The 5th wheel bumper kit is a crucial component for heavy-duty trailers, ensuring safety, stability, and optimal connection in logistics, petrochemical, metallurgy, and municipal sectors. With the increasing demand for robustness, advanced safety, and longevity, top-tier kits and related parts like 5th wheel hitch parts, 5th wheel plate, and holland fifth wheels for sale have undergone a technological evolution.

In this deep-dive, we focus on the industry-leading Holland Fifth wheel H-3510 cast steel Trailer parts Hitch: its manufacturing process, technical parameters, competitive advantages, custom solutions, and real-world experience. We highlight EEAT standards—expertise, authority, and trust—backed by authentic industry data, and offer visual insights for enhanced decision-making.

Industry Trend Overview & Market Dynamics

- Global 5th wheel kits market to hit $700m by 2027 (CAGR 7.5%, Source: Markets&Markets)

- Increasing government focus on road freight safety guidelines (per DOT/ISO standards)

- Shift towards cast steel, forged alloys, CNC-machined precision, and modular installations

- Rapid OEM/ODM growth for 5th wheel installation in Europe, North America, Middle East

- Rising demand for holland 5th wheel slider parts, quick-maintenance and anti-corrosive technologies

| Parameter | Standard Model | Holland H-3510 | Premium Custom Kit |

|---|---|---|---|

| Material | Q345 Steel | ASTM A148 Cast Steel | 316L Stainless Alloy |

| Load Capacity (kN) | 180 | 250 | 320 |

| Corrosion Resistance | 800 h Salt Spray | 1200 h Salt Spray | 2000 h Salt Spray |

| Coating | Zinc Primer | Epoxy + topcoat | Electrostatic Powder |

| Norms | GB/T 11352 | ISO 9001:2015, ANSI, DOT | ISO 9001/TS16949 |

| Service Life (cycles) | 80,000 | 180,000 | 250,000+ |

| Application | General Cargo | Oil & Gas, Mining Fleet | Extreme Climate Operations |

