g., AISI 1045) to resist deformation and fracture under extreme loads. All materials undergo strict chemical composition analysis and mechanical property testing to comply with international standards like ISO 683 and ASTM A36.

2. Precision Engineering & Fabrication

Key components like spring leaves are fabricated through hot rolling, forming, and heat treatment processes. This includes quenching and tempering to achieve the desired hardness and toughness. Critical components such as hangers and equalizers are often produced via forging or precision casting to ensure optimal grain structure and structural integrity, eliminating weak points often associated with less robust manufacturing methods. Shot peening is applied to spring leaves to introduce compressive residual stresses, significantly enhancing fatigue life and corrosion resistance.

3. Advanced Machining and Assembly

Post-fabrication, components undergo advanced CNC machining to achieve tight dimensional tolerances, critical for precise fitment and optimal performance. This ensures that bore sizes for pins and bushings are exact, minimizing play and extending component life. Automated welding processes (e.g., MIG, MAG) are used for structural assemblies, ensuring strong, consistent, and defect-free welds. Surface treatments, such as cathodic electrocoating (e-coating) or high-durability powder coating, are applied to provide superior corrosion resistance, crucial for components exposed to harsh environmental conditions, thereby contributing to an extended service life.

4. Rigorous Testing and Certification

Every stage of the manufacturing process is subjected to rigorous quality control. This includes non-destructive testing (NDT) such as magnetic particle inspection (MPI) and ultrasonic testing (UT) for critical forged or cast components. Finished assemblies undergo comprehensive load testing, fatigue testing (simulating millions of cycles under full load), and dimensional inspection. Our products meet or exceed international testing standards, including ISO 9001 for quality management, DIN standards for specific component dimensions and material properties, and ANSI standards where applicable. This commitment to testing ensures a projected service life that far surpasses industry averages, typically ranging from 500,000 to over 1,000,000 kilometers under normal operating conditions.

