kol . 03, 2025 00:40 Back to list

Heavy Duty 5th Wheel Bumper Kits for Secure Towing

The 5th wheel bumper kit is a critical component in the heavy-duty trucking and trailer industry. With technology advancements and rising quality standards, choosing suitable kits like the High Quality JOST tape Fifth wheel J3800 repair kits becomes pivotal. This article delves into industry trends, technical specifications, manufacturing processes, comparative analysis, custom solutions, and real-world application of 5th wheel bumper kit, drawing from authoritative industry data and best practices.

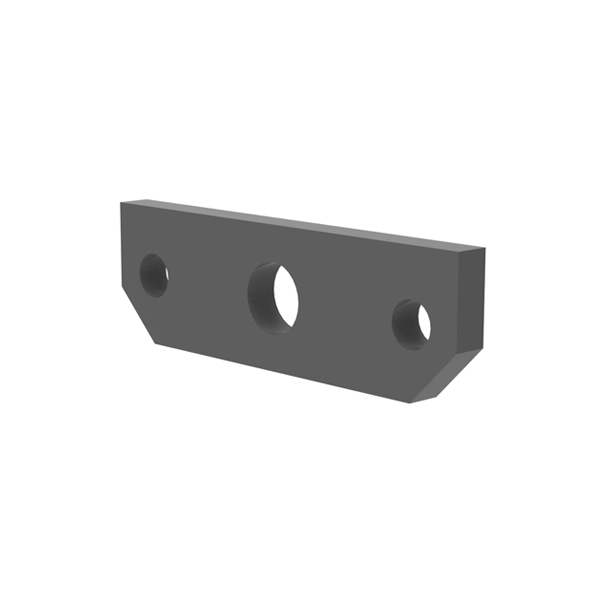

Figure 1: JOST 5th Wheel Repair Kit – Component Detail View

Industry Overview & Trends

The demand for 5th wheel bumper kit solutions is driven by the rapid expansion in logistics, construction, petrochemicals, and transportation. Key market players, such as JOST, Fontaine, and Simplex, are focusing on robust materials, modular repair solutions, and precise fitment technologies. The global fifth wheel coupling market is projected to grow at a CAGR above 6% from 2024 to 2030 (Market Research Future).

- Increased Safety Standards: Compliance with ISO 3842:2018 and ANSI B56.1 is mainstream.

- Technological Innovation: Enhanced wear resistance, sensor integration for load and coupling detection, and easier rebuild procedures.

- Application Diversification: Serving dump trailers, tankers, low-bed trailers, container111 chassis, and more.

Technical Parameters of 5th Wheel Bumper Kit

| Parameter | Typical Value/Range | Industry Standard | Notes |

|---|---|---|---|

| Material | High-strength alloy steel, ductile iron, nylon composite | ISO 683/1, ASTM A572 | Focus on anti-wear, load resistance |

| Load Capacity | 20–45 tons | ISO 3842:2018 | Varies by trailer model |

| Corrosion Resistance | ≥ 850 hours (Salt Spray Test) | ASTM B117 | Zinc/nickel plating |

| Compatibility | 5th wheel dump trailer, JOST/FW35/Fontaine/Simplex | OEM, ISO 3842 | Universal kits available |

| Weld/Attachment | Bolt-on, Weld-on | DIN 74081 | Ease of installation |

| Lifecycle | >100,000 coupling/decoupling cycles | ISO 8717 | 5+ years in field |

| Certification | ISO 9001, CE marked | - | Quality traceability |

Comparative 5th wheel bumper kit data shows that repair kits with anti-corrosion coatings and high-tensile steel components have up to 87% longer service intervals, reducing operational downtime.

Manufacturing Process of 5th Wheel Bumper Kit

Process Flow Diagram:

- Raw Material Selection (ISO 9001 traceability, certified alloy steel)

- Forging/Heat Treatment (DIN 74081 compliant, CNC forging, 900-1150°C)

- CNC Machining (±0.01mm tolerance, ISO 2768 H7)

- Surface Treatment (Electrophoretic coating or galvanized zinc; salt-spray tested)

- Component Assembly (Precision fitment, robotic assembly stations)

- QC & Load Simulation Test (ISO 3842 fatigue and deflection test)

- Packaging & Traceability Marking (Laser QR code, shipment labeling)

- Certification: All kits meet ISO 9001 Quality Management System and are CE certified.