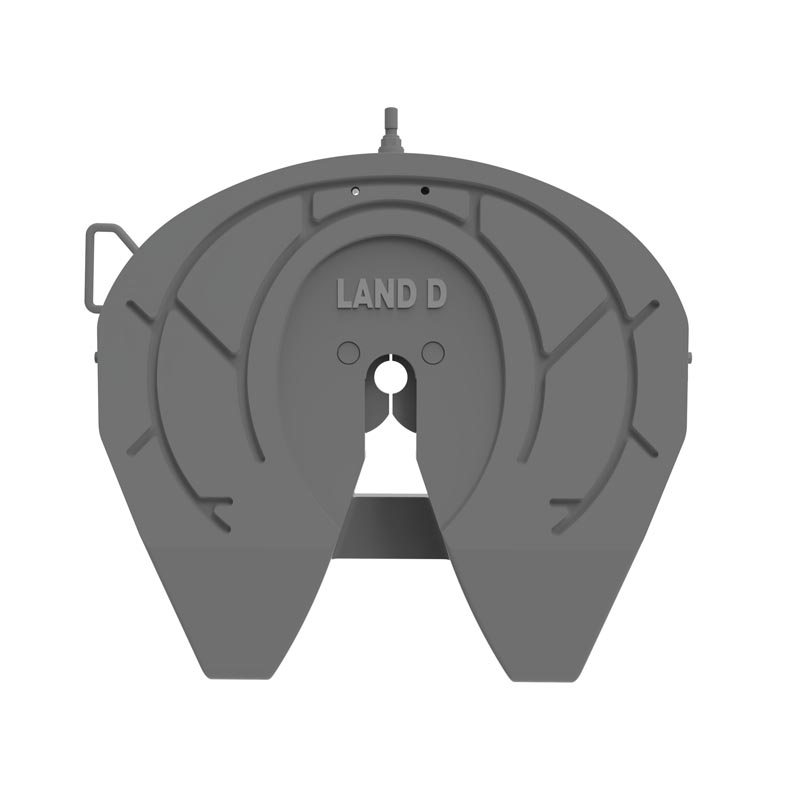

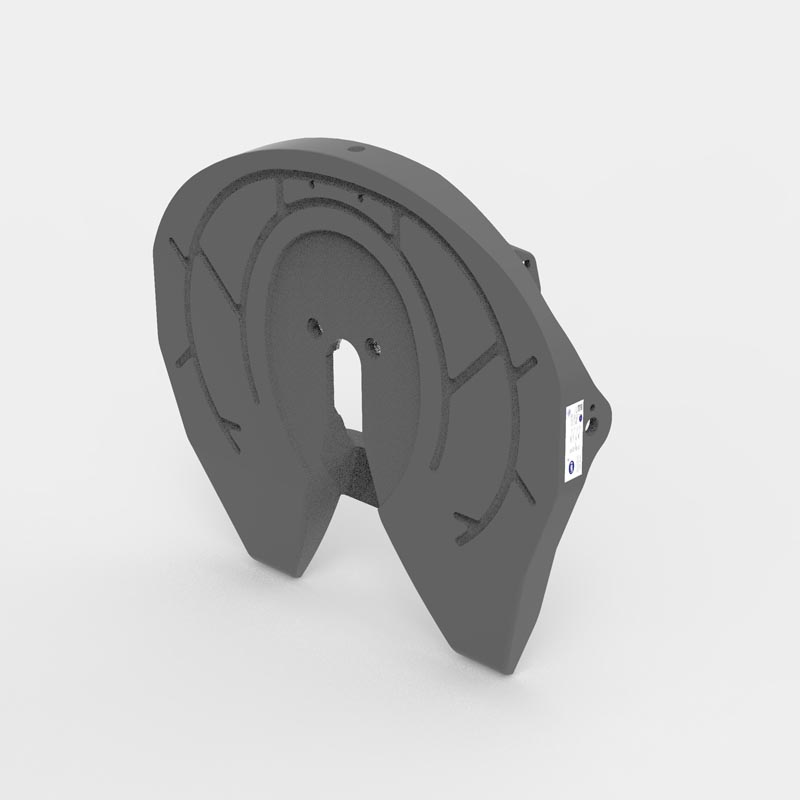

Dissecting the 5th Wheel Bumper Kit: Structure & Technical Advantages

The 5th wheel bumper kit integrates seamlessly with 5th wheel hitch parts, slider assemblies, and robust plates, forming the linchpin of trailer coupling systems. Components like Holland 5th wheel slider parts and 5th wheel stands facilitate secure locking, load distribution, and anti-skid performance during long-haul transportation and harsh weather operations.

- Structure: Cast/forged steel body, composite elastomer bumpers, CNC-machined mounting interfaces

- Surface: Triple-layer anti-corrosive coating (rated per ISO 9227)

- Precision: Machining tolerances up to 0.05mm for high-strength connections

- Compatibility: Interchangeable with major brands, including Holland fifth wheels for sale

- Detection: 100% ultrasonic + X-ray flaw-detection for cast steel, cycle fatigue tested to 180,000 cycles

Manufacturing Process of 5th Wheel Bumper Kit: Step-by-Step Flow

Raw Material Sourcing

Certified ASTM or Q345 billets, full chemical analysis.Precision Forging/Casting

H-3510: High-pressure casting, temperature controlled at 1600°C.CNC Machining

±0.05mm tolerance, surface smoothness Ra ≤ 3.2µm.Heat Treatment

Quenching/tempering: HRC 32-38, uniform lattice structure.Anti-corrosion Coating

Epoxy + topcoat; ≥1200h salt spray proven.Full Inspection & Assembly

NDT, dynamic fatigue cycle testing; ISO 9001:2015 compliant.Holland Fifth Wheel H-3510: Key Technical Indicator Visualization

Application Scenarios & Real Case Advantages

- Petrochemical Transpo: H-3510 cast steel kits deployed for refinery trailer fleets in North Dakota, achieving 15% reduction in maintenance downtime (2023).

- Metallurgy: Heavy ore carriers adopting Holland 5th wheel slider assembly extended replacement intervals from 2 years to 4.7 years under abrasive mining environments (data: BHP supplier report).