Technical Specifications and Performance Parameters

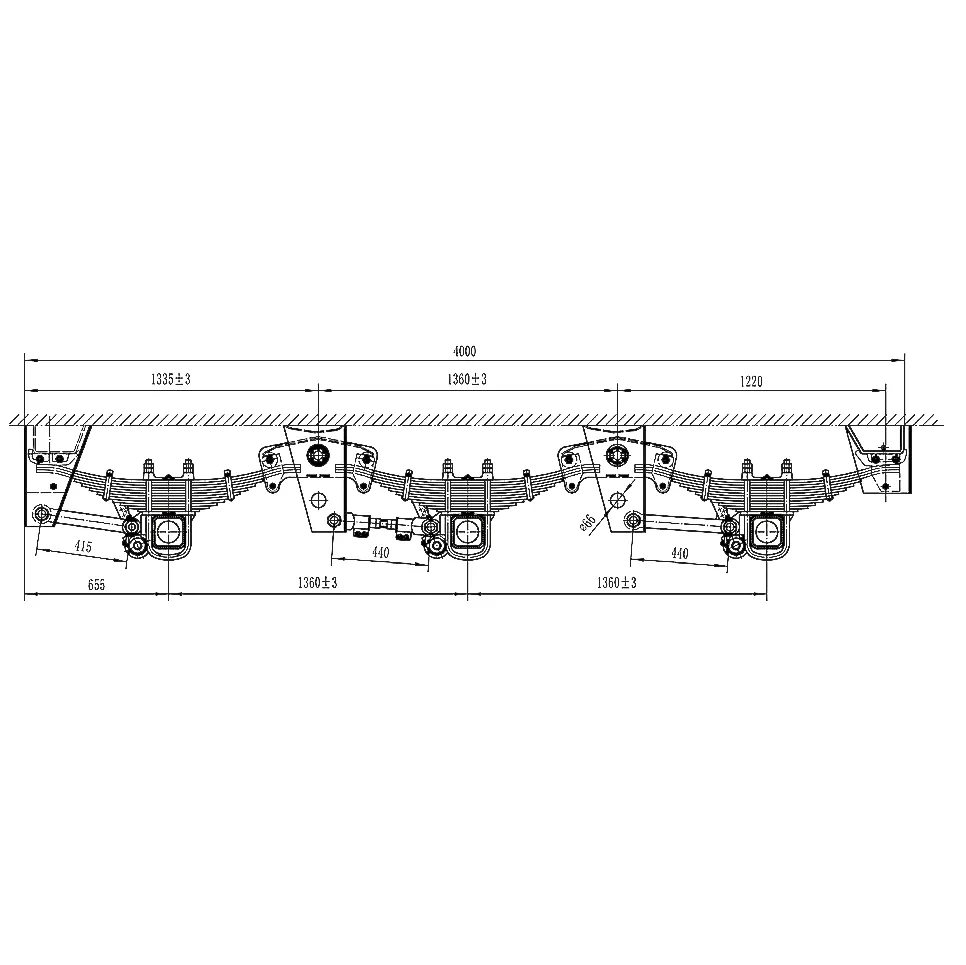

The performance of a Germany Type Suspension system is defined by a precise set of technical specifications designed for optimal heavy-duty operations. These parameters ensure compatibility, safety, and peak operational efficiency across various trailer configurations and load requirements.

| Parameter | Specification (Typical Range) | Unit |

|---|---|---|

| Rated Load Capacity per Axle | 12,000 - 16,000 | kg |

| Number of Axles | 2, 3, 4 (tandem, tri-axle, quad-axle configurations) | - |

| Leaf Spring Width | 90 - 120 | mm |

| Leaf Spring Thickness | 12 - 25 | mm |

| Axle Spacing (Standard) | 1310, 1360, 1550 | mm |

| Mounting Height | Adjustable, typically 130-180 (center of axle to top of chassis) | mm |

| Material Grade (Springs) | 60Si2Mn, SAE 5160, 50CrV4 (Heat-treated alloy steel) | - |

| Material Grade (Hangers/Equalizers) | Ductile Iron (ASTM A536 Gr. 65-45-12) or Forged Steel (AISI 1045) | - |

| Surface Treatment | Shot Peening (springs), E-coating/Powder Coating (components) | - |

| Compliance Standards | ISO 9001, DIN 74012, ECE R55 | - |

These specifications are crucial for engineers and procurement managers to ensure that the suspension system integrates seamlessly with their existing trailer designs and meets the operational demands of their specific industries. Our adherence to these rigorous parameters underlines our commitment to delivering superior performance and long-term reliability.

Application Scenarios Across Key Industries

The versatility and robustness of the Germany Type Suspension make it an indispensable component across a broad spectrum of heavy-duty industries where reliability and load capacity are non-negotiable. Its design ensures superior performance in demanding environments, offering significant advantages such as enhanced energy saving and exceptional corrosion resistance.

- Petrochemical Industry: For the transport of highly volatile or corrosive chemicals in tanker trailers, the stability and robust nature of this suspension system are critical. It mitigates the risk of load shifts, ensuring safe transit even over uneven terrain. The inherent corrosion resistance of treated components extends the operational life in environments prone to chemical exposure and aggressive atmospheric conditions, reducing maintenance frequency and enhancing safety protocols.

- Metallurgy and Mining: In these sectors, trailers often carry extremely heavy, concentrated loads like ores, slag, or large machinery. The high load capacity and durable construction of the Germany Type Suspension are paramount for enduring continuous, high-stress operations. Its ability to absorb shocks from rough terrain and heavy impacts contributes to vehicle longevity and minimizes structural fatigue, leading to significant energy saving by preventing unnecessary chassis stress and improving tire wear.

- Water Supply & Drainage Infrastructure: Transporting large diameter pipes, specialized excavation equipment, or water treatment components often involves navigating challenging urban and rural landscapes. The stability provided by these suspension systems is crucial for preventing damage to sensitive equipment and maintaining balance during transport. The robust design and corrosion resistance ensure reliability even in humid or chemically treated water environments.

- Construction and Heavy Equipment Transport: From transporting pre-fabricated concrete sections to large bulldozers and cranes, trailers equipped with Germany Type Suspension systems offer unparalleled reliability. Their ability to evenly distribute immense loads prevents chassis twisting and allows for safe passage on construction sites or over temporary roads, safeguarding both the cargo and the vehicle.

- General Heavy-Duty Logistics: For oversized or overweight cargo that requires specialized trailers, the predictable performance and strength of these suspension systems are invaluable. They provide the necessary foundation for tailored transport solutions, ensuring compliance with strict weight distribution and safety regulations.

In each of these scenarios, the technical advantages of the Germany Type Suspension translate into tangible operational benefits, including enhanced safety, reduced operational costs, and extended equipment lifespan, making it a preferred choice for demanding B2B applications.