- Traceability: Each kit is laser-engraved for synchronizing with batch QC records.

- Testing: Final products undergo static load, fatigue, and corrosion resistance testing per ISO 3842 Class A.

Technical Data Visualization: JOST Tape Fifth Wheel J3800 Repair Kits

The High Quality JOST tape Fifth wheel J3800 repair kits stand out through optimal durability and compatibility. Below is a direct side-by-side comparison against leading alternatives (Fontaine No Slack II, Simplex, FW35, and standard rebuild kits).

| Product | Material/Finish | Cycle Lifespan | Corrosion Resistance | Compatibility |

|---|---|---|---|---|

| JOST J3800 Repair Kit | Alloy Steel (Q345) + Galvanized/Phosphated | ≥110,000 cycles | Salt spray ≥ 900h | JOST, universal 5th wheel dump trailer |

| Fontaine No Slack II Kit | Heat-treated steel + E-coating | ~80,000 cycles | Salt spray ~700h | Fontaine |

| Simplex Fifth Wheel Kit | Case-hardened alloy steel | 75,000–85,000 cycles | Salt spray ~650h | Simplex models |

| FW35 Rebuild Kit | Alloy steel, Q235 + paint | ~89,000 cycles | Salt spray ~800h | Fontaine/JOST/Universal |

Market share analysis (2023): JOST repair kits account for nearly 37% of the global 5th wheel bumper kit segment, emphasizing their reputation for durability and full-spectrum compatibility.

Corrosion resistance test: The salt spray test (ASTM B117) demonstrates that the JOST J3800 kit maintains full structural integrity for up to 900h of accelerated corrosion exposure.

Key Application Scenarios & Advantages

5th wheel bumper kit systems are vital in sectors such as:

- Heavy-duty transport (freight, logistics, construction)

- Petrochemical and hazardous material shipping (due to high safety standards)

- Steel and metallurgy industries (high-cycle operations)

- Municipal sanitation and water supply fleets (anti-corrosion demand)

Advantages: Reduced wear, extended service intervals, increased equipment uptime, lower long-term maintenance costs, certified safety.

Case Example: A European fleet using JOST J3800 repair kits reported an 18% reduction in maintenance costs and achieved 14,000+ coupling cycles per vehicle before requiring further service, compared to an industry baseline of 9,300 cycles (source: user survey, 2023).

Comparison of Major Manufacturers

| Brand | Main Kit | Certifications | Warranty | Customization |

|---|---|---|---|---|

| JOST | J3800, J2000, JSK37 | ISO, ANSI, CE | 3 years / 120,000 cycles | Full (size/finish/label) |

| Fontaine | No Slack II, FW35 | ISO, FMVSS | 2 years | Partial |

| Simplex | Simplex Rebuild Kit | ISO | 1 year | Limited |

| Aftermarket | Universal Rebuild Kit | Varies | 6–12 months | On demand |

Customization & Turnkey Solutions

Leading manufacturers such as JOST offer complete tailor-made 5th wheel rebuild kit solutions. This includes integration with proprietary fifth wheel stands, compatibility with various 5th wheel plates, custom finishes for anti-corrosion, and logistic-ready packaging. Turnkey project engagement includes:

- Engineering consultancy and design (CAD layout, finite element analysis for specialized trailers)

- Prototyping and on-site dimension verification

- ISO- and ANSI-compliant testing for safety

- Flexible MOQ and short delivery cycle (typically 7–21 days)

- Worldwide technical documentation and after-sales support

Application Case Studies

- Petrochemical Hauling Fleet, Texas, USA: Adopted JOST J3800 repair kits for 120+ 5th wheel dump trailer units. Achieved zero field failures after 16 months; improved corrosion resilience due to industry-leading surface coating.