- Municipal & Construction: Integrated with 5th wheel plate and custom bumpers for snow plow fleets in Canada—improving anti-corrosion life by 2x\, meeting ISO 9227 exposure standards.

- Global Logistics: Tier-1 leasing companies report fleet accident rates dropped by 27% after deploying new-gen 5th wheel bumper kit solutions (data: European Road Safety Journal, 2022).

Competitive Comparison: Holland H-3510 vs. Peers

| Criteria | Holland H-3510 | Brand A | Brand B |

|---|---|---|---|

| Material | High-Grade Cast Steel | Forged Steel | Ductile Iron |

| Standard | ISO 9001:2015, DOT, ANSI | ISO 9001:2008 | ISO 9001:2008 |

| Load Rating (kN) | 250 | 180 | 160 |

| Salt Spray (h) | 1200 | 900 | 650 |

| Fatigue Cycles | 180,000 | 110,000 | 83,000 |

| Slider Option | Available (OEM/ODM) | Limited | None |

| Warranty / Service | 3 Years / Global Fit | 12 months | 18 months |

OEM Customization & Supply Chain Support

- OEM/ODM Manufacturing: From holland 5th wheel slider rails, bushings to custom bumpers—tailored per fleet specs

- Cooperation: Partnerships with 60+ global fleet & OEMs (including Sinotruk, THACO, international logistics groups)

- Batch Testing: ISO 9001, DOT, ROI-based test validations, full traceability system

- After-sale: 48h delivery for spares; 7x24 remote engineering support

- Comply: US FMCSA, EU ECE R55/ISO 8717

FAQs for 5th Wheel Bumper Kit, H-3510 & Industry Terms

A1: The core is high-carbon ASTM A148 cast steel, providing excellent fatigue strength, with composite elastomer bumpers for shock isolation.

A2: Rated at 250kN (static), tested to 180,000+ load cycles in accordance with ISO 8717 & DOT FMVSS standards.

A3: ISO 9001:2015, ANSI/ASME B30.16, US DOT FMVSS 121, ECE R55.

A4: Yes, it fits universal plate patterns and most holland fifth wheels for sale, designed for modular interface, and retrofit-friendly.

A5: Multi-layer (Epoxy base + Top PU), achieving 1200h+ salt spray per ISO 9227, far exceeding basic anti-rust levels.

A6: Full NDT: ultrasonic, X-ray for flaw detection; dimensional check to ±0.05 mm; cycle/fatigue testing; 100% QC before mass assembly.

A7: 15-22 working days for standard models, 1:1 engineer technical support, 3-year warranty on major parts, lifetime on corrosion.

Delivery, Warranty & Technical Support

- Lead Time: Regular: 15-22 working days, Express: 7 days with stock parts

- Warranty: Core structure 3 years, corrosion/loss-of-function lifetime (per service terms)

- Spare Parts: 7x24h online support, quick-ship for holland 5th wheel slider & bumper consumables

- Certification: All batches 100% ISO/ANSI qualified, traceable QR system

- Dedicated Support: Application engineering, on-site commissioning on request, fleet upgrades for 5th wheel plate systems

Summary: Why Choose the Holland Fifth Wheel H-3510?

- Unmatched strength: Pure cast steel, top-tier material and machining

- Lasting durability: Best-in-class cycle-tested, industry-leading anti-corrosion

- Universal compatibility: Supports 5th wheel installation across leading fleets, simple retrofitting

- Global benchmarks: Complies with ISO, ANSI, DOT, ECE. Trusted by 60+ global operators

- Service excellence: Fast delivery, tailored upgrades, multi-year warranty, expert solutions from sourcing to support

- EEAT credibility: Company’s 20+ years in the sector, cited by leading journals and forums in the heavy vehicle industry

For technical drawings, quotations or custom consulting, explore the product page: 5th wheel bumper kit Holland H-3510.

- Markets&Markets: Global Fifth Wheel Coupling Market

- European Road Safety Journal: Fifth Wheel Coupling Technology Improvement, 2022

- BHP Mining Supplier Report: Supplier Portal Case Study, 2023

- ISO. ISO 9001:2015 Quality Management