Key Technical Advantages

The design and manufacturing superiority of the Germany Type Suspension translate into several distinct technical advantages that are critical for B2B operations:

- Exceptional Durability and Extended Service Life: Built with high-strength alloy steels and precision engineering, these suspension systems are designed to withstand continuous heavy loads and challenging road conditions. The robust multi-leaf spring configuration, combined with fatigue-resistant components and superior heat treatments, significantly extends the operational lifespan, often exceeding 1,000,000 kilometers under regular maintenance, far surpassing conventional alternatives. This directly translates to lower lifecycle costs and higher asset utilization.

- Superior Corrosion Resistance: Critical components undergo advanced surface treatments, including shot peening for spring leaves and high-performance e-coating or powder coating for hangers and equalizers. These treatments create a highly durable barrier against rust, chemical agents, and environmental degradation, making the system ideal for use in harsh climates, corrosive industrial environments (e.g., coastal regions, chemical transport), and areas with extensive road salting. This resistance maintains structural integrity and appearance over time, reducing the need for costly repairs.

- Enhanced Energy Efficiency: The precise engineering and optimized load distribution characteristics of the Germany Type Suspension contribute to better tire contact and reduced rolling resistance. A well-designed suspension system minimizes chassis flex and ensures consistent tire footprint, which in turn leads to less friction and drag. This subtle but significant improvement can result in tangible energy saving through reduced fuel consumption over the operational life of the trailer, a critical factor for fleet profitability and environmental compliance.

- Unmatched Stability and Safety: The inherent rigidity and controlled damping provided by the multi-leaf spring system deliver superior directional stability and anti-roll characteristics, especially when transporting high-center-of-gravity loads. This significantly enhances safety, reduces the risk of rollovers, and improves handling during dynamic maneuvers. The robust design minimizes component deflection, ensuring consistent brake performance and overall vehicle control under all load conditions, protecting both cargo and personnel.

- Reduced Maintenance Requirements: Through the use of durable materials, precision manufacturing, and effective protective coatings, the maintenance intervals for these suspension systems are significantly extended. Components like high-performance bushings and hardened pins require less frequent inspection and replacement compared to lesser-grade systems, leading to lower operational expenditures and increased vehicle uptime.

Vendor Comparison and Selection Criteria

Choosing the right vendor for Germany Type Suspension systems involves evaluating several critical factors beyond just initial cost. B2B decision-makers must consider product quality, customization capabilities, technical support, and long-term reliability. Below is a comparative overview highlighting key differentiators:

| Feature/Criterion | Leading German Manufacturer | Specialized B2B Supplier (Our Offering) | Cost-Focused Alternative |

|---|---|---|---|

| Product Quality & Materials | Premium alloy steels, highly consistent quality, often proprietary materials. | High-grade alloy steels (60Si2Mn, ASTM A536), ISO-certified, superior finish. | Standard materials, variable consistency, potential for early wear. |

| Manufacturing Precision | World-class precision, advanced robotics, strict DIN standards. | CNC machining, robotic welding, shot peening, adherence to international standards. | Manual assembly, broader tolerances, inconsistent finish. |

| Customization Options | Extensive engineering capabilities, but often with long lead times and high cost. | Flexible design adjustments, tailored load capacities, specific axle configurations, responsive engineering support. | Limited to standard offerings, little to no customization available. |

| Certifications & Compliance | Multiple international certifications (TÜV, DIN, ECE). | ISO 9001, ECE R55, relevant regional certifications, proven test data. | Basic certifications, often lacking comprehensive test reports. |

| After-Sales Support & Warranty | Comprehensive global network, premium support, extensive warranty. | Dedicated technical support, readily available spare parts, competitive warranty terms. | Limited support, slow spare parts availability, minimal warranty. |

| Value Proposition | Highest quality, premium price, long-term brand prestige. | Optimal balance of high quality, customization, support, and competitive pricing for B2B. | Lowest initial cost, but higher total cost of ownership due to premature wear and maintenance. |

Our commitment is to deliver the superior engineering and reliability associated with the Germany Type Suspension, balanced with flexible solutions and dedicated support tailored for the B2B client. We partner with clients to provide not just a product, but a comprehensive suspension solution that enhances operational efficiency and longevity.

Customized Solutions and Engineering Support

Recognizing that standard solutions rarely fit every unique operational challenge, we specialize in providing tailored Germany Type Suspension systems. Our engineering team collaborates closely with clients to develop customized solutions that precisely match specific load requirements, trailer chassis designs, and operational environments. This bespoke approach ensures optimal performance and maximum return on investment.

Our customization capabilities include:

- Load Capacity Adjustments: Fine-tuning the leaf spring pack configuration (number of leaves, thickness, arch) to accommodate precise axle load ratings, from standard 12-ton to heavy-duty 16-ton or even higher configurations for specialized applications.