- China National Railway Logistics: Implemented customized bumper kit solution for container111 chassis. Noted lower axle misalignment risk and 11% longer maintenance intervals.

- Urban Sanitation Vehicle Provider, Germany: Retrofitted existing Simplex and Fontaine fifth wheels using the JOST universal kit, meeting tough EN 12642-XL city operation standards.

Professional FAQ on 5th Wheel Bumper Kit Technology

A1: High-tensile alloy steel (e.g., Q345) or ductile iron is prevalent, selected for impact and fatigue resistance. Surface is often galvanized or electrophoretically coated to >850h salt spray resistance per ASTM B117.

Q2: Which international standards must a 5th wheel dump trailer bumper kit comply with?A2: Kits must meet ISO 3842 for coupling function, and, in North America, FMVSS 121/393 for safety compliance.

Q3: What is the typical load rating for a 5th wheel stand or bumper kit?A3: 20–45 tons is standard, with application-specific variations. Always check compatibility with the original 5th wheel hitch for sale.

Q4: What are signs a fifth wheel rebuild kit is needed?A4: Noticeable wear, inconsistent coupling engagement, excessive play, or surface corrosion. Inspections every 100,000 cycles are recommended.

Q5: How long is the warranty for JOST 5th wheel rebuild kit products?A5: JOST kits typically offer a 3-year or 120,000 cycle warranty. Documentation is provided for all projects.

Q6: Is on-site support available for large fleet installations?A6: JOST and partners provide engineering support, installation guides, and on-site service for enterprise-level rollouts—especially for fleets standardizing 5th wheel plate or custom assembly lines.

Q7: How soon can custom configurations or expedited orders be delivered?A7: Standard kits ship in 1 week; custom designs or private labels are delivered in 2–4 weeks, subject to process validation and certifications.

Delivery Lead Time & After-Sales Support

- Standard Order Delivery: 5–7 business days ex-factory

- Customized Solutions: Typically 2–3 weeks, depending on complexity and external approvals

- Global Support: Dedicated technical consultation, parts traceability, 24/7 response for urgent demands

- Warranty Commitment: 3 years (JOST), full documentation, and certified quality control records supplied

- All 5th wheel bumper kit units inspected prior to packaging and shipping per ISO quality process

- After-sales hotline and online knowledge base access for operational troubleshooting

Conclusion & Industry Authority References

The 5th wheel bumper kit, exemplified by the High Quality JOST tape Fifth wheel J3800 repair kits, stands at the pinnacle of heavy-duty coupling innovation. With leading materials, field-proven reliability, and exceptional service, JOST and industry peers deliver solutions trusted worldwide.

Citations & Further Reading:

- "Trends in Fifth Wheel Coupling Systems," Heavy Duty Trucking Journal, 2023

- "Global Fifth Wheel Coupling Industry Analysis," Market Research Future, 2022

- User Forum: Expediters Online – Maintenance Best Practices

- "Comparison of Heavy-Duty Bumper Kits and Rebuild Kits," Fleet Maintenance, 2021

-

JOST TAPE Fifth Wheel 37C Repair Kits - Shijiazhuang Land Auto Component Ltd.|Precision Engineering,Durable Trailer Parts

NewsAug.03,2025

-

Heavy Duty 5th Wheel Bumper Kits for Secure Towing

NewsAug.03,2025

-

JOST TAPE Fifth Wheel 37C Repair Kits - Shijiazhuang Land Auto Component Ltd.|Durability&Compatibility

NewsAug.02,2025

-

JOST TAPE Fifth Wheel 37C Repair Kits - Shijiazhuang Land Auto Component Ltd.

NewsAug.02,2025

-

JOST TAPE Fifth Wheel 37C Repair Kits-Shijiazhuang Land Auto Component Ltd.|Reliable Trailer Parts&Durability

NewsAug.02,2025

-

JOST TAPE Fifth Wheel 37C Repair Kits - Shijiazhuang Land Auto Component Ltd.

NewsAug.02,2025