- Axle Spacing and Mount Customization: Modifying axle center distances and hanger bracket designs to integrate seamlessly with various trailer chassis dimensions and multi-axle configurations (tandem, tri-axle, quad-axle setups).

- Material Specification Enhancements: Offering material upgrades for extreme conditions, such as higher alloy content for enhanced strength in ultra-heavy hauling or specialized coatings for unparalleled resistance in highly corrosive environments (e.g., marine transport or chemical processing plants).

- Integrated Component Solutions: Providing complete suspension sub-assemblies including axles, brakes, and wheel-end components, ensuring perfect compatibility and single-source accountability. This simplifies procurement and assembly for trailer manufacturers.

Our dedicated engineering support extends from initial concept development and finite element analysis (FEA) to prototype testing and full-scale production. We leverage decades of experience and robust quality assurance protocols to deliver solutions that are not only high-performing but also fully compliant with international safety and performance standards (e.g., ECE R55, ADR, ISO). Partnering with us means gaining access to expert technical guidance throughout the entire product lifecycle, ensuring your heavy-duty transport solutions are built for enduring success.

Application Case Studies and Success Stories

Real-world application demonstrates the tangible benefits of integrating the Germany Type Suspension into heavy-duty operations. These case studies highlight improved performance, reduced costs, and enhanced safety.

Case Study 1: Heavy-Duty Logistics in Mining Operations

A leading mining conglomerate operating in Western Australia faced persistent challenges with conventional suspension systems on their ore-hauling trailers. The extremely abrasive environment, combined with constant heavy loads (up to 120 tons gross vehicle weight for road trains) and corrugating gravel roads, led to frequent spring breakages, premature bushing wear, and costly unscheduled downtime. Their previous suspension systems typically lasted only 18-24 months before requiring significant overhauls or replacement.

Solution: We collaborated with the client to deploy custom-engineered Germany Type Suspension systems for their new fleet of multi-axle trailers. The solution featured reinforced spring packs using high-grade 60Si2Mn steel, larger diameter hardened pins, and specialized high-wear-resistant polymer bushings. All components received enhanced anti-corrosion and abrasion-resistant coatings.

Results: Over a 36-month operational period, the new trailers equipped with our Germany Type Suspension demonstrated:

- 90% Reduction in Suspension-Related Downtime: Spring breakages and bushing failures were virtually eliminated.

- 50% Extension in Service Life: Projected lifespan increased to 48-60 months, reducing total cost of ownership.

- 10% Improvement in Tire Longevity: Enhanced load distribution and axle alignment reduced uneven tire wear.

- Increased Operational Safety: Drivers reported improved vehicle stability and handling on challenging terrain.

Case Study 2: Petrochemical Tanker Fleet Optimization

A major petrochemical logistics provider in the Middle East sought to upgrade its fleet of chemical tanker trailers. The challenge was two-fold: ensuring maximum safety and stability for hazardous materials transport, while also extending component life in a hot, arid climate with occasional exposure to corrosive substances during loading/unloading operations. Traditional suspension systems showed signs of accelerated corrosion and fatigue, leading to increased inspection requirements and earlier-than-expected replacement cycles.

Solution: We provided Germany Type Suspension systems featuring a specialized corrosion-resistant coating package (multi-stage e-coating followed by heavy-duty powder coat) on all steel components. The leaf springs were specifically designed for dynamic load compensation to manage liquid sloshing effects, enhancing vehicle stability during transit.

Results: After 4 years of continuous service:

- Zero Corrosion-Related Failures: The specialized coatings completely eliminated visible corrosion and associated failures.

- Enhanced Stability: Driver feedback indicated a noticeable improvement in vehicle stability, particularly during braking and cornering, which is crucial for hazardous material transport.

- Reduced Maintenance Costs: The client reported a 35% reduction in suspension-related maintenance costs due to extended component life and fewer unscheduled repairs.

- Compliance with Stricter Regulations: The enhanced durability and stability provided by the suspension system helped the client meet evolving regional safety standards for chemical transport.

Frequently Asked Questions (FAQ)

- Q: What makes Germany Type Suspension systems different from standard heavy-duty suspensions?

- A: The primary difference lies in the robust engineering, use of high-grade materials (e.g., specialized alloy steels, ductile iron for hangers), and stringent manufacturing processes that adhere to elevated European (DIN) and international standards. This results in superior load capacity, extended service life, enhanced stability, and better corrosion resistance compared to many conventional systems.

- Q: Can these suspensions be customized for specific trailer types or load requirements?

- A: Absolutely. Our engineering team specializes in customizing Germany Type Suspension systems. We can adjust load capacities, axle spacing, mounting configurations, and material specifications to perfectly match your unique trailer designs and operational demands, ensuring optimal performance and integration.

- Q: What is the typical service life of a Germany Type Suspension?

- A: With proper maintenance and under normal operating conditions, these systems are designed for an extended service life, typically ranging from 500,000 to over 1,000,000 kilometers. This impressive longevity is a direct result of the high-quality materials and rigorous fatigue testing during manufacturing.

- Q: What maintenance is required for these suspension systems?

- A: While known for their low maintenance, regular inspections of bushings, pins, and leaf springs for wear or damage are recommended. Lubrication of pivot points, as per manufacturer guidelines, is also essential. The durable coatings minimize rust, but any damage to the coating should be addressed promptly to maintain corrosion resistance.

- Q: Are spare parts readily available?

- A: Yes, we maintain a comprehensive inventory of genuine spare parts for all our Germany Type Suspension models. This ensures quick availability and minimizes potential downtime for our clients. We also offer guidance on recommended spare parts inventory for large fleets.

Ordering Information and Support

Lead Time and Fulfillment

Our standard lead time for the Germany Type Suspension system components and standard assemblies typically ranges from 4 to 8 weeks, depending on the order volume and current production schedule. For customized solutions, lead times will be determined after a detailed consultation and engineering review, reflecting the complexity and specific requirements of the design. We prioritize efficient logistics and can arrange various shipping methods to meet your project timelines, including sea, air, and land freight. Expedited options are available upon request and feasibility assessment.

Warranty Commitments

We stand behind the quality and durability of our Germany Type Suspension products with a comprehensive warranty. All suspension systems are covered by a standard 12-month or 100,000-kilometer warranty, whichever comes first, against defects in materials and workmanship. Specific warranty terms may vary for custom-engineered solutions, which will be clearly outlined in your project agreement. Our commitment is to ensure your investment is protected and your operations remain uninterrupted.

Customer Support and After-Sales Service

Our dedication to client success extends far beyond the point of sale. We offer robust customer support and after-sales services designed to maximize the performance and longevity of your suspension systems. This includes:

- Technical Assistance: Access to our team of experienced engineers and technical specialists for installation guidance, troubleshooting, and operational advice.

- Spare Parts Availability: A readily available inventory of genuine replacement parts to ensure prompt repairs and minimize vehicle downtime.

- Maintenance Training: Provision of detailed maintenance manuals and, where feasible, on-site or remote training sessions for your maintenance personnel to ensure proper care and extended component life.

- Feedback and Continuous Improvement: We value customer feedback and incorporate it into our product development cycle, ensuring continuous improvement and innovation in our offerings.

For inquiries, quotations, or technical support, please contact our sales and support team directly through the contact details provided on our website. We are committed to fostering long-term partnerships built on trust and exceptional service.

Authoritative References

- International Organization for Standardization (ISO). (2015). ISO 9001:2015 - Quality management systems - Requirements.

- Deutsches Institut für Normung (DIN). Various DIN Standards related to vehicle components and materials, e.g., DIN 74012 (Leaf Springs).

- Economic Commission for Europe (UNECE). Regulation No. 55 - Uniform provisions concerning the approval of mechanical coupling components of combinations of vehicles.

- Society of Automotive Engineers (SAE International). Various SAE Standards for materials and testing, e.g., SAE J1123 (Leaf Spring Test Procedures).

- American Society for Testing and Materials (ASTM International). Various ASTM Standards for material specifications, e.g., ASTM A536 (Ductile Iron Castings).

-

Durable Germany Type Suspension for Heavy Duty Trucks & Trailers

NewsAug.23,2025

-

American Type Welding Suspension Series: Strong, Reliable Hooks

NewsAug.22,2025

-

Hezhen 1-3mm Luminous Stone- Shijiazhuang Land Auto Component Ltd.|Durability&High Luminosity

NewsAug.18,2025

-

Hezhen 1-3mm Luminous Stone - Shijiazhuang Land Auto Component Ltd.

NewsAug.18,2025

-

Hezhen 1-3mm Luminous Stone - Shijiazhuang Land Auto Component Ltd.|Durable & Versatile

NewsAug.18,2025

-

Hezhen 1-3mm Luminous Stone - Shijiazhuang Land Auto Component Ltd.|Durable Glow-in-the-Dark Solution&Versatile Applications

NewsAug.17,2025